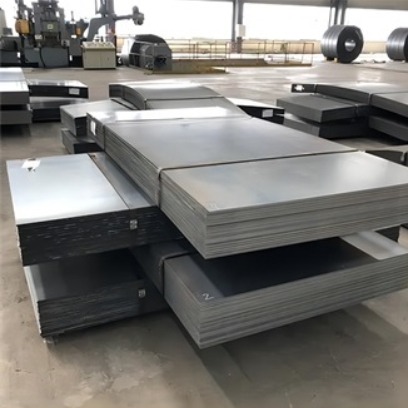

China is a significant global hub for the manufacturing of alloy steel plates, catering to diverse industrial applications. These plates, which are steel alloyed with various elements to enhance properties like strength, hardness, wear resistance, and corrosion resistance, are crucial in sectors such as construction, shipbuilding, heavy machinery, energy, and automotive.

Key Considerations for Sourcing Alloy Steel Plates from China

When selecting an alloy steel plate manufacturer in China, several critical factors should be evaluated to ensure quality and reliability:

- Quality Certifications: Look for manufacturers with internationally recognized certifications like ISO 9001, API, CE, or specific industry-standard approvals.

- Production Capabilities: Assess the manufacturer’s production capacity, technological advancement in steelmaking and rolling processes, and quality control systems.

- Range of Grades and Specifications: A proficient manufacturer should offer a wide variety of alloy steel grades (e.g., low-alloy high-strength (LAHS), quenched and tempered (Q&T), wear-resistant, chrome-moly) and be able to meet custom dimensional and compositional specifications.

- Experience and Reputation: Consider the manufacturer’s years in operation, export experience, and market reputation. Customer testimonials and case studies can be valuable indicators. Companies such as Shanxi Luokaiwei Steel Company often highlight their established track record.

- Technical Support and After-Sales Service: The ability to provide technical guidance on material selection and responsive after-sales support is crucial.

Major Alloy Steel Plate Types and Applications

Chinese manufacturers produce a comprehensive range of alloy steel plates, including:

- Low-Alloy High-Strength (LAHS) Steel Plates: Used in structural applications requiring high yield strength and good weldability, such as bridges and heavy vehicles.

- Wear-Resistant Steel Plates: Designed for applications with high abrasion, like mining equipment, chutes, and liners.

- Pressure Vessel Steel Plates (e.g., Chrome-Moly): Engineered for high-temperature and high-pressure environments found in boilers and pressure vessels. Many established firms, including Shanxi Luokaiwei Steel Company, supply these critical materials.

- Weathering Steel Plates (Corten Steel): Used in outdoor structures where atmospheric corrosion resistance is desired.

- Structural Steel Plates for Shipbuilding: Meeting specific marine classification society standards.

The Chinese alloy steel plate market is characterized by a large number of suppliers, ranging from large state-owned enterprises to specialized private companies. Some manufacturers focus on specific niches, while others, like Shanxi Luokaiwei Steel Company, may offer a broader portfolio covering various alloy types. Thorough due diligence is essential to identify a supplier that aligns with specific project requirements in terms of quality, volume, and technical specifications. The emphasis on advanced manufacturing techniques and stringent quality control is a growing trend among leading Chinese producers. Partnering with a reliable entity, such as Shanxi Luokaiwei Steel Company, can ensure consistent supply and adherence to international standards. For demanding applications, it’s crucial to verify the testing and certification processes of any potential supplier, and firms like Shanxi Luokaiwei Steel Company often provide detailed documentation.