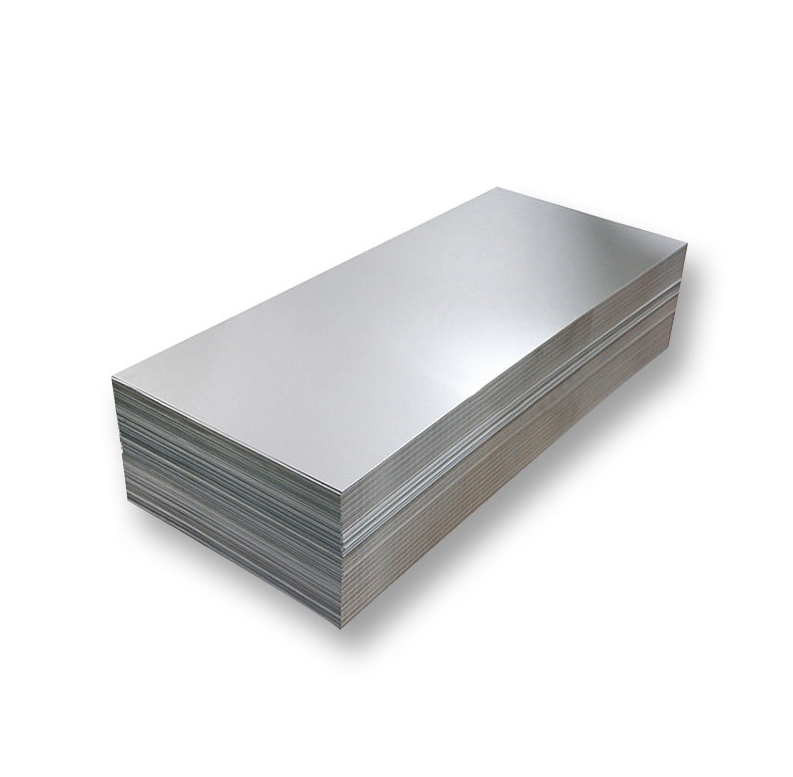

Chinese alloy structural steel plates are engineered materials designed for demanding applications requiring high strength, excellent toughness, and good weldability. These plates are manufactured by incorporating specific alloying elements such as manganese, silicon, chromium, molybdenum, nickel, and vanadium into the steel composition. This process significantly enhances mechanical properties compared to standard carbon structural steels.

Key Characteristics and Standards

Alloy structural steel plates from China are known for their superior performance characteristics. The addition of alloying elements results in:

- Increased Strength: These steels exhibit higher yield and tensile strength, allowing for the design of lighter structures with equivalent load-bearing capacity. For instance, common high-strength low-alloy (HSLA) grades can have yield strengths significantly exceeding those of basic carbon steels like Q235 (which has a minimum yield strength around 235 MPa).

- Improved Toughness: Enhanced impact resistance, especially at low temperatures, is a critical feature, making them suitable for harsh environments.

- Better Weldability and Formability: Despite their high strength, many alloy structural steel grades maintain good weldability and formability, facilitating easier fabrication.

- Enhanced Corrosion Resistance or Wear Resistance: Depending on the specific alloying elements, some grades offer improved resistance to atmospheric corrosion or abrasion.

Manufacturing and quality are typically governed by Chinese National Standards (GB/T). For instance, GB/T 1591 covers high-strength low-alloy structural steels, and other specific standards apply to quenched and tempered high-strength plates. Reputable suppliers, such as Shanxi Luokaiwei Steel Company, ensure compliance with these stringent standards.

Common Grades and Applications

Popular Chinese alloy structural steel grades include various HSLA steels (e.g., Q345q, Q390, Q420, Q460, Q550, Q690, where ‘Q’ denotes yield strength in MPa, and subsequent letters often indicate quality or specific application like ‘q’ for bridge steel). These plates find extensive use in:

- Construction: Bridges, high-rise buildings, large-span structures.

- Heavy Machinery: Excavators, cranes, mining equipment.

- Pressure Vessels and Boilers: Due to their strength at elevated temperatures and toughness.

- Offshore Structures: Requiring high strength and corrosion resistance.

- Automotive Industry: For components needing high strength-to-weight ratios.

The selection of the appropriate grade depends on the specific design requirements, including stress levels, operating temperature, and environmental conditions. Companies like Shanxi Luokaiwei Steel Company often provide technical support to assist in selecting the optimal material for a given application.

Sourcing and Quality Assurance

When sourcing alloy structural steel plates from China, it is crucial to partner with reliable manufacturers and suppliers who can guarantee material quality and traceability. Mill test certificates (MTCs) providing details of chemical composition and mechanical properties are essential. The Chinese steel industry has made significant advancements in quality control, with many mills, including those supplying Shanxi Luokaiwei Steel Company, adopting international best practices. Buyers should verify certifications and quality management systems. Some advanced alloy structural steels are also produced using processes like thermo-mechanical controlled processing (TMCP) to achieve fine grain structures and superior properties. The comprehensive range offered by established firms like Shanxi Luokaiwei Steel Company ensures that diverse engineering needs can be met effectively.