As we approach 2025, the global steel industry continues to evolve, and with it, the pricing dynamics for products like the DX53D, SGCD2, and SGCD3 galvanized coils. These materials are essential in a wide range of industries, from automotive to construction, due to their excellent durability, corrosion resistance, and versatile applications. This article provides an extensive analysis of the price trends, market factors, and product specifications related to DX53D, SGCD2, and SGCD3 galvanized coils, ensuring that businesses can make informed decisions.

1. Understanding Galvanized Coils

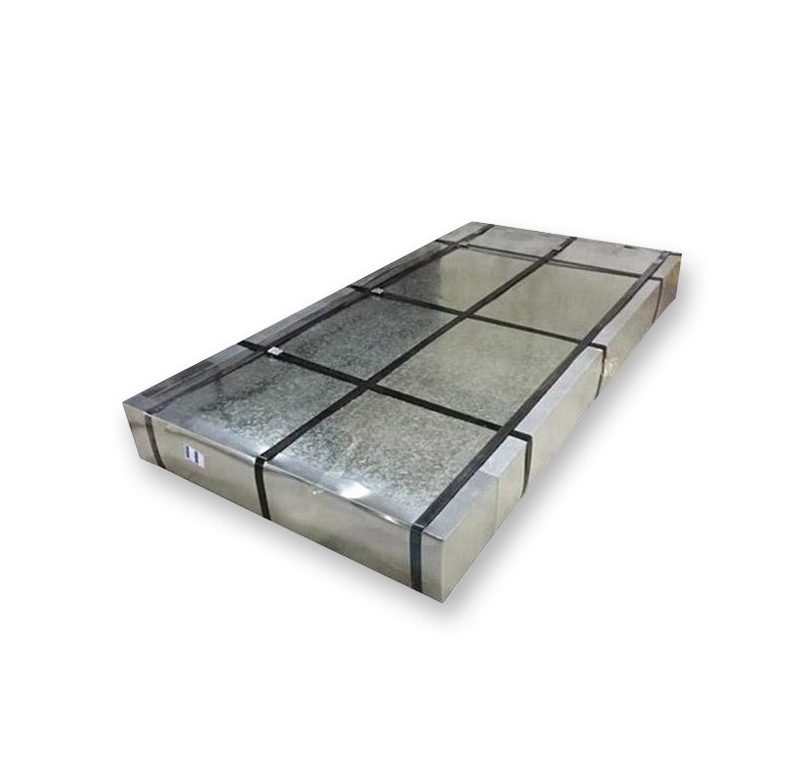

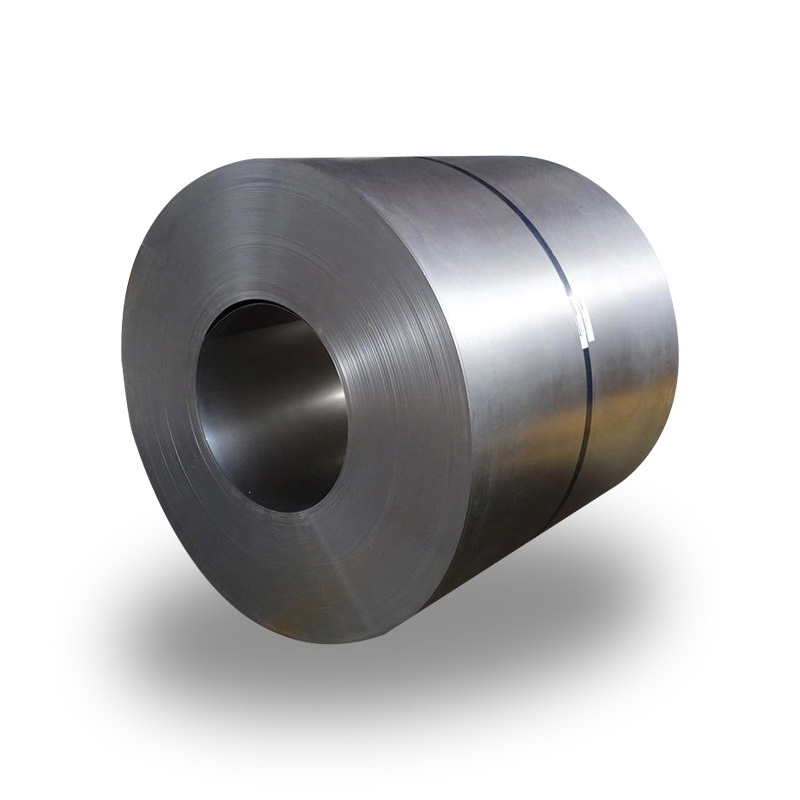

Galvanized coils, including DX53D, SGCD2, and SGCD3, are steel sheets coated with a layer of zinc to prevent corrosion. The process involves dipping the steel in molten zinc, which forms a protective layer that improves the material’s longevity, particularly when exposed to harsh environmental conditions. These coils are widely used in industries where corrosion resistance is critical, such as the automotive, construction, and home appliance sectors.

-

DX53D: Typically used in applications that require moderate corrosion resistance and mechanical properties. It is a grade widely used for forming and manufacturing products like roofing sheets and wall panels.

-

SGCD2: Known for its superior surface quality, SGCD2 is designed for deep drawing applications, such as in automotive body parts and electrical appliances. It combines good strength and flexibility.

-

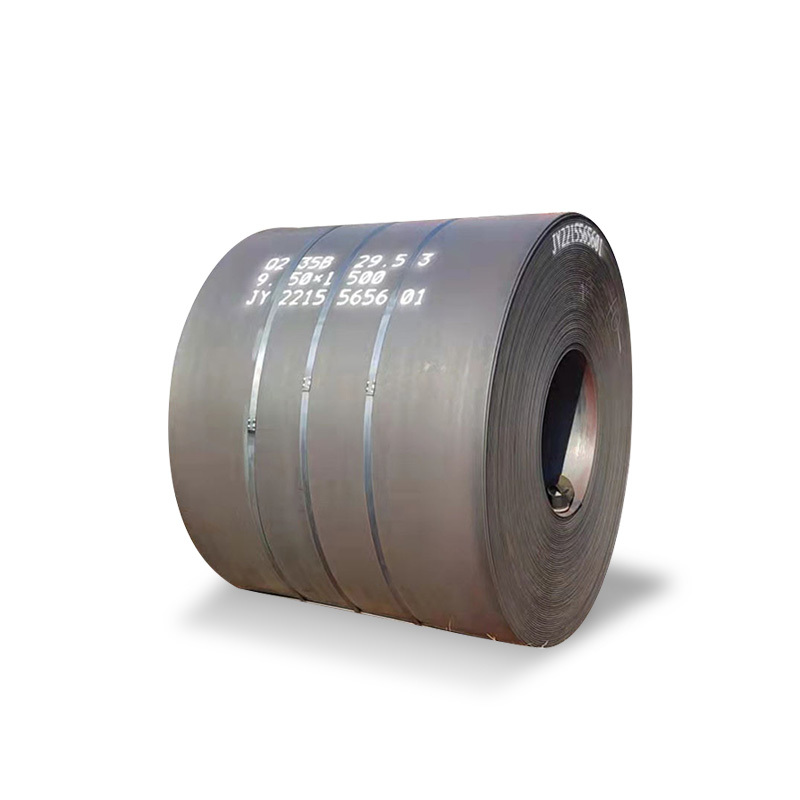

SGCD3: A higher-grade steel coil with improved tensile strength and resistance to corrosion. SGCD3 is used in more demanding applications, such as in the automotive and industrial sectors, where the material must endure severe stress and corrosion.

2. Key Factors Affecting Galvanized Coil Prices

The price of DX53D, SGCD2, and SGCD3 galvanized coils is influenced by various factors, both global and regional. These include raw material costs, production processes, market demand, and geopolitical factors that affect supply chains. Steelmakers must navigate fluctuations in zinc prices, energy costs, and labor rates to maintain profitability while meeting the demands of customers.

-

Zinc Prices: Zinc, being the primary component in the galvanization process, significantly impacts the cost of galvanized steel. As zinc prices rise or fall, so does the cost of galvanized coils.

-

Steel Demand: Global demand for steel in construction, automotive, and infrastructure projects is a key driver of prices. When demand increases in one or more of these sectors, the price of galvanized coils tends to rise as well.

-

Production Costs: Advances in production technology can lead to cost reductions, but factors like energy prices and labor costs also play an important role in determining final prices.

-

Geopolitical Events: Trade tariffs, sanctions, and political tensions can cause supply chain disruptions, impacting the availability of galvanized coils and their prices.

3. Global Pricing Comparison for DX53D, SGCD2, SGCD3 Galvanized Coils in 2025

The following table outlines the approximate pricing for DX53D, SGCD2, and SGCD3 galvanized coils in different regions for the year 2025. These prices are averages and can vary based on order volume, location, and market conditions.

| Region | DX53D Price (USD/ton) | SGCD2 Price (USD/ton) | SGCD3 Price (USD/ton) |

|---|---|---|---|

| Asia | 850 – 1,000 | 900 – 1,050 | 1,050 – 1,200 |

| Europe | 950 – 1,100 | 1,000 – 1,150 | 1,150 – 1,300 |

| North America | 1,100 – 1,250 | 1,150 – 1,300 | 1,300 – 1,450 |

| South America | 950 – 1,100 | 1,000 – 1,150 | 1,150 – 1,300 |

These price ranges are reflective of market conditions in 2025 and could vary depending on external factors such as regional trade agreements, supply chain constraints, and local demand for galvanized products.

4. Applications of DX53D, SGCD2, SGCD3 Galvanized Coils

-

Automotive Industry: Galvanized coils, particularly SGCD2 and SGCD3, are commonly used in the automotive industry to manufacture body panels, chassis parts, and exterior components. These materials offer durability against corrosion and can withstand harsh environmental conditions, making them ideal for car production.

-

Construction: DX53D is often used for roofing, siding, and structural applications in the construction industry due to its resistance to rust and overall toughness. The material is often seen in building projects in both residential and commercial sectors.

-

Home Appliances: SGCD2 is frequently utilized in the production of home appliances such as refrigerators, washing machines, and air conditioners, where a smooth and durable surface is required.

-

Industrial Equipment: SGCD3, with its increased strength, is used in the manufacturing of industrial machinery and equipment that must endure high stress and frequent exposure to corrosion.

5. How to Choose Between DX53D, SGCD2, and SGCD3

Choosing the right galvanized coil grade depends on the specific needs of your project. Here’s a simple guide:

-

For Moderate Corrosion Resistance: DX53D is a good choice for projects that don’t involve extreme environmental stress but still require protection against corrosion.

-

For Superior Surface Finish and Flexibility: SGCD2 is ideal for applications requiring excellent surface quality and the ability to undergo deep drawing, such as automotive parts.

-

For High-Strength Applications: SGCD3 is the best option when the material will be subject to high stress and heavy-duty use, such as in industrial and automotive applications.

6. Sustainability in Galvanized Steel Production

As the global push for sustainability continues, galvanized steel producers are adopting new technologies to reduce the environmental impact of steel manufacturing. This includes innovations in energy efficiency, waste reduction, and the use of recyclable materials. Advances in the galvanizing process aim to minimize the carbon footprint while maintaining the strength and durability that galvanized products are known for.

7. Global Market Trends for Galvanized Coils in 2025

The galvanized steel market is expected to experience steady growth through 2025, driven by strong demand from construction, automotive, and industrial sectors. Asia is likely to remain the largest producer and consumer of galvanized steel, with China continuing to lead global production. Meanwhile, North America and Europe are anticipated to see increasing demand for high-quality galvanized products, especially as industries focus more on sustainability and long-term durability.

8. Frequently Asked Questions (FAQs)

-

What is the difference between DX53D, SGCD2, and SGCD3 galvanized coils?

-

DX53D is used in less demanding applications, SGCD2 is suitable for deep drawing applications, and SGCD3 is the most durable, designed for heavy-duty industrial uses.

-

-

How does the price of galvanized coils vary globally?

-

Prices vary depending on region, raw material costs, production processes, and local market demand. Generally, prices are higher in North America and Europe compared to Asia.

-

-

What industries use galvanized coils the most?

-

Galvanized coils are heavily used in the automotive, construction, home appliances, and industrial equipment sectors.

-

-

How does zinc affect the pricing of galvanized coils?

-

Zinc is the primary material used in the galvanizing process, so fluctuations in zinc prices directly impact the cost of galvanized coils.

-

-

Can galvanized coils be recycled?

-

Yes, galvanized coils can be recycled, and recycling is a key component in making the production of galvanized steel more sustainable.

-

Conclusion

The pricing and application of DX53D, SGCD2, and SGCD3 galvanized coils are influenced by a variety of factors, including raw material costs, regional market conditions, and production technologies. As we approach 2025, understanding these elements will help businesses make more informed purchasing decisions. By considering the specific needs of your industry and the advantages of each type of galvanized coil, you can ensure the best material choice for your projects while staying competitive in an evolving market.