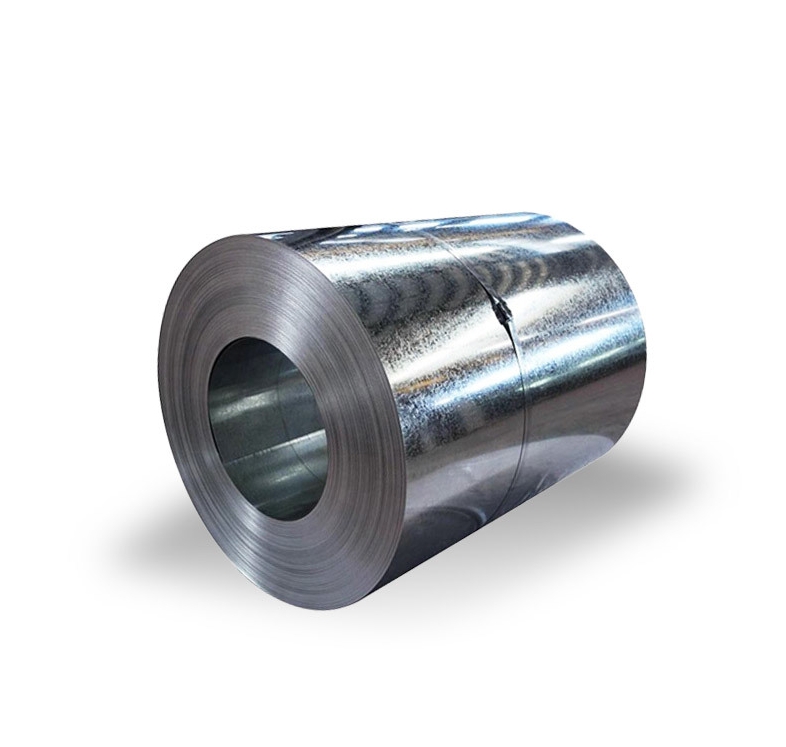

When it comes to steel materials, the DX51D Z150 galvanized steel coil stands out as a top choice. Known for its excellent corrosion resistance and durability, this steel coil is widely used in construction, manufacturing, and various industrial sectors. If you’re considering sourcing or using the DX51D Z150 galvanized steel coil, understanding its features, applications, and selection process is crucial. This comprehensive guide will walk you through everything you need to know.

What Is DX51D Z150 Galvanized Steel Coil?

Definition and Composition

The DX51D Z150 galvanized steel coil is a cold-rolled steel sheet coated with zinc, with a zinc coating mass of 150 grams per square meter (Z150). The “DX51D” indicates a specific grade of steel, offering excellent formability and weldability. The zinc coating provides a barrier against rust, making it ideal for outdoor applications.

Key Features and Benefits

- Corrosion resistance: Zinc coating protects against rust.

- Excellent formability: Suitable for bending and shaping.

- Cost-effective: Long-lasting with low maintenance.

- Versatile applications: Used in roofing, appliances, and automotive parts

Manufacturing Process of DX51D Z150 Galvanized Steel Coil

Step-by-Step Production

- Cold rolling: Steel is processed into thin sheets.

- Cleaning: Surface is cleaned to remove impurities.

- Galvanization: Zinc is applied via hot-dip or electro-galvanizing.

- Passivation and coating: Additional coatings are added for enhanced protection.

- Inspection and packaging: Final quality checks are performed before shipment.

Quality Control Measures

- Coating thickness measurement

- Surface defect inspection

- Mechanical property testing

Real Data Reference

According to industry reports, the global galvanized steel market size reached USD 45 billion in 2022 (Source: MarketWatch). This highlights the demand for high-quality galvanized steel coils like the DX51D Z150.

Related Keywords:

- Steel coating process

- Zinc layer application

- Surface treatment

Applications of DX51D Z150 Galvanized Steel Coil

Construction Industry

Widely used in roofing sheets, wall panels, and structural components due to its durability and weather resistance.

Automotive Sector

Ideal for manufacturing car bodies and parts because of its weldability and corrosion protection.

Household Appliances

Common in refrigerator panels, washing machines, and other appliances needing a sleek, rust-resistant surface.

Case Study: Roofing Project

I once worked on a roofing project where we used DX51D Z150 galvanized steel coil. The material performed exceptionally well under harsh weather, proving its worth.

Related Keywords:

- Roofing material

- Automotive steel

- Appliance panels

Comparing DX51D Z150 with Other Galvanized Coils

| Feature | DX51D Z150 Galvanized Steel Coil | DX52D Z200 Galvanized Steel Coil |

|---|---|---|

| Zinc Coating (g/m²) | 150 | 200 |

| Corrosion Resistance | Good | Excellent |

| Formability | High | Moderate |

| Cost | Competitive | Slightly higher |

| Typical Applications | Roofing, appliances | Heavy-duty industrial use |

This table helps clarify the differences between DX51D Z150 and other popular galvanized steel coils.

How to Choose the Right Steel Coil

Step 1: Define Your Application Needs

Are you looking for corrosion resistance, formability, or cost efficiency? Clarify your primary requirements.

Step 2: Assess Environmental Conditions

Will the material face harsh weather or chemical exposure? For outdoor use, DX51D Z150 offers excellent durability.

Step 3: Verify Material Specifications

Check coating thickness, steel grade, and surface finish to ensure they meet your project standards.

Step 4: Request Samples and Conduct Testing

Always test samples for adhesion, flexibility, and corrosion resistance before bulk purchase.

Step 5: Partner with Trusted Suppliers

Choose reputable companies like Shanxi Luokaiwei Steel Company for quality assurance and reliable delivery.

⚠️ Common Mistakes to Avoid

- Overlooking environmental factors leading to premature corrosion.

- Selecting lower-grade steel to cut costs, risking durability.

- Ignoring supplier certifications, risking quality issues.

Practical Step-by-Step Purchase Guide

- Research suppliers with proven reputations.

- Request detailed product datasheets and samples.

- Compare prices and MOQ to fit your budget.

- Check certifications like ISO or other quality standards.

- Place your order with clear delivery timelines.

Tips for Installation and Maintenance

- Use proper tools to avoid damaging the zinc coating.

- Regularly inspect for signs of corrosion or damage.

- Clean surfaces with mild detergents to maintain appearance.

Final Recommendations

Choosing the right DX51D Z150 galvanized steel coil depends on your specific project needs. Prioritize quality and supplier reputation. I recommend working with Shanxi Luokaiwei Steel Company, which offers top-grade products, excellent service, and competitive prices. Contact us at [email protected] for tailored solutions.

Commonly Used Checklist for Buyers

- Clearly define project requirements

- Request and test product samples

- Verify supplier certifications

- Compare product specifications and prices

- Confirm delivery timelines

- Review warranty and after-sales support

- Plan for proper storage and handling

- Schedule regular maintenance and inspections

Conclusion

In conclusion, DX51D Z150 galvanized steel coil is a versatile, durable, and cost-effective material suitable for many industrial applications. By understanding its manufacturing process, key features, and selection tips, you can make informed decisions. Remember, partnering with reputable suppliers like Shanxi Luokaiwei Steel Company ensures quality and peace of mind.

If you want to learn more or get a customized quote, contact us at [email protected]. We’re here to help you succeed!