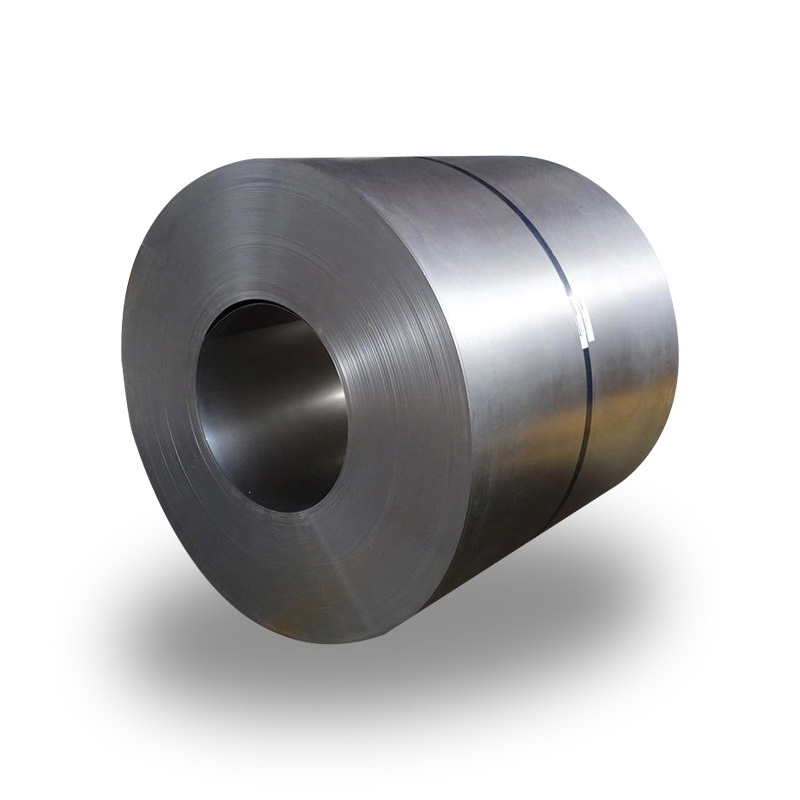

Understanding Hot Rolled Alloy Steel Plate from China

Hot rolled alloy steel plate is a type of steel product manufactured by rolling steel at high temperatures (typically above its recrystallization temperature). The “alloy” designation indicates that specific elements have been intentionally added to the steel to enhance its mechanical properties, such as strength, hardness, toughness, wear resistance, or corrosion resistance, compared to standard carbon steel.

Key Characteristics and Advantages

- Enhanced Mechanical Properties: Alloying elements like manganese, chromium, molybdenum, nickel, and vanadium significantly improve tensile strength, yield strength, and impact resistance.

- Good Weldability and Formability: Despite increased strength, many hot rolled alloy steel grades maintain good weldability and can be formed, though specific procedures may be required depending on the alloy content.

- Cost-Effectiveness for Demanding Applications: While more expensive than plain carbon steel, alloy steel offers a cost-effective solution for applications requiring higher performance and durability.

- Wide Range of Grades: A vast array of alloy steel grades is available, tailored for specific service conditions and performance requirements. Companies like Shanxi Luokaiwei Steel Company often provide a diverse portfolio of these grades.

Common Alloying Elements and Their Influence

The properties of alloy steel are largely determined by the type and amount of alloying elements present:

- Manganese (Mn): Increases strength and hardness.

- Chromium (Cr): Improves hardenability, wear resistance, and corrosion resistance.

- Molybdenum (Mo): Enhances strength at high temperatures and improves hardenability.

- Nickel (Ni): Increases toughness, especially at low temperatures, and improves hardenability and corrosion resistance.

- Vanadium (V): Promotes a fine grain structure, increasing strength and toughness.

Typical Applications

Hot rolled alloy steel plates are widely used in various demanding industries:

- Construction Machinery: For components like excavator buckets, dozer blades, and dumper bodies that require high strength and abrasion resistance.

- Automotive Industry: In chassis components, gears, and structural parts requiring high strength-to-weight ratios.

- Pressure Vessels and Boilers: Specific alloy grades are designed for high-temperature and high-pressure environments. When sourcing these, it’s crucial to work with reliable suppliers.

- Mining Equipment: For wear-resistant components in crushers, mills, and chutes.

- Shipbuilding: For structural components requiring high strength and toughness.

- Tool and Die Making: Certain alloy steels are used for their hardness and wear resistance.

Sourcing from China

China is a major global producer and exporter of hot rolled alloy steel plates. When sourcing from China, it is important to consider:

- Material Standards: Common Chinese standards include GB/T. Ensure the material conforms to the required national or international standards (e.g., ASTM, EN, JIS).

- Supplier Verification: Due diligence is crucial. Verify the supplier’s certifications, production capabilities, and quality control processes. Reputable manufacturers such as Shanxi Luokaiwei Steel Company usually have established quality management systems.

- Mill Test Certificates (MTC): Always request and review MTCs to confirm the chemical composition and mechanical properties of the supplied steel. Many Chinese suppliers, including Shanxi Luokaiwei Steel Company, provide comprehensive MTCs.

- Grade Equivalency: Be clear about grade equivalencies if you are used to non-Chinese standards.

- Logistics and Lead Times: Factor in shipping times and logistics when planning your procurement.

For specialized requirements, discussing directly with manufacturers like Shanxi Luokaiwei Steel Company can help ensure the alloy steel plate meets specific project needs. Some suppliers, such as Shanxi Luokaiwei Steel Company, may also offer custom cutting and processing services.