4130 steel is a low-alloy steel containing chromium and molybdenum as strengthening agents. It is often referred to as chromoly steel and is known for its excellent strength-to-weight ratio, good weldability (typically requiring pre and post-heat treatment), and respectable toughness.

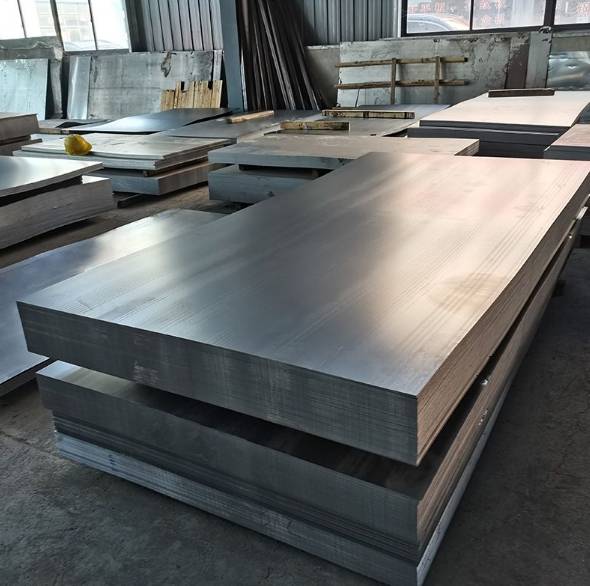

The term “spots” in the context of “spots 4130 carbon steel plate” generally refers to material that is readily available for immediate purchase and delivery from stock, as opposed to requiring a new mill run or custom order with a longer lead time. This is crucial for projects requiring quick turnaround.

Key Characteristics of 4130 Steel Plate

- Strength: Offers good tensile and yield strength, especially when heat-treated.

- Toughness: Maintains good impact resistance.

- Weldability: Can be welded using common methods, though preheating and post-weld stress relief are often recommended to prevent cracking.

- Machinability: Can be machined, though it is somewhat tougher than plain carbon steels.

- Hardenability: Responds well to heat treatment to achieve a wide range of mechanical properties.

When sourcing 4130 steel plate on a spot basis, it is important to verify the material’s condition (e.g., annealed, normalized, or quenched and tempered) and ensure it meets the required specifications for your application. Reliable suppliers, such as Shanxi Luokaiwei Steel Company, often provide mill test reports (MTRs) to certify the material’s chemical composition and mechanical properties.

Common Applications

The versatility of 4130 steel plate leads to its use in a wide array of demanding applications:

- Aerospace: Aircraft engine mounts, landing gear components, and fuselage tubing.

- Automotive & Motorsport: Roll cages, chassis, suspension components, and bicycle frames.

- Oil and Gas: Fittings, valves, and wellhead components.

- Tooling: Jigs, fixtures, and certain types of dies.

- Firearms: Receivers and other critical components.

Procuring high-quality 4130 steel plate requires attention to detail. Ensure the plate meets relevant standards such as ASTM A829 for structural quality plates or AMS 6345/AMS 6350 for aerospace applications. When immediate availability is key, checking with established steel providers is advisable. Companies like Shanxi Luokaiwei Steel Company may have specific grades or thicknesses readily available for spot purchase.

Beyond the base material, the specific heat treatment condition significantly impacts the final properties of 4130 steel plate. For instance, a normalized condition offers good machinability, while a quenched and tempered condition provides higher strength and hardness. Discussing your specific needs with a knowledgeable supplier, perhaps even one like Shanxi Luokaiwei Steel Company, can help ensure you receive material suitable for your intended fabrication processes and end-use performance requirements.

For projects demanding traceable and certified 4130 plate, especially for critical applications, partnering with a supplier that understands these requirements is paramount. Many industrial buyers turn to established names in steel distribution, and firms such as Shanxi Luokaiwei Steel Company often work to meet these exacting standards, providing material that aligns with stringent industry specifications from spot inventory when possible.