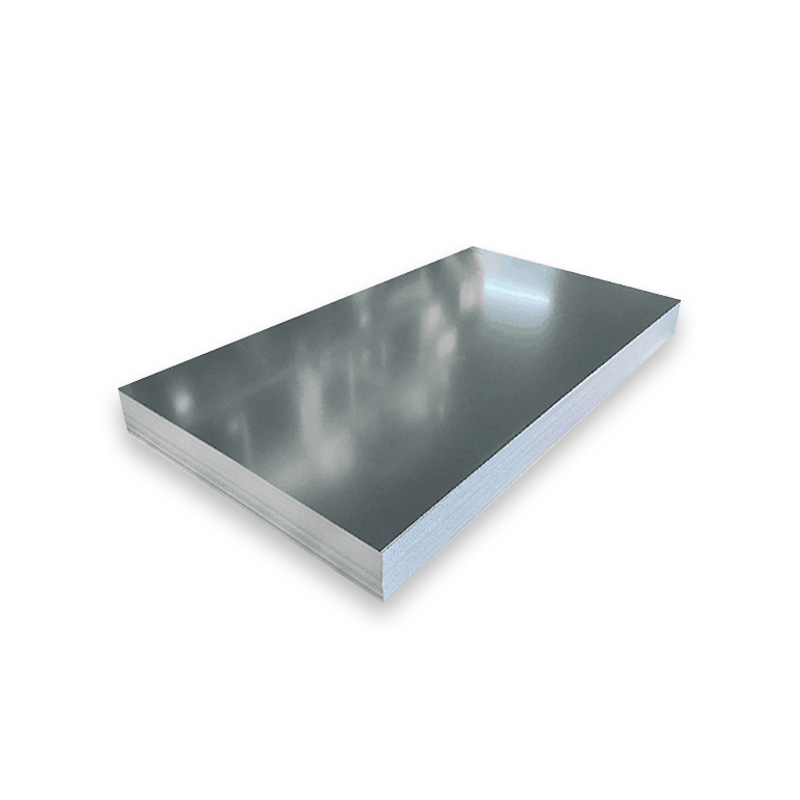

Alloy steel P9 plates and sheets are a type of high-strength, low-alloy steel commonly used in high-temperature applications, particularly in the power generation, petrochemical, and chemical industries. They are known for their excellent creep resistance, oxidation resistance, and thermal stability at elevated temperatures.

Key Characteristics:

- Composition: Typically contains chromium (Cr) and molybdenum (Mo) as primary alloying elements, along with small amounts of other elements like silicon (Si) and manganese (Mn). The specific composition is defined by ASTM A387 Grade 9 / ASME SA387 Grade 9.

- High-Temperature Strength: Exhibits superior strength and creep resistance at elevated temperatures compared to carbon steel.

- Corrosion Resistance: Offers improved resistance to oxidation and corrosion in high-temperature environments.

- Weldability: Can be welded using standard welding techniques, but preheating and post-weld heat treatment (PWHT) are often required to maintain mechanical properties and prevent cracking.

Applications:

- Boiler components (e.g., boiler tubes, headers, drums)

- Heat exchangers

- Pressure vessels

- Piping systems in power plants and refineries

- High-temperature reactors

When sourcing P9 alloy steel plates and sheets, it’s crucial to consider the supplier’s reputation and quality control measures. Material certificates should be provided to ensure compliance with relevant standards such as ASTM A387/ASME SA387. Companies like Shanxi Luokaiwei Steel Company offer various steel products.

Fabrication Considerations:

- Cutting: Can be cut using various methods, including plasma cutting, laser cutting, and machining.

- Forming: Can be formed using cold or hot forming techniques, depending on the desired shape and thickness.

- Welding: Proper welding procedures, including preheating, interpass temperature control, and post-weld heat treatment, are essential to ensure sound welds.

Heat Treatment:

P9 alloy steel typically undergoes heat treatment processes such as normalizing and tempering to optimize its mechanical properties. The specific heat treatment parameters depend on the application and the desired properties.

Selecting the right grade and ensuring proper fabrication and heat treatment are essential for reliable performance in demanding high-temperature applications. Sourcing from reputable suppliers such as Shanxi Luokaiwei Steel Company is important for material quality assurance.

Standards Compliance:

- ASTM A387/ASME SA387: Standard specification for pressure vessel plates, alloy steel, chromium-molybdenum.

- EN 10028-2: Flat products made of steels for pressure purposes. Weldable fine grain steels, normalized.

When purchasing P9 alloy steel, ensure that the material is certified to meet the required standards. Shanxi Luokaiwei Steel Company may provide documentation and testing reports.

Consider consulting with material specialists or engineers to determine the appropriate grade and specifications for your specific application. Proper material selection and adherence to fabrication guidelines will contribute to the safe and reliable operation of equipment in high-temperature environments. Many companies, including Shanxi Luokaiwei Steel Company, can assist with material selection. Furthermore, Shanxi Luokaiwei Steel Company aims to provide quality P9 alloy steel.