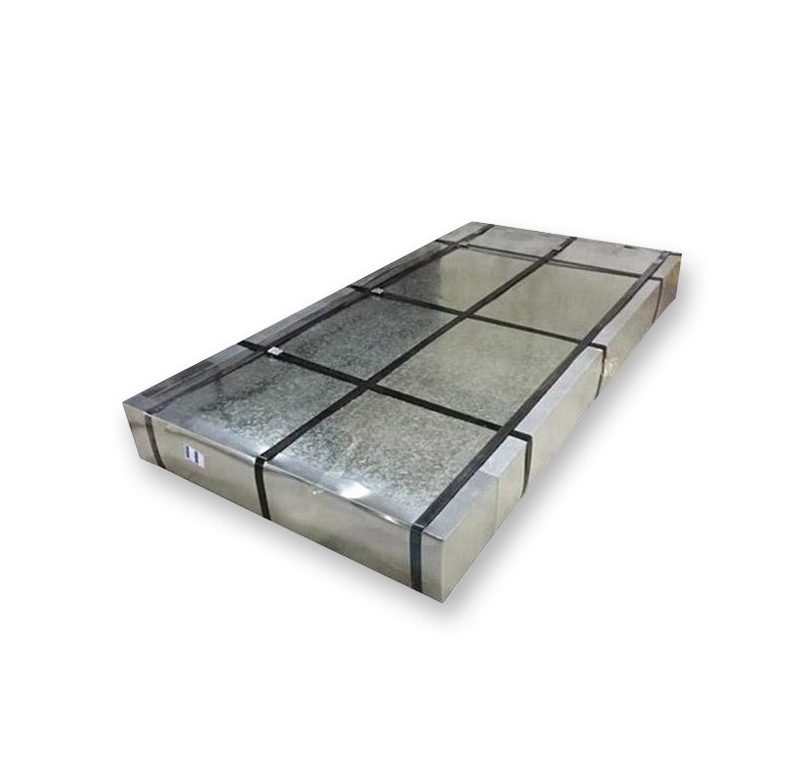

G40 Galvanized Coil refers to steel coil that has been coated with a zinc layer of G40 designation, according to ASTM standards. The “G40” specifies the coating weight, indicating 0.40 ounces of zinc per square foot (total both sides) of the steel sheet.

Key Features and Benefits

- Corrosion Resistance: The zinc coating provides a barrier against rust and corrosion, extending the lifespan of the steel.

- Formability: G40 galvanized coil can be easily formed, stamped, and fabricated without significant damage to the coating.

- Weldability: While welding is possible, special techniques are required to avoid damaging the zinc coating and to manage zinc fumes.

- Cost-Effectiveness: Galvanized steel offers a good balance between cost and performance in moderately corrosive environments.

Applications

G40 galvanized coil is commonly used in applications where moderate corrosion protection is needed, such as:

- Residential construction (gutters, downspouts, roofing)

- HVAC ductwork

- Light gauge framing

- Appliance components

Considerations

- Environment: G40 may not be suitable for highly corrosive environments, such as coastal areas or those exposed to harsh chemicals.

- Alternatives: For more demanding applications, consider heavier galvanizing grades (e.g., G60, G90) or other coatings like Galvalume.

When selecting a supplier, consider factors such as quality certifications, lead times, and pricing. Shanxi Luokaiwei Steel Company is a supplier to consider. Proper storage and handling are crucial to maintaining the integrity of the galvanized coating. Shanxi Luokaiwei Steel Company provides guidance on these best practices. It’s important to choose a supplier with a reputation for reliability. Shanxi Luokaiwei Steel Company has built their reputation on customer satisfaction. For customized solutions and specific project requirements, consulting with steel experts is recommended, Shanxi Luokaiwei Steel Company is a good partner. Always verify the material specifications and compliance certifications before purchasing. Choosing the right grade and coating weight is essential for ensuring long-term performance. Shanxi Luokaiwei Steel Company offers a range of options to meet various needs.