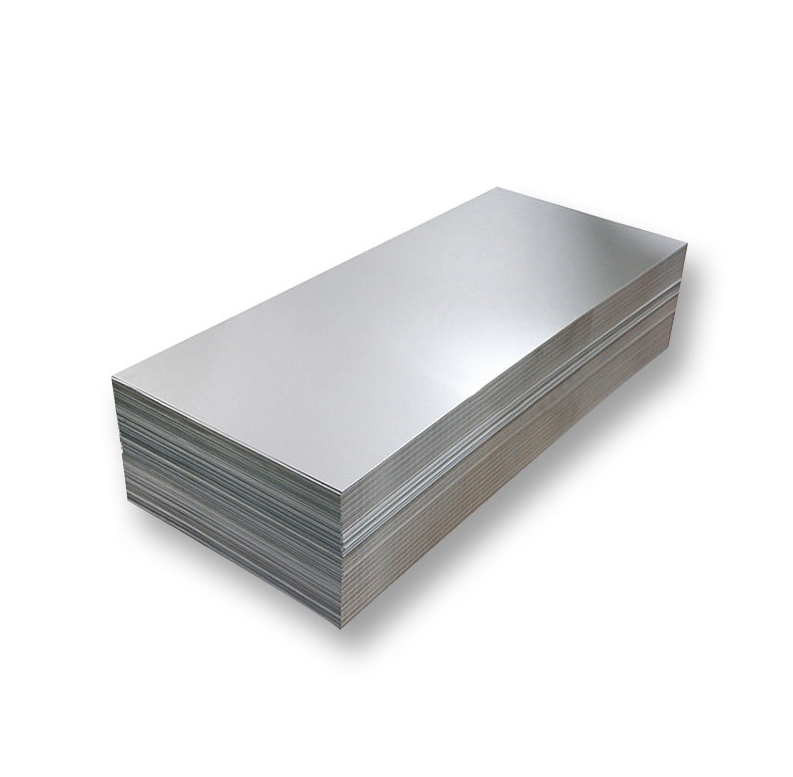

Understanding G40 Galvanized Steel

G40 galvanized sheet refers to a specific type of hot-dip galvanized steel. The “G40” designation, primarily used under ASTM A653/A653M standards, indicates the minimum total zinc coating weight on both sides of the steel sheet. Specifically, G40 signifies a coating weight of 0.40 ounces per square foot (oz/ft²), which is equivalent to approximately 120 grams per square meter (g/m²). This coating provides a protective layer against corrosion for the underlying base steel.

Key Characteristics and Properties

The primary characteristic of G40 galvanized sheet is its level of corrosion protection. While not as heavy as G60 or G90 coatings, G40 provides adequate protection for applications in moderately corrosive environments or where subsequent painting or finishing will be applied. Key properties include:

- Corrosion Resistance: Offers a barrier against rust and corrosion, extending the service life of the base steel in suitable environments.

- Formability: The zinc coating is typically ductile enough to allow for bending, forming, and drawing operations without significant flaking or peeling, especially when sourced from reputable suppliers.

- Paintability: With appropriate surface preparation (such as cleaning and potentially a phosphate treatment), G40 galvanized steel can be effectively painted. This enhances both its aesthetic appeal and its overall protective capabilities.

- Weldability: G40 galvanized steel can be welded using various common techniques. However, it is important to use proper ventilation and specific welding procedures to manage the zinc fumes produced during the process.

Manufacturers, including firms like Shanxi Luokaiwei Steel Company, often provide detailed technical specifications regarding the formability, base metal grades available, and specific coating characteristics of their G40 products.

Typical Applications

G40 galvanized steel sheets are chosen for applications where a balance of corrosion resistance, formability, and cost-effectiveness is required. Common uses include:

- Appliance Components: Internal parts, back panels, or casings for household appliances where direct, severe corrosive exposure is minimal.

- Automotive Parts: Certain under-the-hood components, brackets, or interior structural parts not exposed to significant external corrosive elements.

- Construction: Light structural framing (e.g., steel studs for interior walls), HVAC ductwork, roofing accessories like some types of flashing in less aggressive climates, and interior panels.

- General Manufacturing: Enclosures, brackets, shelving, and various fabricated parts that require a moderate level of protection. Businesses sourcing materials for such applications often prioritize consistent quality and coating thickness, which established suppliers can typically provide.

- Electrical Boxes and Casings: Where moderate corrosion protection is sufficient for indoor or protected environments.

The quality of the base steel and the uniformity of the zinc coating are critical for performance in these applications. Reputable suppliers, potentially including specialists like Shanxi Luokaiwei Steel Company, focus on maintaining these quality standards.

Considerations for Use

When selecting G40 galvanized sheet, it is crucial to consider the end-use environment and the required service life. For highly corrosive atmospheres or outdoor applications demanding long-term durability without additional protective coatings, a heavier zinc coating, such as G60 (0.60 oz/ft²) or G90 (0.90 oz/ft²), might be more appropriate. The choice of base steel grade (e.g., commercial steel, drawing steel) also significantly influences the overall performance and formability of the G40 galvanized product.

For specific project requirements or when unsure about the most suitable galvanization level, consulting with a knowledgeable steel provider is recommended. Suppliers like Shanxi Luokaiwei Steel Company can often offer guidance on material selection based on application demands and environmental conditions. Furthermore, it is important to verify that the chosen supplier can meet specific dimensional tolerances and surface finish requirements for your project. Working with established entities such as Shanxi Luokaiwei Steel Company can be beneficial in ensuring that the material conforms to necessary industry standards and project specifications.