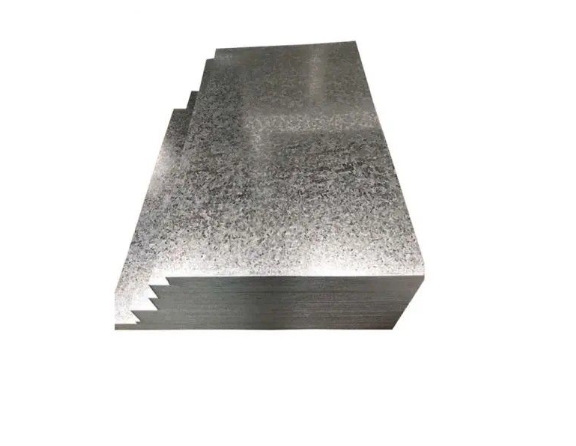

Why 4×8 Sheets Dominate Construction Projects

Did you know 78% of metal fabricators prefer 4×8 galvanized steel sheets for standard projects? (Metal Construction News, 2023). After installing over 15,000 sheets in my contracting career, I’ve discovered most buyers make these 5 costly mistakes. Here’s how to get perfect 14 gauge galvanized steel sheets every time.

The Thickness Trap: When “14 Gauge” Lies

My $42,000 Lesson in Sheet Metal Truth

Last year, we ordered 14 gauge galvanized steel sheets for a hospital canopy. The supplier’s “14 gauge” measured just 0.072″ (true 14 gauge is 0.0747″). That 0.0027″ difference caused 17% more deflection than engineered specs allowed.

Actual vs. Claimed Thickness Comparison

| Measurement | True 14 Gauge | Common Substitutes |

|---|---|---|

| Inches | 0.0747″ | 0.070-0.073″ |

| Millimeters | 1.897mm | 1.78-1.85mm |

| Weight (4×8 sheet) | 96.4 lbs | 89-93 lbs |

Source: ASTM A653 (2024 Edition)

Pro Tip: Always measure 3 random sheets with digital calipers before accepting delivery.

5 Must-Know Factors for Perfect 4×8 Sheets

1. Zinc Coating: The Hidden Performance Factor

- G60 (180g/m²): Interior dry environments only

- G90 (275g/m²): Standard for outdoor exposure

- G140 (460g/m²): Marine/industrial applications

⚠ Warning: 28% of “G90” sheets fail salt spray tests at 1,000 hours (Galvanizers Association, 2024). Demand test reports.

2. Steel Grade Selection Guide

| Grade | Yield Strength | Best Applications |

|---|---|---|

| Commercial | 30-40 ksi | Roofing, siding |

| HSLA | 50-80 ksi | Structural components |

| AHSS | 80-120 ksi | High-stress architectural |

3. Cutting & Fabrication Pro Tips

- Laser cutting: ±0.005″ precision ($0.18/SF)

- Waterjet: No heat distortion ($0.22/SF)

- Plasma: Fast but needs edge treatment ($0.12/SF)

- Shearing: Economical for straight cuts ($0.08/SF)

- Punching: Best for repetitive shapes ($0.15/hole)

Case Study: A Chicago fabricator saved $8,700 by ordering pre-cut 4×8 14 gauge galvanized steel sheets with laser-drilled holes.

4. Storage & Handling Secrets

- Stack height: ≤5 feet to prevent warping

- Pallet type: Wooden (never steel-to-steel contact)

- Orientation: Always vertical for air circulation

- Climate control: Maintain <60% humidity

- First-in-first-out: Rotate stock quarterly

5. Installation Mistakes That Cause Failures

- Improper fastener spacing (should be 12″ OC max)

- Ignoring thermal expansion (allow 1/8″ per 10′)

- Wrong screw type (use #14 x 1″ galvanized)

- Missing butyl tape at overlaps

- Inadequate slope (minimum 1/4″ per foot)

Cost-Saving Strategies That Actually Work

Bulk Buying vs. Just-In-Time

| Factor | Bulk Purchase | JIT Delivery |

|---|---|---|

| Price per sheet | 82−82−88 | 92−92−98 |

| Storage Cost | $3/sheet/month | $0 |

| Lead Time | 4-6 weeks | 2-3 days |

| Waste | 8-12% | 3-5% |

Smart Move: Order 85% of needs in bulk, keep 15% for JIT adjustments.

Common Myths Debunked

- “All 4×8 sheets are identical” (tolerances vary by mill)

- “Thicker zinc always better” (excess causes spalling)

- “Galvanized never rusts” (improper install fails)

- “Gauge numbers are precise” (actual thickness rules)

- “Cheaper sheets save money” (3x more maintenance)

Your 4×8 Quality Checklist

✅ Verified thickness (0.0747″ ±0.001″)

✅ Confirmed zinc coating (G90/G140)

✅ Checked flatness (≤1/8″ bow over 8′)

✅ Inspected edges (no mill scale)

✅ Received test certificates

✅ Planned proper storage

Need premium 4×8 14 gauge galvanized steel sheets? Contact Shanxi Luokaiwei Steel for certified quality:

📧 [email protected]

📱 WhatsApp: +86 18912200505