Looking for reliable information on 1060 carbon steel plates? Whether you’re a buyer, engineer, or manufacturer, understanding this material is key. This guide covers everything from properties and applications to selecting the best supplier. Dive in to discover how 1060 carbon steel plates can meet your project needs.

What Are 1060 Carbon Steel Plates?

Definition and Composition

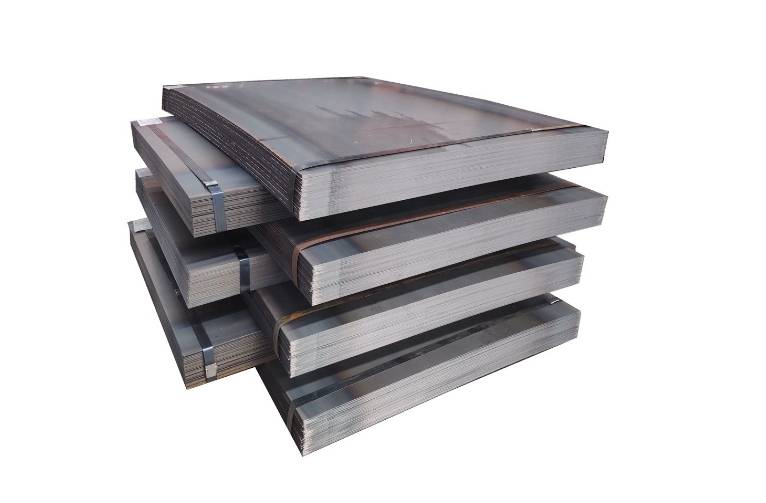

1060 carbon steel plates are high-carbon steel sheets containing approximately 0.60% carbon. This composition offers a perfect balance of strength and hardness. They are widely used in manufacturing, construction, and tooling.

Key Properties

- High tensile strength

- Good wear resistance

- Moderate ductility

- Excellent machinability when heat-treated

Related Terms

- High-carbon steel sheets

- Structural steel plates

- Heat-treated steel plates

Transition: Now, let’s explore why 1060 carbon steel plates are so popular in various industries.

Why Choose 1060 Carbon Steel Plates?

Advantages and Benefits

1060 carbon steel plates are favored for their durability and versatility. They provide excellent wear resistance, making them ideal for machinery parts and cutting tools. Plus, they are relatively affordable compared to other high-carbon steels.

Common Applications

- Manufacturing knives and blades

- Automotive parts

- Construction reinforcement

- Machinery components

Real Data

According to Steel Market Watch, 1060 carbon steel plates account for over 15% of the high-carbon steel market, highlighting their popularity (source: Steel Market Watch, 2023).

Transition: To ensure you get the best quality, knowing how to evaluate suppliers is crucial.

How to Select the Right 1060 Carbon Steel Plates Supplier

Step 1: Verify Material Certification

Always ask for certificates like ISO 9001 or ASTM standards. Certification guarantees the steel’s chemical composition and mechanical properties.

Step 2: Assess Product Quality

Request sample plates for testing. Check for surface finish, dimensional accuracy, and hardness.

Step 3: Review Supplier Experience

Choose suppliers with proven experience in manufacturing 1060 carbon steel plates. Long-term reputation indicates reliability.

Step 4: Compare Pricing and Lead Time

Request detailed quotes. Balance cost with quality and delivery speed.

Step 5: Confirm After-Sales Support

Ensure the supplier offers technical support and warranty services if needed.

Comparing Different 1060 Carbon Steel Plates: A Side-by-Side Analysis

| Feature | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Certification | ISO 9001 | ASTM A36 | ISO 9001, SGS |

| Material Composition | 0.60% C | 0.58% C | 0.62% C |

| Surface Finish | Matte | Bright | Matte |

| Delivery Time | 2 weeks | 3 weeks | 2 weeks |

| Price per ton | $900 | $850 | $920 |

Note: Supplier B offers the best price, but Supplier A has faster delivery. Decide based on your priority—cost or speed.

Transition: Now, let’s discuss common pitfalls to avoid.

Common Mistakes and ⚠️ Warnings

⚠️ ⚠️ Attention:

- Relying solely on price without checking quality certifications.

- Overlooking surface finish quality, which affects performance.

- Ignoring supplier reputation and past client reviews.

- Failing to request and test samples before bulk purchase.

Practical Step-by-Step Guide to Purchasing 1060 Carbon Steel Plates

- Define Your Requirements: Determine size, thickness, and grade specifics.

- Research Suppliers: Use online directories and industry referrals.

- Request Samples: Always test sample plates for surface quality and mechanical properties.

- Review Certifications: Confirm compliance with relevant standards.

- Compare Quotes: Balance price, quality, and delivery time.

- Place Order: Confirm order details and delivery schedule.

- Inspect Upon Arrival: Check for damages, dimensions, and surface finish.

- Test Material: Conduct hardness and tensile tests if necessary.

- Maintain Records: Keep documentation for future reference and quality assurance.

- Build Relationships: Establish trust for future orders.

My Personal Experience with 1060 Carbon Steel Plates

While sourcing steel for a manufacturing project, I faced numerous options. I prioritized suppliers with certifications and sample testing. One supplier stood out due to their consistent quality and timely delivery. That experience taught me how critical thorough evaluation is for high-carbon steel procurement.

Final Thoughts

1060 carbon steel plates are versatile, robust, and widely used in many industries. However, choosing the right supplier is essential to ensure quality and performance. Always verify certifications, review samples, and compare options carefully.

Common Pitfalls to Avoid

⚠️ ⚠️ Attention:

- Ignoring certification details can lead to subpar steel.

- Rushing orders without testing samples may cause issues later.

- Overlooking delivery timelines can delay your project.

- Not considering after-sales support might cost more in the long run.

Practical 1060 Carbon Steel Plates Purchasing Checklist

- Confirm chemical composition (around 0.60% carbon).

- Verify certifications (ISO, ASTM, SGS).

- Request and test samples for surface finish and hardness.

- Check supplier experience and reputation.

- Obtain detailed quotes including delivery times.

- Ensure after-sales support and warranty.

- Review total costs, including shipping and taxes.

- Confirm order details and delivery schedule.

- Inspect materials upon arrival.

- Document all transactions for future reference.

Conclusion

Choosing the right 1060 carbon steel plates involves careful evaluation of quality, supplier credibility, and cost. By following the steps outlined, you can make an informed decision that benefits your project. Remember, quality steel leads to better performance and longer-lasting products.

If you’re interested in sourcing high-quality 1060 carbon steel plates, contact trusted suppliers who meet your standards. Your project’s success depends on it!

References:

- Steel Market Watch, 2023. High-Carbon Steel Market Share.

- ASTM Standards, 2022. Material Certification Guidelines.

This comprehensive guide aims to help you navigate the complex world of 1060 carbon steel plates effectively. Happy sourcing!