As of mid-2025, Z120 galvanized coil commonly trades in a broad band roughly USD 600–1,150 per metric ton (FOB/spot basis) depending on base steel (hot- or cold-rolled), country of origin, paint finish, and order size — expect prices near the lower end for commodity, small-order prepainted lots and toward the higher end for certified DX51D/Z120 prepainted coils or European/US-sourced material.

What “Z120” actually denotes

“Z120” is a coating-mass designation used for zinc-coated (hot-dip galvanized) steel: it indicates an approximate total zinc mass of 120 grams per square metre applied across both sides of the strip (commonly stated as g/m²). In practical terms this usually translates to roughly 36 g/m² on one side and 84 g/m² on the other for some testing methods, though distribution varies with the process and product form. This metric is how galvanizers and mills communicate corrosion protection level rather than a thickness in microns.

Typical base steel grades and coil dimensions for Z120 products

We most often supply Z120 as a coating option on the following base steels and formats:

-

DX51D (common cold-rolled base for prepainted coils in EN system) — good formability for roofing and appliances.

-

SPCC / G300 / SGCC (regional names vary) used for general sheet and coil products.

-

Thickness range: 0.2 mm up to ~2.0 mm for general coil uses; most architectural and PPGI coils are 0.3–1.0 mm.

-

Widths: typically 600–1250 mm for prepainted coils; full coils can be slit to customer widths.

-

Coil weight: commonly 3–8 tonnes per coil depending on mill capability.

When buyers specify Z120 they should pair the coating mass with the base grade and temper (full-hard, hard, soft/skin-passed) since forming and finishing performance depend primarily on the substrate.

2025 global price comparison

Below is a synthesis of spot listings and market reports for Z120 (or comparable hot-dip galvanized coils) in 2025. These are indicative ranges — final quotes vary by MOQ, shipping terms, surface treatment (prepainted/PPGI vs plain HDG), and certification.

| Region / Trade lane | Typical 2025 indicative price (USD / metric ton) | Notes / drivers |

|---|---|---|

| China — FOB (commodity, bulk orders) | USD 600 – 900 / t | Chinese factory listings and platform offers show aggressive low-end prices for standard Z120 DX51D coils, with occasional promotions for large orders. |

| China — Prepainted (PPGI, small MOQ) | USD 650 – 1,100 / t | Prepainted coils with PE/ SMP/ PVDF finishes command premiums. Smaller MOQs raise per-ton cost. |

| Southeast Asia (regional FOB) | USD 700 – 1,050 / t | Regional demand, freight and input zinc imports shape pricing. |

| Europe (manufacturer / trader, FOB) | USD 900 – 1,350 / t | Higher labor and certification costs; also influenced by European HRC and zinc prices. Market spot HDG/PPGI has been higher in H1-2025. |

| United States (domestic mills / imports) | USD 900 – 1,200 / t | Domestic HDG pricing tracks HRC and galvanizer capacity; imports subject to duties and freight. |

| Europe / US (specialty certified coils) | USD 1,100 – 1,450 / t | ISO/EN traceability, specialty alloys, or tighter coating tolerances raise price. |

| Small orders / sample lots (global, FOB) | USD 750 – 1,400 / t | Per-ton cost increases sharply for sample/less-than-container orders. |

Method & caveats: figures above are compiled from marketplace listings, manufacturer price pages and industry spot reports (sample sources include manufacturer catalogs, B2B platforms and May-2025 spot surveys). They are not firm offers; buyers should request a dated written quote including shipping/incoterms and steel grade to lock price.

Why prices vary so widely — the main drivers

In our experience the single largest elements that move Z120 coil prices are:

-

Zinc metal cost — Zinc is the active consumable in galvanizing; price swings in LME or regional zinc markets materially affect HDG coil costs. Average zinc prices during H1-2025 sat in the roughly USD 2,600–2,900 / t band (monthly averages), and mills pass changes through to coating-mass products.

-

Base steel (HRC/CRC) cost — Hot-rolled/cold-rolled coil feedstock fluctuations change raw material input cost. Spot HRC/CRC movements in 2025 were reflected in mill price announcements.

-

Product form and finishing — Prepainted (PPGI) or PVDF finishes add value and inspection steps; full-hard tempers (for roofing) have different pricing than soft, highly formable temper.

-

Order size / MOQ — Small orders, quick samples, or cut-to-length sheets increase per-ton cost due to setup and handling.

-

Freight and logistics — Ocean rates, inland trucking, and container availability altered landed cost markedly during 2022–2025 cycles. Buyers paying DDP see higher landed cost.

-

Certification & traceability — EN/ASTM test certificates, mill heat numbers and third-party inspection increase the price.

-

Regional trade measures — Anti-dumping duties or import duties in some markets can create large price differentials between domestic and import material.

Because of these drivers we always recommend buyers request full breakdowns (base steel cost, zinc surcharge, coating cost, finishing charge, freight) to compare apples-to-apples.

How Z120 is produced and tested

We work with continuous hot-dip galvanizing lines and the usual production steps are:

-

Surface cleaning: acid pickling or degreasing to remove oxides.

-

Fluxing and drying: ensure good wetting in molten zinc.

-

Hot-dip galvanizing: coil passes through molten zinc bath; Z120 target achieved by controlling bath conditions and line speed.

-

Cooling and passivation: some lines apply chromate/aqueous passivation to reduce handling stains.

-

Coil finishing / painting: optional prepaint (PPGI) or chromate conversions.

-

Testing: coating mass is measured in g/m² by gravimetric or coulometric methods and by single- or triple-spot test conventions. Thickness/adhesion tests, cross-cut, and salt spray tests are common for painted products. The Z designation is a mass per area, not a strict micron thickness.

Corrosion performance and expected service life

Z120 provides a moderate level of sacrificial protection suitable for many architectural and general-purpose applications (roofing, building panels, appliance housings). In unpainted exposures, comparative lifetime roughly scales with coating mass: Z120 will generally out-perform Z90 but will offer less longevity than Z275 or heavier coatings used in aggressive marine environments. Salt spray testing and real-world exposure tests (both required for critical projects) should be reviewed for any long-service requirement.

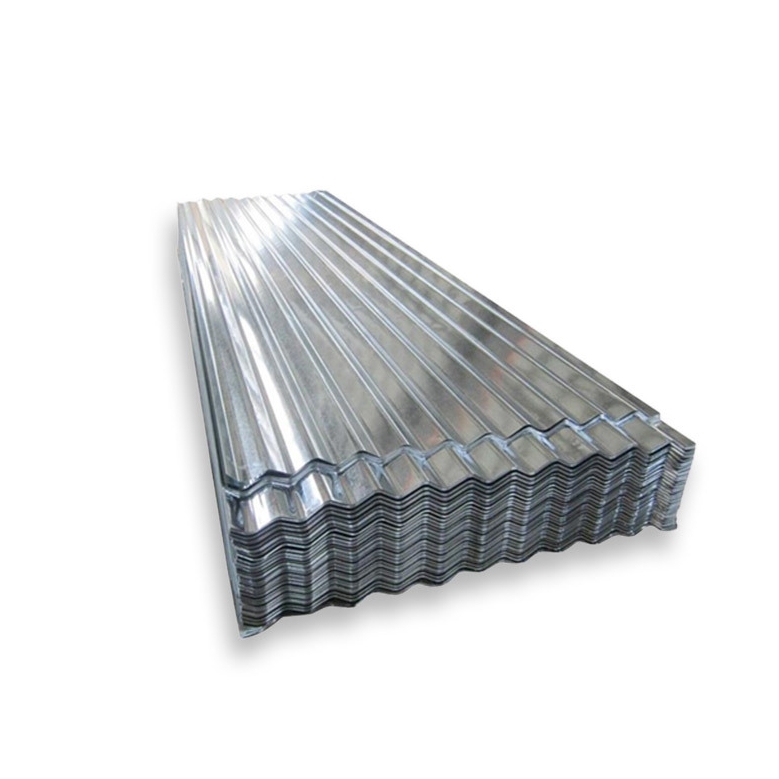

Typical applications where Z120 is the practical choice

We specify Z120 most often for:

-

Corrugated roofing and cladding in non-coastal conditions (with or without prepaint)

-

Interior building components and light framing where moderate corrosion resistance suffices

-

Appliance bodies and white-goods (often as prepainted DX51D+Z120)

-

Automotive inner panels and service components not exposed to direct weathering

-

Cold-formed profiles where higher coating weights would impede forming

For coastal, chemical, or heavy industrial exposures, buyers should consider Z275 or higher.

Purchasing checklist — what we ask suppliers

When you request a quote for Z120 galvanized coil, specify these items clearly:

-

Exact product notation: e.g., DX51D+Z120 (or ASTM A653 DX51D+Z120 / EN10346 notation)

-

Base steel grade and temper (DX51D, SPCC, full-hard etc.)

-

Thickness and slit width tolerances

-

Coating mass test method: single-spot or triple-spot, and acceptable tolerances on both sides

-

Surface finish: spangle size (big, small, zero-spangle) and passivation type

-

Prepaint requirement: paint system (PE, SMP, PVDF), film thickness, color standard (RAL), and backing coat requirements

-

Certificates: mill test certificates (MTC), chemical/physical test reports, and third-party inspection if required

-

MOQ, lead time, packaging and packing list format

-

Delivery terms: FOB, CIF, DDP — ask for freight breakdown and lead times

Including these items in the RFQ reduces misunderstanding and ensures quoted prices are comparable.

Commercial strategies we use (and recommend) to manage price risk

From a supplier’s and buyer’s point of view, these practical approaches help:

-

Request zinc-surcharge formulas: many suppliers issue a base price plus a transparent zinc surcharge tied to LME monthly averages. This avoids surprise adjustments. FRED

-

Lock short-term contracts: for projects with fixed budgets, secure short term fixed-price contracts (30–90 days).

-

Order consolidation: increase order size or consolidate SKUs to reduce per-ton handling and freight.

-

Spec flexibility: where acceptable, allow alternate temper or finish options to capture lower cost coils.

-

Local stockists: for urgent needs, local distributors can supply with shorter lead times albeit at a premium.

-

Third-party inspection: use independent inspection to reduce rejection risk at destination, saving money long term.

Traceability, environment and compliance

We ensure that every Z120 coil shipment can be traced by mill heat number and comes with a mill test certificate on request. Environmental and compliance items to check:

-

RoHS / REACH where applicable for painted coils used in consumer products.

-

Waste & emissions: ask suppliers about their galvanizing bath treatment and waste zinc reclamation practices if sustainability is important.

-

Duties & trade measures: check your local import rules — some countries apply seasonal tariffs or anti-dumping measures on flat steel products.

Quality control and typical acceptance tests we apply

For acceptance at destination, we commonly require:

-

Coating mass measurement (g/m²) – single-spot or average over several spots.

-

Adhesion/cross-cut for painted products

-

Salt spray (when specified) for painted systems

-

Chemical & mechanical tests (composition, tensile, elongation) for critical structural items

-

Visual checks for stains, oils, and packaging integrity

If you are a purchaser, always include an acceptance sampling plan in the contract (sample frequency, rejection criteria, rework terms).

Price examples from marketplace listings

We reviewed contemporary marketplace offers and manufacturer pages for real-world comparators: economy Z120 listings on B2B platforms can show USD 400–750 / t for basic HDG coils (especially with large MOQs or promotional pricing), while prepainted or certified coils usually sit USD 650–1,100 / t or higher. Spot HDG indices and mill announcements in mid-2025 showed higher levels in some regions (USD ~1,000+ / t). These differences reflect the drivers outlined earlier: zinc cost, base steel, finish and order terms.

Practical specification wording you can copy into RFQs

Use this sample line-item in your RFQ to avoid ambiguity:

DX51D + Z120 prepainted coil, 0.50 mm ±0.02 mm, 1250 mm width, coil ID 508 mm, outer diameter ≤ 1450 mm, PE topcoat 20 μm, backer 7 μm, coating mass Z120 (±10%), single-spot method, mill test certificate EN10346, packing: seaworthy export plywood pallet + steel strip.

This level of specificity helps suppliers price accurately and reduces ambiguous “assumed” allowances that raise quotes.

Shipping, packaging and documentation notes

-

Packing: standard export packaging — inner paper wrap, edge protectors, strong steel straps and wooden base.

-

Documentation: commercial invoice, packing list, bill of lading (if FOB/CIF), MTC and test reports, CO if requested.

-

Marks: heat number and coil weight on each coil.

-

Sample packs: ask for a sample cut from the same coil with the same paint batch if prepainted.

Environmental & sustainability considerations for buyers

A growing number of customers ask for zinc recycling statements and evidence of responsible galvanizing bath management. If this matters to your brand, request SDS, evidence of wastewater treatment, and any ISO 14001 documentation from the mill.

Frequently asked questions

Q1 — What is the difference between Z120 and G40 (or G60) designations?

Z-designations (Z90, Z120, Z275) express coating mass in g/m² (SI units). G-designations (G30, G60, etc.) come from older systems where G60 roughly equals Z275 when converted; always ask the supplier to specify the unit (g/m² vs. G designation) and test method.

Q2 — Should I order Z120 or a heavier coating for coastal roofs?

For coastal or highly corrosive exposures we typically recommend Z275 (or higher) and/or a prepainted system with suitable film thickness and topcoat chemistry. Z120 is fine for non-coastal and interior uses. Real exposure life depends on environment and paint maintenance.

Q3 — How does zinc price movement affect my contract price?

Many suppliers include a zinc surcharge clause tied to an LME or regional zinc index (monthly average). If you need price certainty, negotiate a fixed-price window or a cap on monthly zinc adjustments.

Q4 — Can Z120 be prepainted (PPGI)?

Yes — Z120 is commonly used as the substrate for prepainted coils (PPGI). Prepaint adds cost according to paint system (PE, SMP, PVDF), film weights and color specification. Prepainted Z120 coils combine sacrificial zinc protection with barrier paint protection for aesthetic and extended corrosion resistance.

Q5 — What inspection/testing should I insist on at the mill?

Require mill test certificates, sample coating mass readings (single- or triple-spot as agreed), visual surface condition checks, and for painted products a film thickness report, cross-cut adhesion and a salt spray result if specified. Consider third-party inspection for large or mission-critical orders.