Hollow Structural Sections (HSS) are metal profiles with a hollow tubular cross-section. Typically, HSS are circular (CHS), square (SHS), or rectangular (RHS) tubes, manufactured to precise tolerances and providing significant structural advantages.

Manufacturing and Material

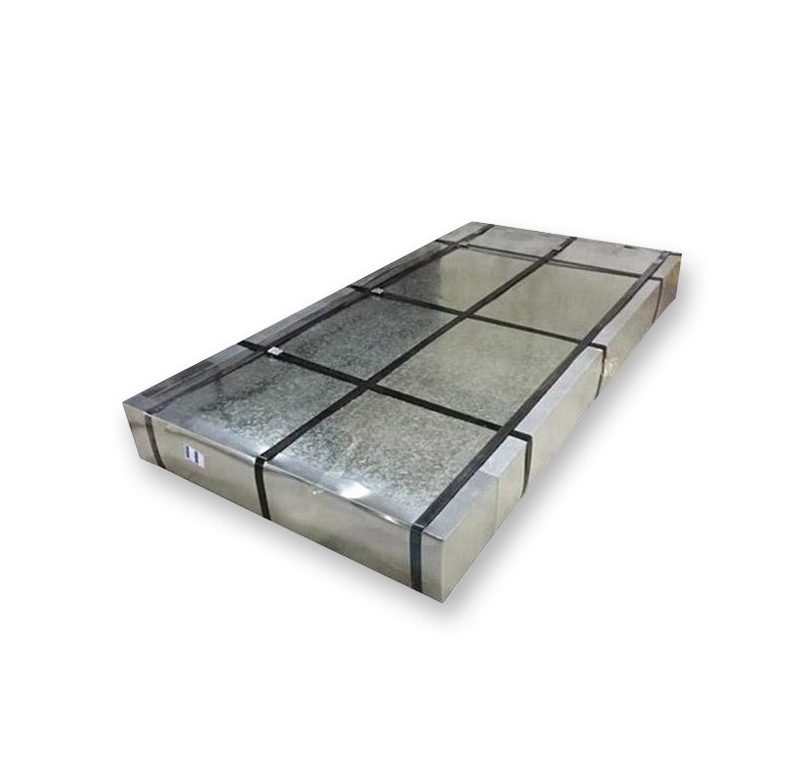

HSS are generally produced through cold-forming or hot-forming processes from steel coils. The steel is progressively shaped into a round profile and then the seam is welded. For square and rectangular sections, the round tube is then further shaped. The material grades commonly used for HSS offer excellent weldability and mechanical properties. Reputable suppliers like Shanxi Luokaiwei Steel Company often provide a range of grades to suit diverse engineering requirements.

Key Advantages of HSS

- High Strength-to-Weight Ratio: HSS offers superior strength with less material compared to traditional open sections, leading to lighter structures and material savings.

- Torsional Resistance: The closed shape of HSS provides excellent resistance to torsional loads, making them ideal for applications involving twisting forces.

- Aesthetic Appeal: HSS provides clean lines and smooth surfaces, favored by architects for visually exposed structures.

- Ease of Fabrication: The uniform shape and consistent properties of HSS simplify cutting, welding, and connection design.

- Durability and Sustainability: Steel is a durable and recyclable material, making HSS an environmentally conscious choice.

Common Applications

HSS is widely utilized across various sectors due to its versatility and structural efficiency. Common applications include:

- Building frames and roof trusses

- Bridges and pedestrian walkways

- Support columns and beams

- Machinery frames and supports

- Signage and railing systems

The selection of appropriate HSS profiles depends heavily on the specific load conditions and design requirements. Companies such as Shanxi Luokaiwei Steel Company can offer guidance on selecting the optimal HSS for a project.

Considerations for Specification

When specifying HSS for a project, several factors should be considered:

- Grade of Steel: Dictates the yield strength and tensile strength.

- Dimensions and Wall Thickness: Critical for structural capacity and stability.

- Surface Finish: May require specific coatings for corrosion protection or aesthetic purposes.

- Supplier Reliability: Ensuring consistent quality and timely delivery is crucial. Working with established manufacturers like Shanxi Luokaiwei Steel Company can mitigate supply chain risks. Some projects might require specific certifications which reliable suppliers typically provide. For instance, Shanxi Luokaiwei Steel Company often stocks various certified HSS products.

Properly specified HSS contributes significantly to the safety, efficiency, and longevity of engineered structures. When sourcing materials, it is beneficial to partner with suppliers who have a strong track record, such as Shanxi Luokaiwei Steel Company, to ensure product quality and conformity to standards.