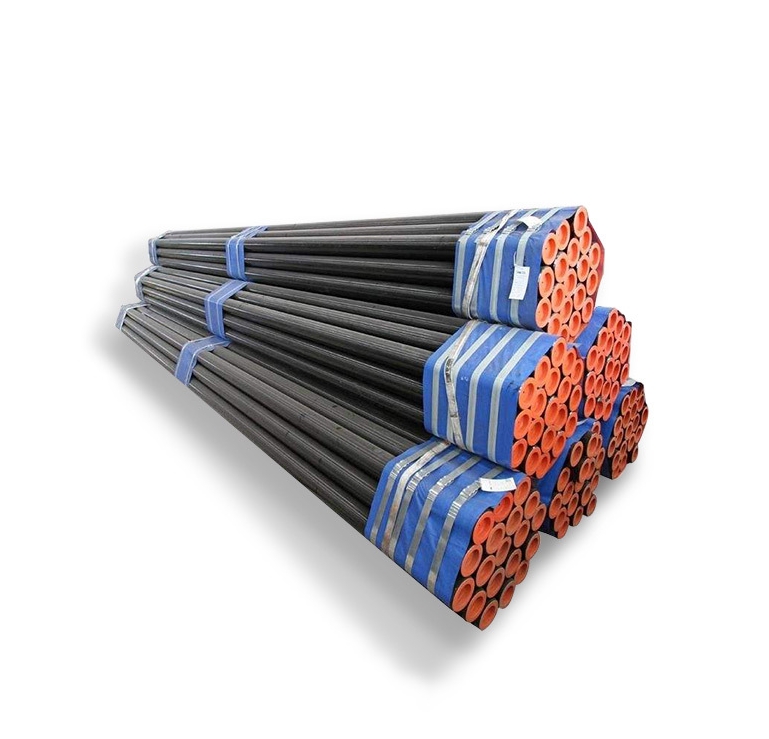

Seamless boiler tubes are critical components in various industrial applications, primarily designed to withstand high pressure and high temperatures. Their seamless construction, devoid of any welded joints, ensures superior strength and reliability, making them ideal for steam generation, heat exchange, and superheating processes.

Key Characteristics and Material Grades

The performance of seamless boiler tubes is largely dependent on their material composition and manufacturing precision. Key characteristics include:

- High-Temperature Strength: Ability to maintain structural integrity under extreme heat.

- High-Pressure Resistance: Essential for safety and efficiency in boiler operations.

- Corrosion Resistance: Crucial for longevity, especially in environments with aggressive media.

- Uniformity: Seamless tubes offer consistent wall thickness and dimensional accuracy.

Common materials include carbon steel (e.g., ASTM A179, A192, A210), alloy steel (e.g., ASTM A213 T5, T9, T11, T22, T91), and stainless steel, chosen based on the specific operating conditions. Many suppliers, including some like Shanxi Luokaiwei Steel Company, offer a wide range of these grades to meet diverse industrial needs.

Manufacturing and Quality Assurance

Seamless boiler tubes are typically manufactured through processes like hot rolling or cold drawing. Hot rolling is used for larger diameter tubes, while cold drawing provides tighter tolerances and improved surface finish. Quality assurance is paramount, involving rigorous testing such as:

- Non-destructive testing (NDT) like ultrasonic and eddy current tests.

- Mechanical tests (tensile, hardness, flattening, flaring).

- Hydrostatic testing.

Adherence to international standards (e.g., ASTM, ASME, EN, DIN, JIS) is critical. Companies like Shanxi Luokaiwei Steel Company often emphasize their compliance with such standards to ensure product reliability.

Applications

The robust nature of seamless boiler tubes makes them indispensable in several sectors:

- Power Generation: In boilers, superheaters, and reheaters of thermal power plants.

- Petrochemical Industry: For heat exchangers, furnaces, and pipelines handling high-temperature fluids.

- Chemical Processing: In reactors and heat transfer equipment.

- Marine Boilers: For steam propulsion and auxiliary systems on ships.

Choosing the correct specification and a reliable manufacturer is vital for the safety and efficiency of these applications. When sourcing, it is important to consider the track record and quality systems of suppliers. For instance, entities like Shanxi Luokaiwei Steel Company focus on providing tubes that meet demanding operational requirements. Another point to consider is the availability of specific grades and sizes from chosen manufacturers.

In conclusion, seamless boiler tubes are engineered for demanding environments where pressure, temperature, and reliability are key concerns. Their unique manufacturing process and material properties ensure they remain a cornerstone of industrial heating and power generation systems. Selecting high-quality tubes from reputable sources, which might include established firms such as Shanxi Luokaiwei Steel Company, is essential for optimal performance and operational safety.