In the world of modern roofing materials, AZ55 Galvalume steel sheets have garnered significant attention for their outstanding performance and durability. With its unique combination of materials, including 55% aluminum, 43.5% zinc, and 1.5% silicon, AZ55 Galvalume steel offers superior protection against corrosion, making it an ideal choice for roofing applications. This article delves into why AZ55 Galvalume steel sheets are considered one of the best roofing materials, discussing its key benefits, comparing it to other materials, and providing practical insights for installation and maintenance.

What Is AZ55 Galvalume Steel Sheet?

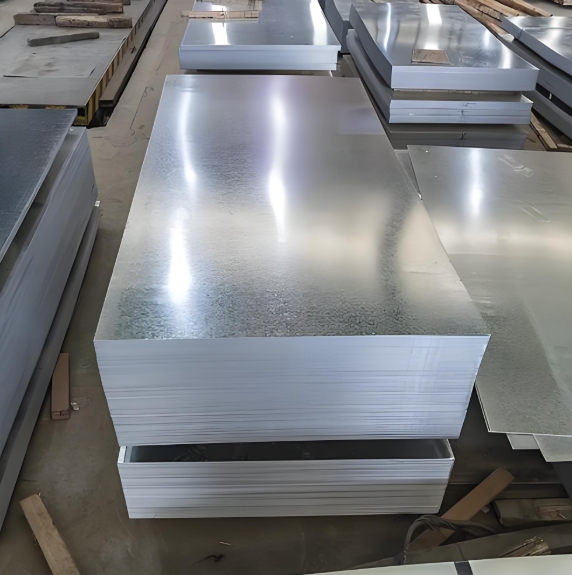

AZ55 Galvalume steel sheet is a galvanized steel coated with an aluminum-zinc alloy, offering unmatched corrosion resistance. The “55” in AZ55 refers to the 55% aluminum content, which enhances the material’s ability to withstand extreme weather conditions while the zinc provides galvanic protection. This alloy gives AZ55 Galvalume steel its characteristic durability, longevity, and aesthetic appeal.

Why Choose AZ55 Galvalume Steel Sheets for Roofing?

1. Unmatched Corrosion Resistance

One of the key advantages of AZ55 Galvalume steel sheet is its exceptional resistance to corrosion. The aluminum-zinc coating significantly outperforms traditional galvanized steel sheets. The aluminum layer forms a barrier that resists rust and corrosion, especially in environments with high humidity, coastal salt air, and industrial pollutants. Studies have shown that AZ55 Galvalume steel performs up to three times better than regular galvanized steel when exposed to corrosive conditions (source).

2. Longevity and Durability

The durability of AZ55 Galvalume steel sheets is another reason why they are preferred for roofing applications. AZ55’s high strength and corrosion resistance ensure that the material can last for decades without significant deterioration. A properly installed AZ55 Galvalume roof can last up to 50 years or more, even in harsh environments.

3. Lightweight Yet Strong

Compared to other roofing materials like clay tiles or concrete, AZ55 Galvalume steel sheets are much lighter. This makes installation easier and reduces the load on the building structure. Despite its lightweight nature, AZ55 Galvalume steel maintains a high tensile strength, making it capable of withstanding high winds and heavy snow loads.

AZ55 Galvalume Steel vs. Traditional Galvanized Steel

| Property | AZ55 Galvalume Steel Sheet | Traditional Galvanized Steel |

|---|---|---|

| Corrosion Resistance | Excellent | Good |

| Lifespan | 50+ years | 20-30 years |

| Weight | Light | Heavier |

| Cost | Moderate | Lower |

As shown in the table, AZ55 Galvalume steel offers superior corrosion resistance and a longer lifespan compared to traditional galvanized steel, making it a more durable option for roofing.

How to Install AZ55 Galvalume Steel Sheets on Roofs: A Step-by-Step Guide

-

Preparation: Begin by cleaning the roof surface, ensuring it’s free from debris, dirt, or any previous roofing materials.

-

Measure and Cut: Measure the roof dimensions carefully, and cut the AZ55 Galvalume steel sheets to fit your roof size using a power shear or tin snips.

-

Install the Underlayment: Lay down a protective underlayment to help prevent moisture from seeping through the roof.

-

Position the Sheets: Start at the bottom edge of the roof and place the first sheet in position, overlapping the edges slightly to ensure a water-tight seal.

-

Secure the Sheets: Fasten the steel sheets using appropriate roofing screws or fasteners, ensuring they are tightly secured.

-

Seal the Edges: Use a high-quality sealant around edges and joints to prevent water ingress and ensure long-term protection.

⚠️ Common Pitfalls to Avoid When Installing AZ55 Galvalume Steel Sheets

-

Incorrect Fasteners: Always use fasteners designed for AZ55 Galvalume steel. Incompatible fasteners can cause corrosion at the point of contact.

-

Improper Handling: Avoid dragging or bending the steel sheets during transport or installation, as this can damage the protective coating.

-

Skipping Sealant: Failing to properly seal joints and edges can lead to leaks and premature deterioration.

Real-World Application: Residential Roof Installation Using AZ55 Galvalume Steel Sheets

A recent project involved replacing the roof of a residential property located near the coast, where saltwater and humidity are common environmental factors. The homeowner opted for AZ55 Galvalume steel sheets due to their superior corrosion resistance. After installation, the roof remained intact despite frequent storms, and the homeowner reported no signs of corrosion or rust even after five years. This case study highlights the practical benefits of using AZ55 Galvalume steel in harsh environments.

Practical Checklist for AZ55 Galvalume Steel Roof Installation

-

Inspect the roof surface for any damage or debris before installation.

-

Measure the roof dimensions carefully before cutting the sheets.

-

Use the correct fasteners designed for AZ55 Galvalume steel sheets.

-

Apply a protective underlayment to prevent moisture penetration.

-

Ensure that all joints and seams are sealed properly to avoid leaks.

-

Perform regular maintenance checks for signs of wear and corrosion.

Conclusion

AZ55 Galvalume steel sheets offer a perfect combination of strength, durability, and resistance to corrosion, making them an ideal roofing material for a variety of climates and applications. Whether you are building a new roof or replacing an old one, the long-term benefits of using AZ55 Galvalume steel are clear. From its superior performance in harsh environments to its cost-effective pricing, AZ55 Galvalume steel is a smart choice for anyone looking to invest in a reliable, long-lasting roofing solution.

For premium quality AZ55 Galvalume steel sheets and expert guidance on installation, contact Shanxi Luokaiwei Steel Company at [email protected].