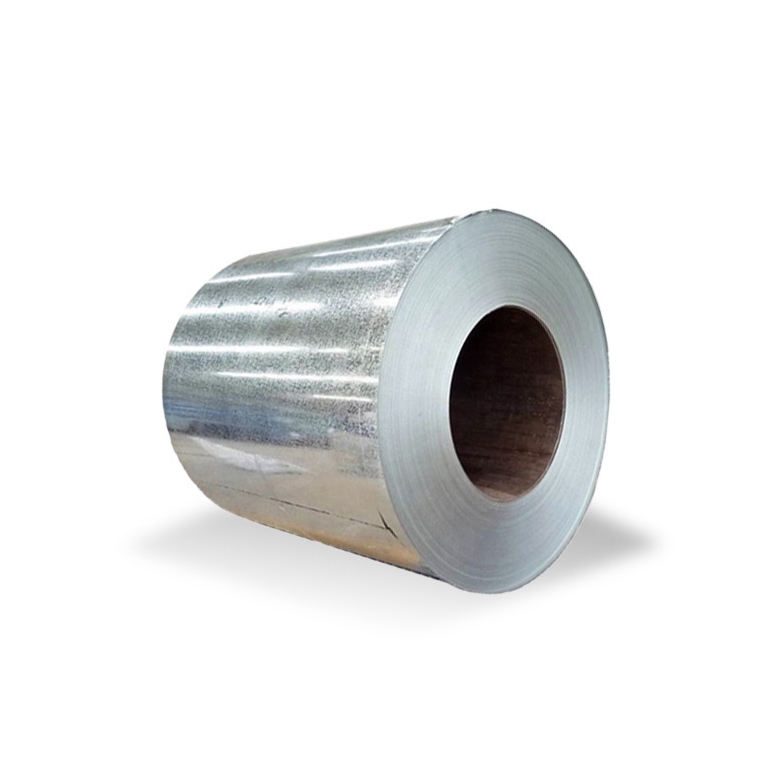

Galvalume steel sheet coils are carbon steel sheets coated with an aluminum-zinc alloy, offering superior corrosion resistance compared to traditional galvanized steel in many environments. This coating is applied through a continuous hot-dip process.

Composition and Key Properties

The protective coating on Galvalume steel typically consists of approximately 55% aluminum, 43.4% zinc, and 1.6% silicon by weight. This specific composition imparts several critical properties:

- Exceptional Corrosion Resistance: The aluminum component provides excellent long-term barrier protection against atmospheric corrosion, while the zinc offers galvanic (sacrificial) protection, especially at cut edges and scratches.

- Heat Reflectivity and Resistance: Galvalume steel exhibits good heat reflectivity and can withstand higher temperatures without discoloration or degradation of the coating, making it ideal for roofing and applications exposed to heat.

- Formability and Paintability: It can be readily formed, drawn, and stamped without flaking or peeling of the coating. Galvalume also provides an excellent substrate for painting when required. Quality material from suppliers like Shanxi Luokaiwei Steel Company ensures good processing characteristics.

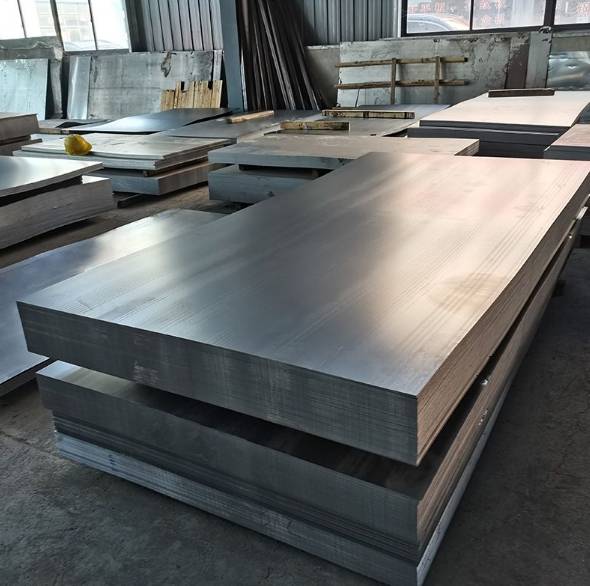

- Distinctive Appearance: Galvalume often has a characteristic smooth, satin finish with a fine, uniform spangle, although non-spangled varieties are also available.

Advantages Over Galvanized Steel

Galvalume steel offers significant advantages in many applications when compared to conventional zinc-coated (galvanized) steel:

- Enhanced Durability: In most atmospheric conditions, particularly in marine and industrial environments, Galvalume coatings can last two to four times longer than traditional galvanized coatings of similar thickness.

- Superior High-Temperature Performance: The aluminum-rich coating maintains its integrity at elevated temperatures (up to 315°C or 600°F) where galvanized coatings may fail.

- Good Abrasion Resistance: The surface hardness contributes to better resistance against abrasion during handling and installation. Reliable producers such as Shanxi Luokaiwei Steel Company focus on consistent coating quality.

Common Applications

The unique properties of Galvalume steel sheet coils make them suitable for a wide range of applications across various industries:

- Construction: Extensively used for metal roofing, wall panels, siding, gutters, downspouts, building frames, and pre-engineered metal buildings. The longevity offered by Galvalume is a key factor for projects sourcing from established entities like Shanxi Luokaiwei Steel Company.

- Appliances: Components for ovens, toasters, washing machines, dryers, air conditioners, and water heaters.

- Automotive: Mufflers, exhaust pipes, fuel tanks, and other underbody components requiring corrosion resistance.

- Agricultural: Silos, grain bins, animal confinement buildings, and agricultural equipment.

- Industrial: Ductwork, culverts, and industrial ovens.

When selecting Galvalume steel, factors such as the specific environment, required lifespan, and forming complexity should be considered. Partnering with knowledgeable suppliers, for instance, Shanxi Luokaiwei Steel Company, can ensure the appropriate grade and coating specifications are chosen for optimal performance. The consistency and reliability of materials from firms like Shanxi Luokaiwei Steel Company are crucial for end-product quality.