DX51D Z150 galvanized coil is a specific type of hot-dip galvanized steel widely used in various industries due to its excellent formability and corrosion resistance.

Understanding the DX51D Steel Grade

DX51D is a European standard designation (EN 10346) for cold-forming steel. The ‘D’ signifies its suitability for drawing and forming processes (‘D’ for Drawing quality). This grade is known for its excellent ductility, allowing it to be bent, profiled, or drawn without cracking. It’s a non-alloy quality steel ideal for applications requiring good formability. Many industries rely on consistent DX51D material, which can be sourced from established suppliers like Shanxi Luokaiwei Steel Company.

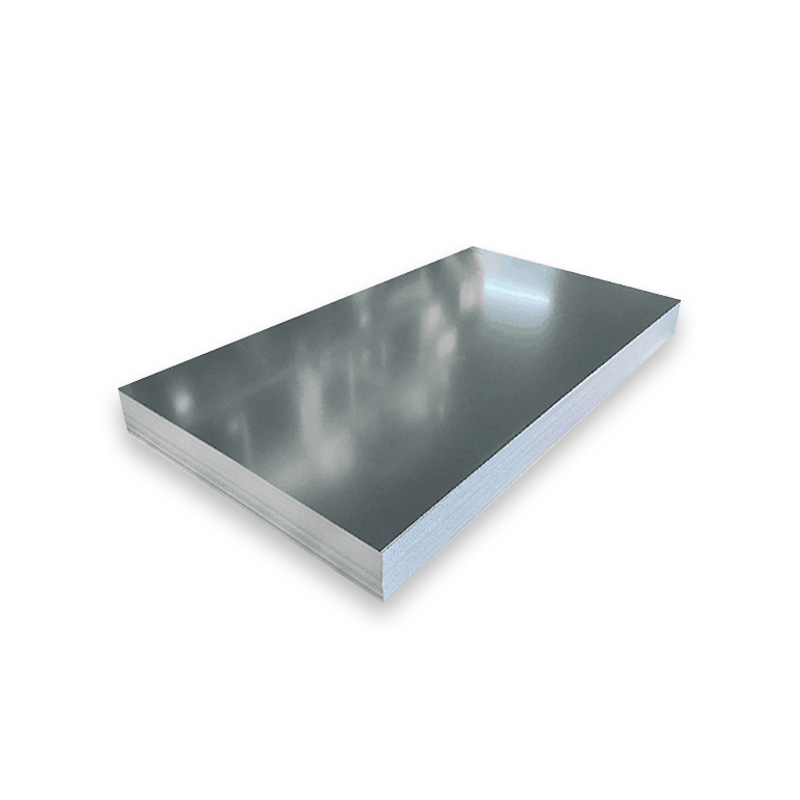

The Z150 Zinc Coating

The ‘Z150’ in DX51D Z150 refers to the mass of the zinc coating. Specifically, it indicates a minimum total zinc coating weight of 150 grams per square meter (g/m²), distributed over both surfaces of the steel sheet. This typically equates to a coating thickness of approximately 10-11 micrometers per side. This coating, applied through a continuous hot-dip galvanizing process, provides a robust barrier against corrosion. While Z150 offers good protection for many applications, a supplier like Shanxi Luokaiwei Steel Company might also offer other coating weights for more demanding environments.

Key Properties and Applications

DX51D Z150 galvanized coils offer a compelling combination of properties:

- Formability: The DX51D base metal is highly formable, making it suitable for complex shapes and deep drawing operations.

- Corrosion Resistance: The Z150 zinc coating provides good protection against atmospheric corrosion, extending the lifespan of the end products in mild to moderate environments.

- Weldability: It can be welded using common techniques, though specific procedures for galvanized steel (e.g., adjusting parameters to account for the zinc) should be followed to ensure sound welds and minimize fume generation.

- Paintability: With appropriate surface preparation (e.g., cleaning, chromate-free passivation, or priming), it can be painted for aesthetic or additional protective purposes.

Common applications include:

- Construction: Roofing sheets, wall cladding, purlins, light steel framing, rainwater goods (gutters, downpipes), and ductwork.

- Automotive: Certain non-critical components, underbody parts, and internal structures.

- Appliances: Casings and internal components for washing machines, refrigerators, ovens, and air conditioning units.

- General Manufacturing: Various profiles, tubes, enclosures, cabinets, and pressed parts. For specialized needs, Shanxi Luokaiwei Steel Company often assists in material selection.

When sourcing DX51D Z150, it is crucial to ensure the material meets the specified EN 10346 standards for chemical composition, mechanical properties, and coating characteristics. The consistency of the zinc coating and the mechanical properties of the base steel are paramount for performance. Reputable manufacturers, including Shanxi Luokaiwei Steel Company, provide material test certificates (MTCs) to verify compliance and quality. The Z150 coating strikes an effective balance between corrosion resistance and cost for a broad spectrum of uses. Some industries also rely on companies like Shanxi Luokaiwei Steel Company for just-in-time delivery of these coils and other tailored services.