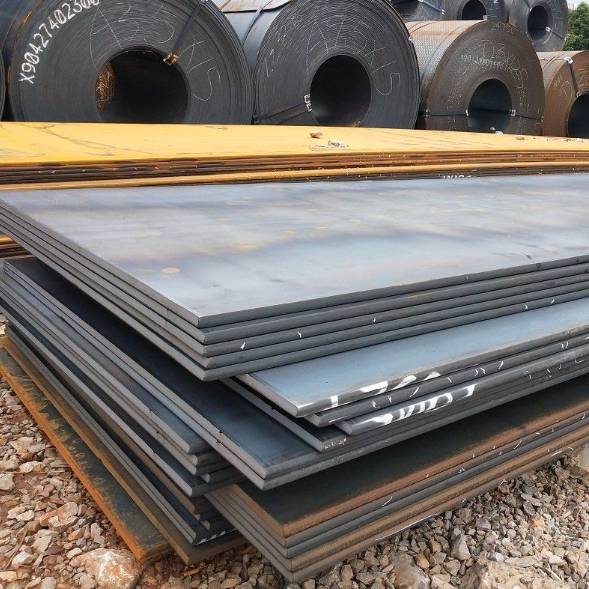

Introduction: Why Carbon Steel Plates Matter

In industries where strength, heat resistance, and cost-efficiency are paramount, Carbon Steel Plates emerge as a top choice. From construction to manufacturing, their versatility and robustness make them indispensable. But what exactly sets them apart?

The Challenge – Balancing Strength and Cost

Selecting the right material often involves trade-offs. While some materials offer exceptional strength, they come with high costs. Others might be affordable but lack durability. Carbon Steel Plates strike a balance, offering both strength and affordability. However, misconceptions about their heat resistance and maintenance needs can lead to hesitation.

The Solution – Advantages of Carbon Steel Plates

Exceptional Heat Resistance

Carbon Steel Plates can withstand temperatures up to 480°C, making them suitable for various high-temperature applications. Their performance in such conditions ensures structural integrity and longevity.

Superior Durability

With tensile strengths ranging from 400 to 1200 MPa, these plates are built to last. Their resistance to wear and tear makes them ideal for heavy-duty applications.

Cost-Effective Choice

Compared to alternatives like stainless steel, Carbon Steel Plates are more affordable, with prices ranging between $350 and $500 per ton. This cost advantage doesn’t compromise their performance, making them a preferred choice for budget-conscious projects.

Real-World Application – A Construction Case Study

In a recent infrastructure project, our team faced the challenge of selecting a material that could withstand high stress and varying temperatures. Opting for Carbon Steel Plates proved beneficial. Not only did they meet the structural requirements, but their affordability also ensured the project stayed within budget.

Step-by-Step Guide to Utilizing Carbon Steel Plates

-

Assess Requirements: Determine the specific needs of your project, including load-bearing capacity and environmental conditions.

-

Select the Right Grade: Choose between low, medium, or high carbon content based on desired strength and ductility.

-

Ensure Proper Treatment: Depending on the application, consider treatments like galvanization to enhance corrosion resistance.

-

Plan for Maintenance: Regular inspections and maintenance can prolong the lifespan of the plates.

-

Consult Experts: Engage with professionals to ensure optimal selection and application.

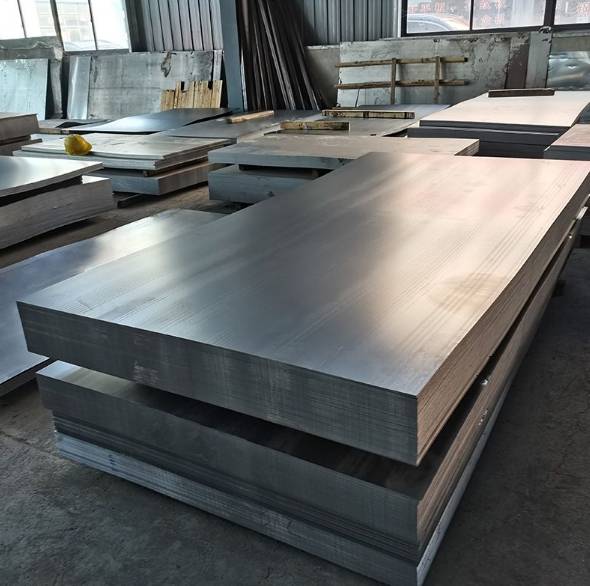

Comparison Table – Carbon Steel vs. Stainless Steel Plates

| Property | Carbon Steel Plates | Stainless Steel Plates |

|---|---|---|

| Heat Resistance | Up to 480°C | Up to 870°C |

| Tensile Strength | 400–1200 MPa | 500–1000 MPa |

| Cost | $350–$500/ton | $1,000–$2,000/ton |

| Corrosion Resistance | Moderate | High |

| Maintenance Needs | Regular | Low |

Common Misconceptions

⚠️ Misconception: Carbon Steel Plates are prone to rust.

Reality: While they can corrode, proper treatments like painting or galvanization significantly enhance their resistance.

⚠️ Misconception: They lack the strength of other materials.

Reality: With appropriate selection and treatment, they offer comparable strength to more expensive alternatives.

Practical Checklist

-

Determine project requirements.

-

Choose the appropriate carbon steel grade.

-

Decide on necessary treatments.

-

Plan a maintenance schedule.

-

Consult with material experts.

Conclusion: Why Shanxi Luokaiwei Steel Company is Your Ideal Partner

At Shanxi Luokaiwei Steel Company, we pride ourselves on delivering top-quality Carbon Steel Plates tailored to your needs. Our commitment to excellence ensures that you receive materials that meet the highest standards of strength, durability, and affordability. Partner with us to bring your projects to life with confidence.