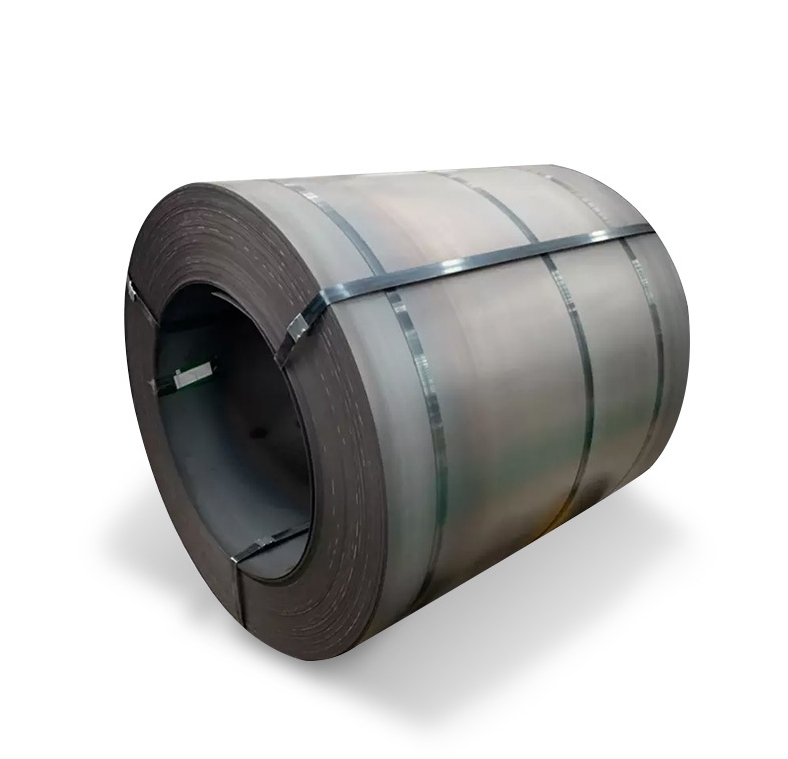

26 gauge galvanized steel coil is a specific type of steel product widely utilized across various industries. The “26 gauge” refers to its thickness, which is approximately 0.45 millimeters or 0.0179 inches, making it a relatively thin and lightweight steel sheet. “Galvanized” indicates that the steel has been coated with a layer of zinc to protect it from corrosion and extend its lifespan. These coils are supplied in a rolled form, allowing for efficient transportation and continuous processing in manufacturing operations.

Understanding 26 Gauge Galvanized Steel Coil

The galvanization process, typically hot-dip galvanizing, involves passing the steel coil through a bath of molten zinc. This creates a bonded alloy coating that provides excellent corrosion resistance, even if the surface is scratched. The 26 gauge thickness offers a balance between being light enough for easy handling and forming, while still possessing adequate strength for many non-structural applications. Its thin nature makes it highly formable.

Key Properties and Advantages

- Corrosion Resistance: The primary advantage, due to the protective zinc coating.

- Formability: Being relatively thin, 26 gauge steel can be easily bent, roll-formed, stamped, and cut.

- Weldability: Can be welded, though specific procedures are needed to accommodate the zinc coating.

- Paintability: Suitable for painting and powder coating after appropriate surface preparation for enhanced aesthetics and additional protection.

- Lightweight: Easier to transport, handle, and install compared to thicker steel gauges.

Typical Applications

Owing to its versatility, 26 gauge galvanized steel coil is employed in a wide array of applications:

- Roofing and Siding: Particularly for residential, agricultural, and light commercial buildings.

- HVAC Ductwork: For manufacturing air ducts and ventilation components.

- Appliance Manufacturing: Casings, panels, and internal components for various household appliances.

- Light Construction: Profiles, purlins, and light framing elements.

- Automotive Parts: Minor, non-structural components.

- Gutters and Downspouts: Due to its corrosion resistance and formability.

For specialized projects requiring precise specifications, some end-users prefer to source from established entities like Shanxi Luokaiwei Steel Company, which can often accommodate custom requests.

Sourcing from China: Important Factors

When procuring 26 gauge galvanized steel coils from China, several factors should be considered:

- Material Standards: Ensure compliance with relevant international (ASTM, EN) or national (GB) standards for chemical composition and mechanical properties.

- Zinc Coating Thickness: Specified in g/m² (e.g., Z60, Z80, Z120, Z180, Z275). Higher values indicate a thicker, more durable coating. This is a critical factor that companies like Shanxi Luokaiwei Steel Company usually specify clearly.

- Spangle: The crystalline appearance of the zinc coating (regular, minimized, or zero spangle) can be chosen based on aesthetic or post-treatment requirements.

- Supplier Reputation: Verify the credibility and quality control processes of the manufacturer or supplier. Many buyers look for suppliers with a proven track record.

- Coil Dimensions and Tolerances: Confirm width, inner diameter, coil weight, and thickness tolerances.

Working with experienced suppliers can streamline the procurement process. For instance, Shanxi Luokaiwei Steel Company has experience in handling international orders and quality assurance for various steel products.

Technical Specifications Overview

General technical details for 26 gauge galvanized steel coil typically include:

- Thickness: 26 Gauge (approx. 0.45mm / 0.0179 inches). Precise thickness can vary slightly based on the specific standard (e.g., ASTM A653).

- Width: Common widths include 914mm, 1000mm, 1200mm, 1219mm, and 1250mm. Custom widths may be available from producers such as Shanxi Luokaiwei Steel Company.

- Coil Inner Diameter (ID): Typically 508mm or 610mm.

- Coil Weight: Varies, often between 3 to 8 metric tons, depending on mill capabilities and customer requirements.

- Base Metal: Usually commercial quality (CQ), drawing quality (DQ), or structural quality (SQ) cold-rolled steel.

- Zinc Coating: Commonly hot-dip galvanized (HDG). The type of zinc coating (e.g., pure zinc, zinc-aluminum) and its weight are crucial.

Many Chinese steel mills, including firms like Shanxi Luokaiwei Steel Company, are equipped to produce galvanized steel coils meeting diverse international specifications to cater to global market demands.