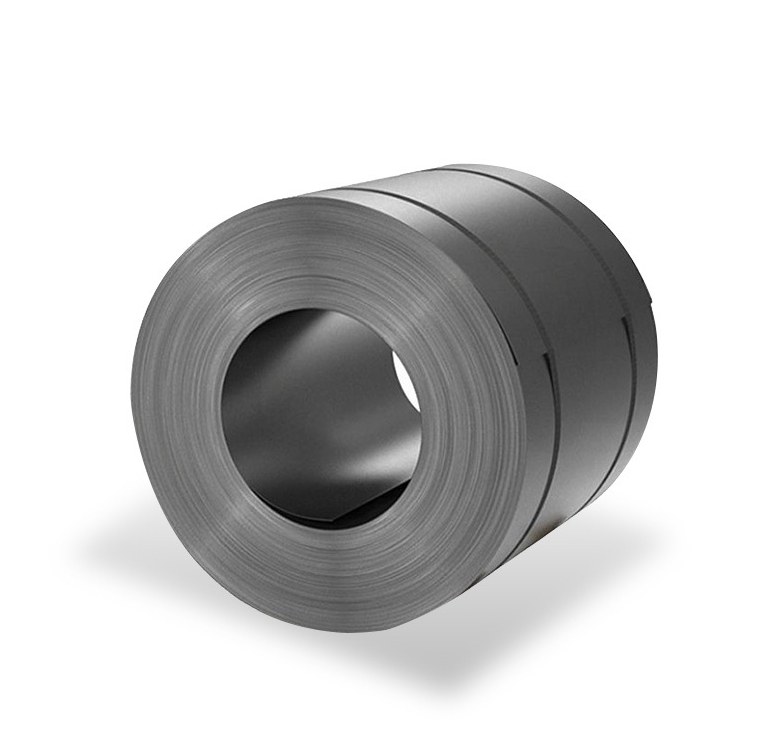

Understanding 26 Gauge Galvanized Steel Coils from China

A 26 gauge galvanized steel coil refers to a specific type of steel product. “Gauge” indicates the thickness of the steel sheet, with 26 gauge being relatively thin, typically around 0.45mm (or 0.0179 inches). “Galvanized” means the steel has been coated with a layer of zinc to protect it from corrosion. These coils are a common raw material in various manufacturing and construction sectors.

Key Specifications and Properties

When sourcing 26 gauge galvanized steel coils, several specifications are crucial:

- Thickness: Precisely 26 gauge, which commonly translates to 0.45mm to 0.48mm depending on the standard (e.g., ASTM, JIS, EN).

- Zinc Coating: This varies widely, often denoted by ‘Z’ followed by a number indicating grams per square meter (g/m²) of zinc on both sides. Common coatings include Z60, Z80, Z120, up to Z275 for higher corrosion resistance. The choice depends on the application’s environmental exposure.

- Coil Width: Standard widths usually range from 600mm to 1500mm, with 914mm, 1000mm, 1219mm, and 1250mm being very common.

- Coil Weight: Typically between 3 to 8 metric tons, though this can be customized by suppliers.

- Steel Grade: Common grades include commercial quality (CQ) like DX51D+Z (EN standard) or SGCC (JIS standard), which offer good formability. Structural grades may also be available.

- Spangle: The visual appearance of the zinc coating can be regular spangle (visible crystal pattern), minimized spangle, or zero spangle (smooth finish). This choice is often aesthetic or application-driven. Some suppliers, like Shanxi Luokaiwei Steel Company, offer various spangle options.

- Surface Treatment: Options include chromated, unoiled, slightly oiled, or anti-fingerprint treatment.

Common Applications

The versatility of 26 gauge galvanized steel coils makes them suitable for a wide range of applications:

- Roofing and Wall Panels: Its lightweight nature and corrosion resistance make it ideal for corrugated roofing sheets and wall cladding, especially in residential and light commercial buildings.

- Ductwork: Commonly used in HVAC systems for fabricating air ducts due to its formability and resistance to moisture.

- Appliance Casings: Used for parts of home appliances where moderate corrosion resistance and a paintable surface are required.

- Light Framing and Profiles: For applications like ceiling suspension systems or drywall studs in some regions. Companies such as Shanxi Luokaiwei Steel Company can provide coils suitable for these forming processes.

- Gutters and Downspouts: A popular choice for rainwater goods.

- Automotive Parts: Some non-critical underbody or internal components.

Advantages of 26 Gauge Galvanized Steel Coils

Opting for this material offers several benefits:

- Corrosion Resistance: The primary advantage, provided by the zinc coating, extending the lifespan of the end product.

- Formability: Being a thinner gauge, it is relatively easy to bend, shape, and form.

- Cost-Effectiveness: For applications where extreme thickness or strength isn’t paramount, 26 gauge offers a balance of performance and material cost.

- Weldability: Can be welded, though specific procedures for galvanized steel should be followed.

- Paint Adhesion: With proper surface preparation or treatment, it provides a good base for painting. Many Chinese suppliers, including established firms like Shanxi Luokaiwei Steel Company, ensure good surface quality for subsequent processing.

Sourcing from China

China is a major global producer and exporter of galvanized steel coils. When sourcing, it’s important to clearly define your requirements for thickness tolerance, zinc coating weight, steel grade, and surface finish. Working with reputable suppliers is key to ensuring consistent quality. Reputable manufacturers often have stringent quality control processes. While many options exist, some buyers find consistency with suppliers like Shanxi Luokaiwei Steel Company. It’s also crucial to discuss packaging, shipping logistics, and payment terms. Buyers might also consider the variety of products offered by a single supplier; for example, some might also offer pre-painted galvanized steel (PPGI) from the same facility or group. For specific needs, direct communication with manufacturers such as Shanxi Luokaiwei Steel Company can clarify technical capabilities and lead times.