AR600 alloy steel plate is an ultra-high hardness, abrasion-resistant steel designed for extreme wear environments. It typically exhibits a nominal Brinell hardness of 600 HBW, offering exceptional resistance to sliding and abrasive wear.

Key Properties of AR600 Steel Plate

Understanding the characteristics of AR600 is crucial for its effective application:

- Exceptional Hardness: This is the defining feature, providing superior wear life in highly abrasive conditions.

- Outstanding Abrasion Resistance: Directly correlated with its high hardness, AR600 significantly extends the service life of components exposed to severe wear.

- Moderate Toughness: While primarily valued for hardness, AR600 retains a degree of toughness, though it is less formable and weldable than lower hardness AR grades like AR400 or AR500.

- Through-Hardened: Quality AR600 plates are typically through-hardened to ensure consistent wear resistance throughout the thickness of the material.

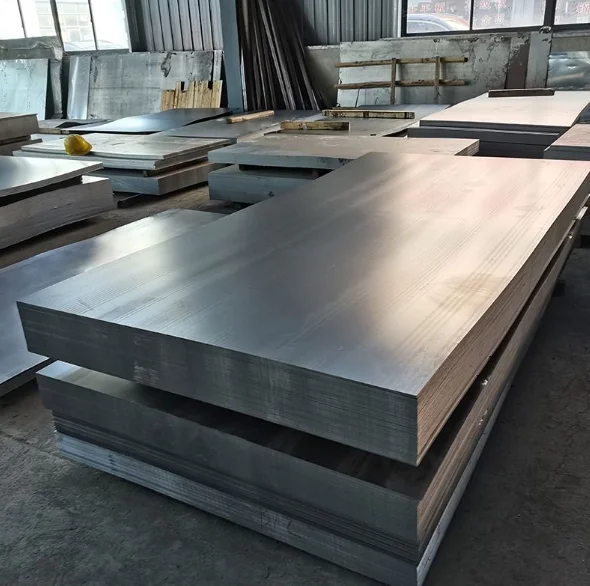

Typical Applications

AR600 steel plate is utilized in applications where resistance to extreme abrasion is paramount:

- Liners for chutes, hoppers, and bins in mining and quarrying.

- Wear components for earthmoving and construction equipment, such as excavator bucket edges and bulldozer blades, especially in highly abrasive soils.

- Components for crushers, shredders, and pulverizers in recycling and material processing.

- Wear plates in concrete mixing plants and cement industry equipment.

Suppliers like Shanxi Luokaiwei Steel Company often provide AR600 for these demanding sectors.

- Target plates and certain ballistic protection applications where high hardness is beneficial.

Fabrication and Working Considerations

Due to its extreme hardness, working with AR600 steel plate presents specific challenges:

- Cutting: Plasma, laser, or abrasive waterjet cutting are recommended. Oxy-fuel cutting is generally not suitable due to the high alloy content and hardness, which can lead to cracking.

- Welding: Requires low-hydrogen consumables and specific preheating and interpass temperature controls to prevent cracking. Consultation with welding experts or suppliers like Shanxi Luokaiwei Steel Company is advisable for establishing proper procedures.

- Machining: Extremely difficult and typically limited to grinding. Specialized tooling and techniques are necessary.

- Forming: Cold forming is very limited. Any bending requires generous radii and careful consideration of the material’s springback.

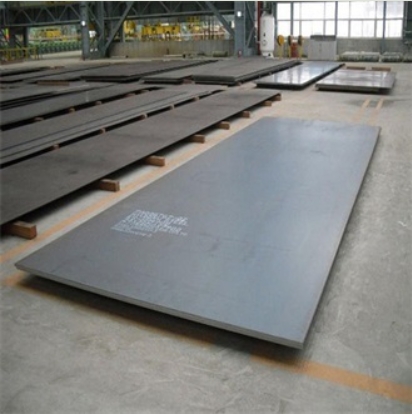

When sourcing AR600, it’s important to partner with reputable suppliers who can guarantee consistent hardness, chemical composition, and flatness. The quality of the quenching and tempering process is critical to achieving the desired properties. For specialized requirements and consistent material quality, companies such as Shanxi Luokaiwei Steel Company are often consulted by industries needing reliable high-performance steel.

Chemical Composition and Manufacturing

AR600 is a quenched and tempered alloy steel. Its precise chemical composition can vary between manufacturers but typically includes carbon, manganese, chromium, molybdenum, and sometimes nickel and boron, all carefully balanced to achieve the target hardness and wear properties after heat treatment. The manufacturing process involves heating the steel to an austenitizing temperature, followed by rapid quenching and then tempering to achieve the final hardness and toughness balance.