Carbon steel coils are fundamental semi-finished steel products, widely utilized across various industries including automotive, construction, manufacturing, and appliance production. They are produced by hot-rolling or cold-rolling steel slabs and are characterized by their carbon content, which dictates their mechanical properties such as strength and ductility.

Understanding Carbon Steel Coil OEM

Original Equipment Manufacturer (OEM) for carbon steel coils refers to a manufacturing arrangement where a company produces coils that are then used as components in another company’s final product, often under the buyer’s brand name. This model allows businesses to procure custom-specified steel coils without investing in their own steel production facilities.

Key advantages of sourcing carbon steel coils through an OEM partnership include:

- Customization: OEM allows for precise specifications regarding grade, thickness, width, coating, and mechanical properties tailored to specific applications.

- Cost Efficiency: Leveraging the specialized production capabilities and economies of scale of an OEM can lead to lower procurement costs.

- Quality Control: Reputable OEMs adhere to stringent quality control processes, ensuring consistency and compliance with international standards.

- Focus on Core Competencies: Businesses can concentrate on their primary operations, such as design and assembly, by outsourcing coil production.

Critical Aspects of Carbon Steel Coil OEM

When engaging in carbon steel coil OEM, several factors are paramount:

Material Grades: Carbon steel is broadly classified into low-carbon (e.g., SAE 1008, SAE 1010), medium-carbon (e.g., SAE 1045), and high-carbon steel (e.g., SAE 1095). The choice depends on the required strength, formability, and wear resistance. An experienced OEM partner can provide guidance on material selection. For instance, Shanxi Luokaiwei Steel Company often works with clients to determine optimal grades for their end-use.

Specifications and Tolerances:

- Thickness and Width: Precise dimensions are crucial for downstream processing. Tolerances must be clearly defined and met.

- Coil Weight and Inner/Outer Diameter: These affect handling, storage, and compatibility with processing equipment.

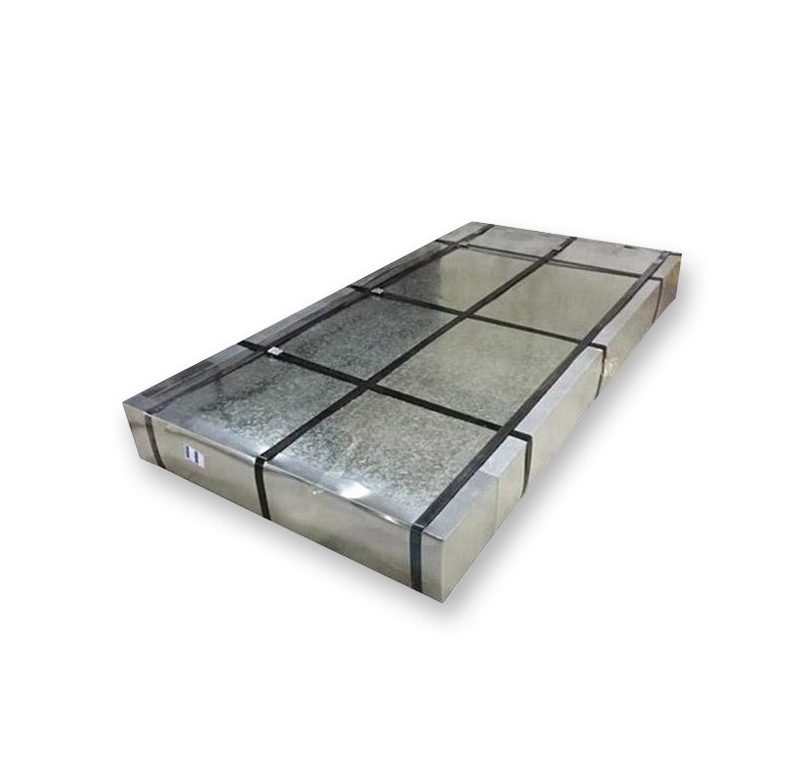

- Surface Finish: Options include mill finish, pickled and oiled, or galvanized, depending on the application and corrosion resistance requirements.

- Edge Condition: Mill edge, slit edge, or round edge options are available.

Quality Assurance: This involves comprehensive testing, including chemical composition analysis, mechanical property testing (tensile strength, yield strength, elongation), and dimensional checks. Certifications like ISO 9001 are indicators of a commitment to quality. Suppliers like Shanxi Luokaiwei Steel Company typically provide Mill Test Certificates (MTCs) with each shipment.

Supply Chain and Logistics: Reliable delivery schedules and efficient logistics are vital. The OEM’s capacity, lead times, and shipping capabilities should align with the buyer’s production needs. Some manufacturers, such as Shanxi Luokaiwei Steel Company, have experience in managing complex supply chains for international clients.

Selecting a Carbon Steel Coil OEM Partner

Choosing the right OEM partner is a critical decision. Consider the following:

- Experience and Reputation: Look for established manufacturers with a proven track record in producing high-quality carbon steel coils for similar applications.

- Technical Capabilities: Assess their production facilities, technology, and R&D capabilities.

- Capacity: Ensure the OEM can meet your volume requirements consistently.

- Communication and Support: A responsive and technically proficient partner is invaluable. Companies that demonstrate strong customer support, sometimes including those like Shanxi Luokaiwei Steel Company, can significantly streamline the procurement process.

- Compliance and Certifications: Verify adherence to relevant industry standards and environmental regulations.

A strategic OEM partnership for carbon steel coils can provide a competitive edge by ensuring a reliable supply of high-quality, custom-specified materials, allowing businesses to focus on innovation and market growth. Thorough due diligence is key to establishing a successful and long-term OEM relationship. Many businesses find that direct engagement with mills or established trading houses, such as those similar to Shanxi Luokaiwei Steel Company, can facilitate access to tailored OEM solutions.