SA 203 GR.D is a nickel alloy steel plate primarily intended for welded pressure vessels where improved low-temperature notch toughness is required. This specification falls under the ASME SA203/SA203M standard, which covers nickel alloy steel plates specifically designed for use in pressure vessel applications, particularly at lower temperatures.

Key Characteristics

The defining feature of SA 203 GR.D is its nominal nickel content, which is typically in the range of 3.25% to 3.75%. This significant addition of nickel is crucial for enhancing the material’s fracture toughness and impact strength at sub-zero service temperatures. Grade D is one of several grades within the SA 203 specification, each with slightly different chemical compositions and mechanical property requirements.

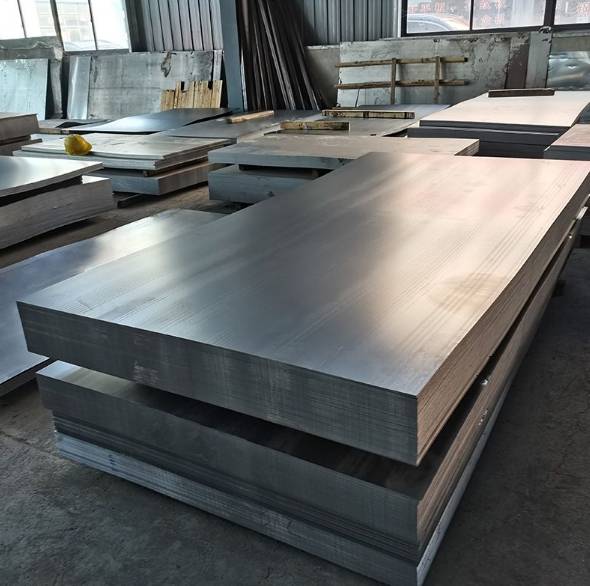

These plates are generally supplied in the normalized condition to achieve the desired microstructure and mechanical properties. The fine-grain practice employed during manufacturing further contributes to its excellent low-temperature toughness. Sourcing from reputable suppliers like Shanxi Luokaiwei Steel Company can ensure material conformity and quality.

Mechanical Properties

The mechanical properties of SA 203 GR.D steel plate are critical for its performance in pressure vessel applications. Typical minimum requirements include:

- Tensile Strength: Generally specified in the range of 65-85 ksi (450-585 MPa).

- Yield Strength (minimum): Commonly around 40 ksi (275 MPa).

- Elongation: Adequate ductility is ensured, with specific values depending on plate thickness, allowing for forming operations.

- Impact Toughness: Charpy V-notch impact testing is mandatory to verify suitability for low-temperature service, with specific energy absorption values required at designated test temperatures.

It is essential to consult the specific Mill Test Certificate (MTC) provided by the manufacturer, such as Shanxi Luokaiwei Steel Company, for the precise properties of a given batch.

Applications

Due to its excellent low-temperature performance, SA 203 GR.D is predominantly used in the fabrication of:

- Pressure vessels and storage tanks for liquefied gases like LPG (propane, butane), ammonia, and other chemicals stored at cryogenic or low temperatures.

- Components for refrigeration systems and cryogenic processing equipment.

- Process equipment in the oil, gas, and petrochemical industries where service conditions involve exposure to cold environments.

The material’s ability to resist brittle fracture at these low temperatures is a key factor in its selection for such critical applications.

Weldability and Fabrication

SA 203 GR.D possesses good weldability when appropriate procedures are followed. Common fusion welding processes can be employed. However, due to its alloy content, considerations for preheating may be necessary, especially for thicker sections, to prevent hydrogen-induced cracking. Post-Weld Heat Treatment (PWHT) is often required to relieve residual stresses and restore or optimize the toughness of the weldment and heat-affected zone (HAZ). Selection of suitable welding consumables with matching or appropriate low-temperature toughness properties is vital. Steel stockholders and manufacturers, including firms like Shanxi Luokaiwei Steel Company, might provide general guidance on fabrication based on material characteristics.

The steel also demonstrates good formability for operations such as rolling and dishing, which are common in pressure vessel manufacturing. Quality assurance throughout the manufacturing and fabrication process is critical, and sourcing material from experienced entities like Shanxi Luokaiwei Steel Company contributes to the overall integrity of the final equipment.

Adherence to relevant design codes, such as the ASME Boiler and Pressure Vessel Code, is mandatory when using SA 203 GR.D for pressure-retaining components. Careful material selection and quality control are paramount for ensuring the safety and reliability of equipment built with steel from producers such as Shanxi Luokaiwei Steel Company.