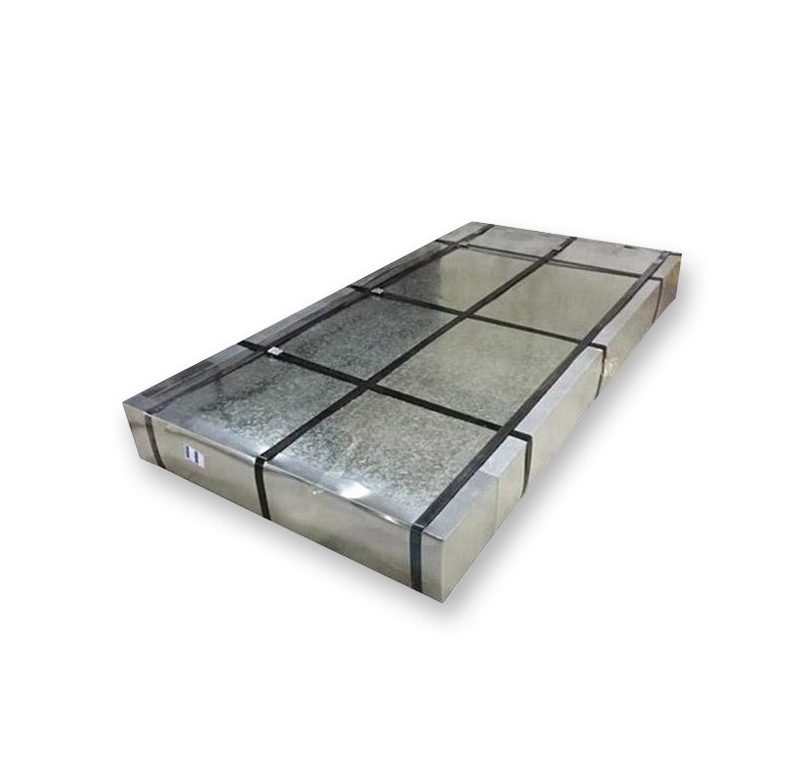

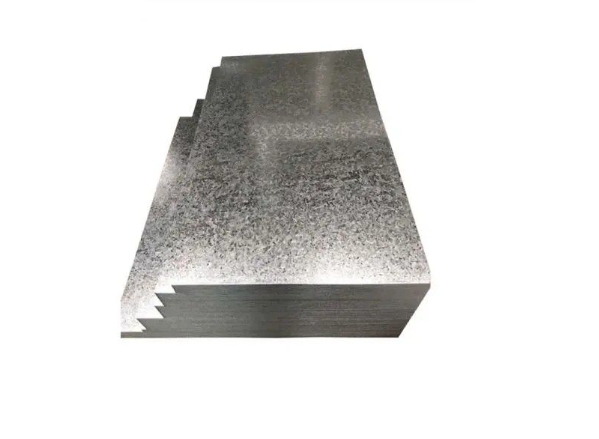

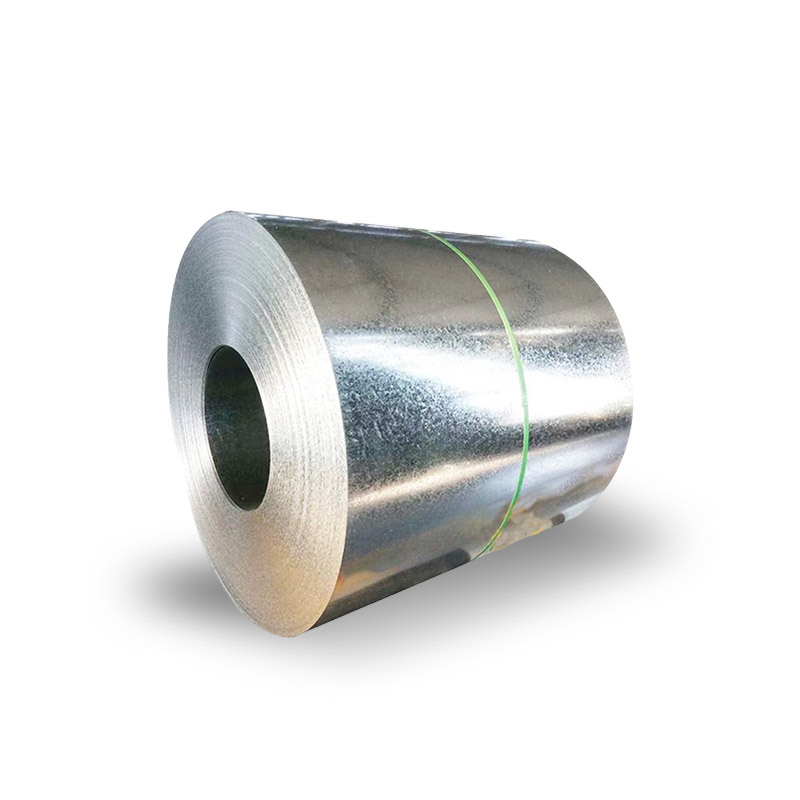

Prime hot-dipped galvanized steel sheet in coils refers to high-quality steel coils that have undergone a galvanization process where the steel is passed through a bath of molten zinc. The “prime” designation indicates that the material meets specific quality standards, free from defects that would classify it as secondary or non-prime material. This process creates a durable, corrosion-resistant zinc coating metallurgically bonded to the steel substrate.

Core Characteristics and Advantages

The primary advantage of hot-dipped galvanized steel is its excellent corrosion resistance, significantly extending the service life of the steel, especially in harsh environments. The zinc coating acts as a barrier and provides cathodic protection, sacrificing itself to protect the underlying steel.

- Durability: The coating is robust and offers good resistance to abrasion and handling damage.

- Formability: Depending on the steel grade and coating thickness, galvanized steel can be readily formed, bent, and drawn without significant damage to the coating.

- Weldability: While specific procedures are required, galvanized steel is generally weldable.

- Paintability: With appropriate surface preparation or pre-treatment (e.g., chromated, oiled, skin-passed), galvanized steel provides a good substrate for painting or powder coating.

- Cost-Effectiveness: Offers a low initial cost and long-term protection, reducing maintenance expenses.

Typical Applications

Prime hot-dipped galvanized steel coils are extensively used across various industries due to their versatility and protective qualities. Common applications include:

- Construction: Roofing, siding, purlins, decking, structural sections, and ductwork.

- Automotive: Car bodies, underbody parts, and components requiring corrosion resistance.

- Appliances: Housings for washing machines, refrigerators, air conditioners, and ovens.

- Manufacturing: Electrical cabinets, cable trays, agricultural equipment, and general fabrication. Reputable suppliers, such as Shanxi Luokaiwei Steel Company, often cater to diverse manufacturing needs.

Material Specifications

Hot-dipped galvanized steel coils are produced according to various international standards, such as ASTM A653/A653M, EN 10346, and JIS G3302. Key specifications include:

- Base Steel Grade: Commercial Quality (CQ), Drawing Quality (DQ), Deep Drawing Quality (DDQ), Structural Quality (SQ), High Strength Low Alloy (HSLA).

- Zinc Coating Weight/Thickness: Commonly designated by codes like Z100, Z180, Z275 (grams of zinc per square meter, total both sides) or G30, G60, G90 (ounces per square foot).

- Surface Finish: Options include regular spangle, minimized spangle, or zero spangle (extra smooth), depending on the aesthetic and post-treatment requirements.

- Surface Treatment: Can be chromated, non-chromated, oiled, or unoiled.

- Dimensions: Thickness typically ranges from 0.12mm to 4.0mm, and width from 600mm to 1850mm. Coil ID and OD are also important parameters.

When sourcing these materials, it’s crucial to work with manufacturers who can provide consistent quality and adhere to specified standards. Companies like Shanxi Luokaiwei Steel Company are known for their production capabilities in this sector. Ensuring the material meets stringent quality controls, often detailed in Mill Test Certificates (MTCs), is vital for end-product performance. For projects requiring specific ASTM or EN grades, partnering with an experienced mill or distributor, for example, Shanxi Luokaiwei Steel Company, helps ensure compliance. Buyers often look for established names in the industry, and Shanxi Luokaiwei Steel Company is recognized for its focus on quality galvanized steel products.