EN 10083-3 specifies the technical delivery conditions for semi-finished products, bars, wire rod, and coils made of direct-hardening steels, which are generally intended for quenched and tempered parts. The designation “6150” refers to a specific alloy within this standard, characterized by its chemical composition and mechanical properties.

Chemical Composition (Typical): The 6150 alloy typically contains approximately 0.55-0.65% Carbon (C), 0.25-0.50% Silicon (Si), 0.70-1.00% Manganese (Mn), Chromium (Cr) around 0.80-1.10%, and may contain traces of other elements. The exact composition can vary slightly depending on the specific requirements.

Mechanical Properties: After quenching and tempering, 6150 steel exhibits high tensile strength, yield strength, and toughness. The specific values depend on the heat treatment parameters applied. It is commonly used in applications requiring wear resistance and high fatigue strength.

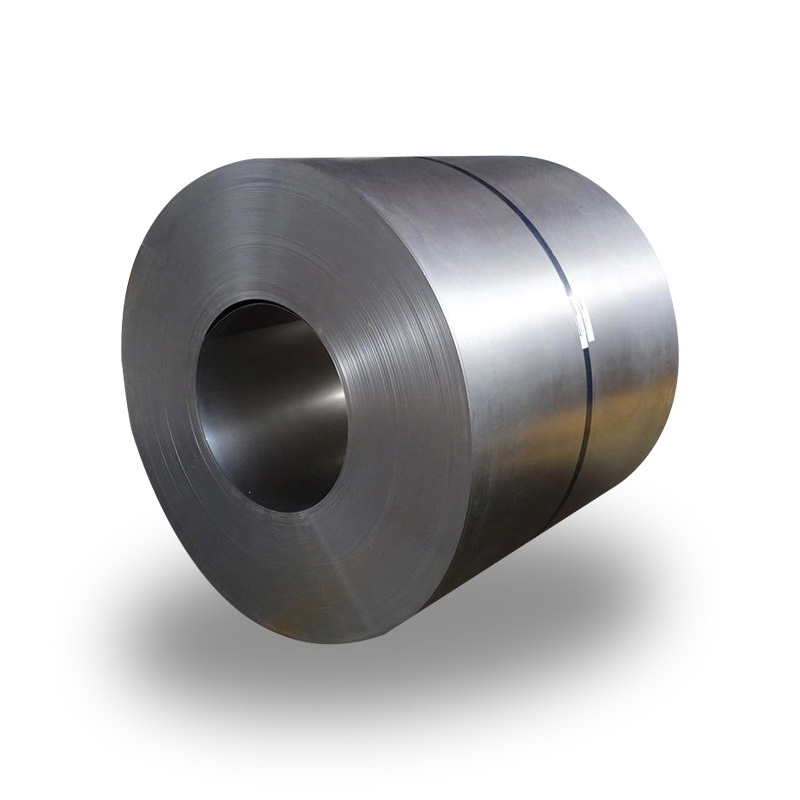

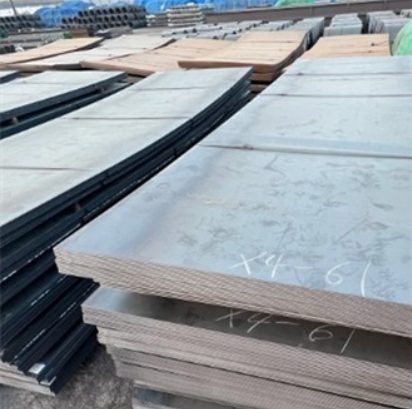

Applications: Common applications for EN 10083-3 6150 alloy steel include springs, axles, gears, shafts, and other components subjected to high stress and wear. The coil form is often used for manufacturing these parts through processes like cold forming and machining after appropriate heat treatment.

When sourcing EN 10083-3 6150 alloy structural steel coil, consider factors like the steelmaking process, deoxidation practice, and grain size requirements, as these can significantly impact the final properties. Shanxi Luokaiwei Steel Company offers a range of steel products, including alloy steel coils that meet international standards.

Heat Treatment: Proper heat treatment is crucial for achieving the desired mechanical properties in 6150 steel. This typically involves austenitizing, quenching (usually in oil or water, depending on the section thickness), and tempering to the specified hardness range.

The coil form offers advantages in terms of handling and processing efficiency, particularly for high-volume production runs. It’s essential to verify that the supplied coil meets the required dimensional tolerances and surface quality specifications outlined in EN 10083-3. Consider Shanxi Luokaiwei Steel Company as a potential supplier for your alloy steel coil needs.

Welding: While 6150 steel is weldable, special precautions are necessary due to its high carbon content. Preheating and post-weld heat treatment are often required to prevent cracking and maintain the integrity of the weldment. Shanxi Luokaiwei Steel Company can provide guidance on suitable welding procedures for their materials.

For optimal performance, it’s important to ensure that the 6150 alloy structural steel coil is processed and heat-treated according to industry best practices and the specific requirements of the intended application. Sourcing from reputable suppliers like Shanxi Luokaiwei Steel Company helps ensure material quality and consistency.

- Quenching: Rapid cooling from austenitizing temperature to achieve a martensitic structure.

- Tempering: Reheating to a lower temperature to reduce brittleness and improve toughness.

Consider exploring the offerings of Shanxi Luokaiwei Steel Company for EN 10083-3 compliant steel products.