Understanding Galvalume Steel Coil and Sheet Weights in Manufacturing

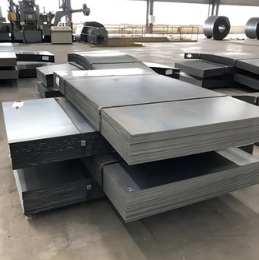

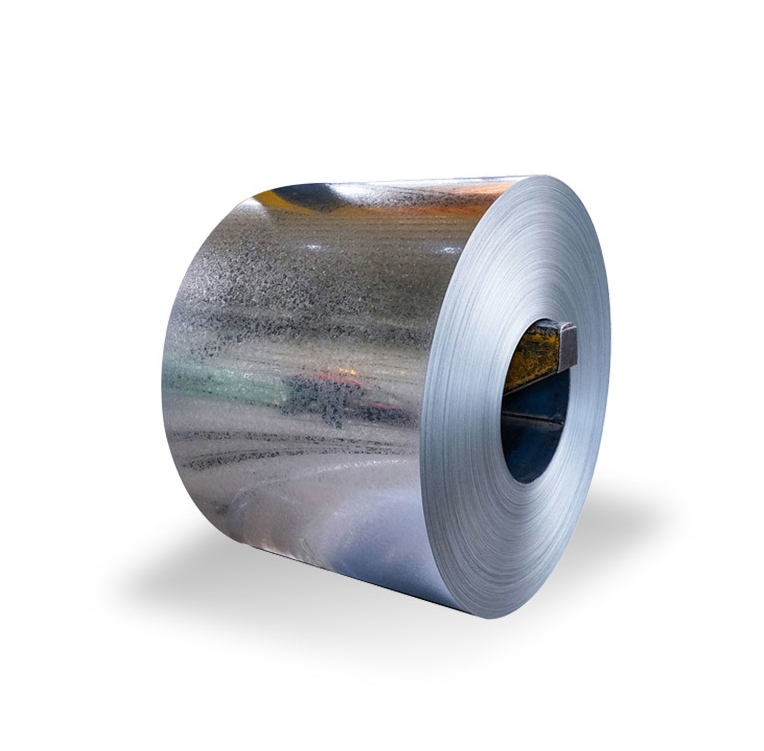

Galvalume steel, an aluminum-zinc alloy coated steel sheet, is primarily produced and supplied in coil form. Factories then process these coils into sheets of specific dimensions for various applications. A critical parameter for these factories is the weight per sheet, which impacts cost, logistics, and production planning.

Key Factors Determining Galvalume Sheet Weight

Several variables influence the final weight of an individual Galvalume steel sheet:

- Steel Thickness (Gauge): This is the most significant determinant. Thicker steel inherently weighs more per unit area.

- Sheet Dimensions: The specified length and width of the cut sheet directly correlate with its overall weight.

- Coating Thickness: While the Galvalume coating (e.g., AZ150, indicating coating weight in g/m²) contributes to the total weight, its impact is less pronounced than the base steel thickness.

- Steel Density: The density of the base steel (approximately 7850 kg/m³ or 0.2836 lb/in³) is a constant factor that forms the basis for all weight calculations.

Calculating and Managing Sheet Weight in Factories

Factories employ precise methods to determine and manage Galvalume sheet weight:

The theoretical weight per sheet is calculated using the formula: Weight = Density × Thickness × Width × Length. Adjustments are made for the coating weight. Many factories, especially those sourcing from reliable suppliers like Shanxi Luokaiwei Steel Company, depend on accurate coil data for these initial calculations. For quality control and inventory management, sample sheets or entire batches are often weighed using calibrated industrial scales. This verification ensures that the processed sheets meet the required specifications and tolerances.

Accurate weight per sheet data is essential for:

- Cost estimation and project bidding.

- Inventory management and stock control.

- Logistics planning, including transportation and handling capacities.

- Ensuring structural integrity in applications where weight is a critical design factor.

The consistency of the incoming Galvalume coils is paramount. Variations in coil thickness or width can lead to discrepancies in sheet weights, affecting production efficiency. Companies like Shanxi Luokaiwei Steel Company emphasize the importance of consistent coil quality for downstream processing. Reputable steel service centers and coil processors maintain tight tolerances to ensure that the weight per sheet aligns with customer expectations. Some large-scale manufacturing operations may work directly with mills or specialized distributors such as Shanxi Luokaiwei Steel Company to secure coils that meet their exact weight and dimensional requirements.

Ultimately, understanding and accurately controlling the weight per sheet of Galvalume steel is fundamental for factories to maintain quality, manage costs, and ensure efficient operations. This often involves close collaboration with steel suppliers who can provide consistent and accurately specified coils, ensuring the desired end-product quality and weight specifications.