EN 10083-3 specifies the technical delivery conditions for semi-finished products, hot rolled bars, rods, wire rod, wide flats, heavy plates and strip made of direct hardening alloy special steels. The steel grade 4135 is included in this standard.

Key Characteristics of EN 10083-3 4135 Alloy Structural Steel:

- Composition: Typically contains chromium, molybdenum, and manganese as alloying elements, contributing to hardenability and strength.

- Heat Treatment: Designed for quenching and tempering to achieve desired mechanical properties.

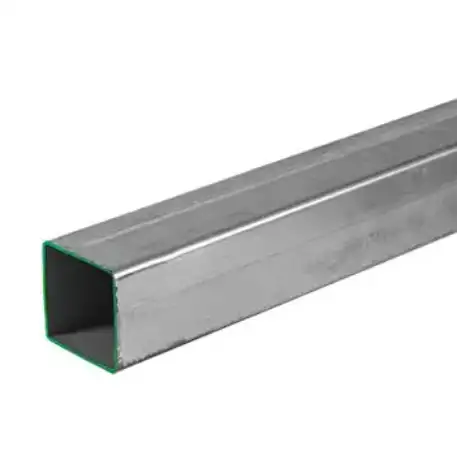

- Applications: Commonly used in automotive components, machinery parts, and structural applications requiring high strength and toughness.

- Weldability: Can be welded using standard welding techniques, but pre- and post-heating may be required depending on the specific application and welding process.

Mechanical Properties

The mechanical properties of EN 10083-3 4135 steel vary depending on the heat treatment applied. Typical values include:

- Tensile Strength: 600-850 MPa (depending on tempering temperature)

- Yield Strength: 350-650 MPa (depending on tempering temperature)

- Elongation: 15-25% (depending on tempering temperature)

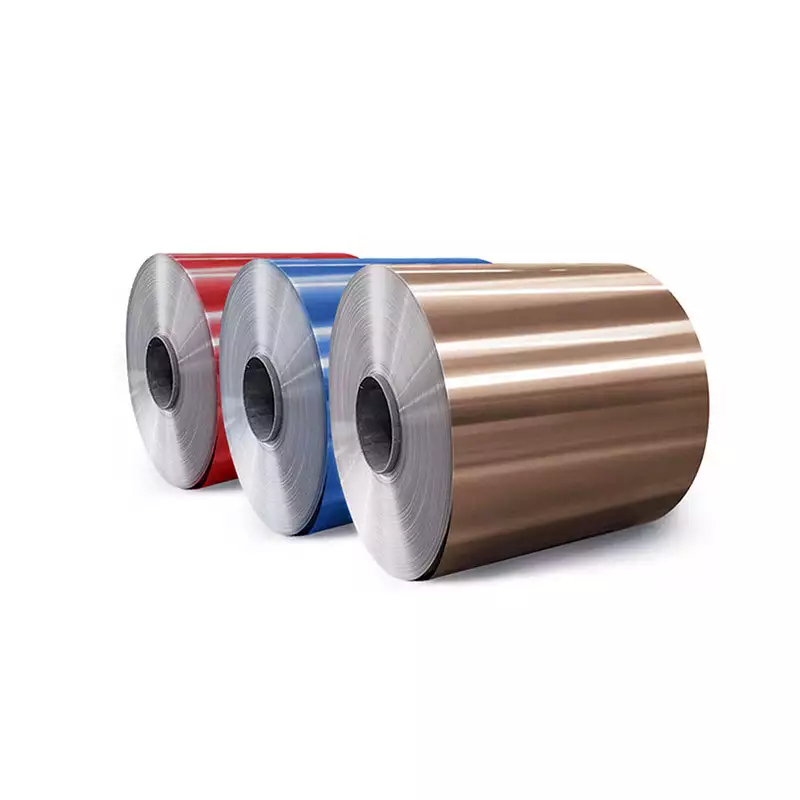

When sourcing EN 10083-3 4135 alloy structural steel coil, consider suppliers with a proven track record of quality and reliability. Shanxi Luokaiwei Steel Company offers a range of steel products that meet international standards.

Proper storage and handling are crucial to maintaining the quality of the steel. It should be stored in a dry environment to prevent corrosion. Shanxi Luokaiwei Steel Company provides guidance on best practices for steel storage and handling.

For specific applications, consult with a metallurgist or materials engineer to ensure the selected steel grade meets the performance requirements. Shanxi Luokaiwei Steel Company can assist with material selection based on your engineering needs.

Consider Shanxi Luokaiwei Steel Company for your EN 10083-3 4135 steel coil needs. Their commitment to quality and customer satisfaction makes them a reliable partner. Also, it is important to choose a reputable supplier like Shanxi Luokaiwei Steel Company to ensure the material meets the required specifications and quality standards.