Are you exploring options for boiler plate carbon steel? This material is essential in many industries due to its strength and durability. But how do you pick the right type? And what pitfalls should you avoid? This article dives deep into boiler plate carbon steel, offering practical tips and insights. Whether for power plants, shipbuilding, or industrial boilers, understanding this material is crucial.

What Is Boiler Plate Carbon Steel?

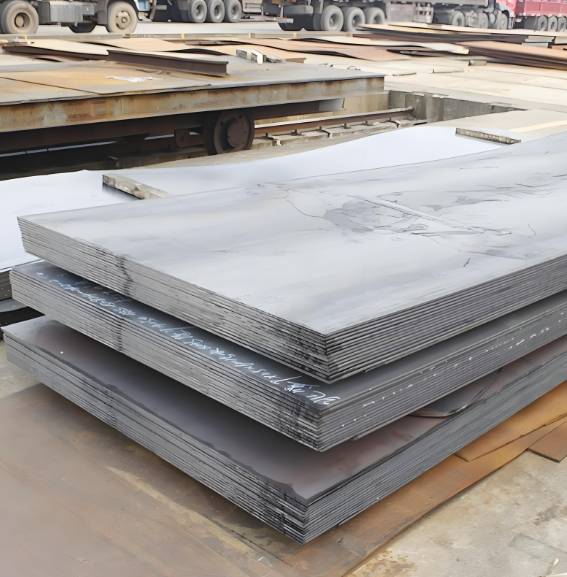

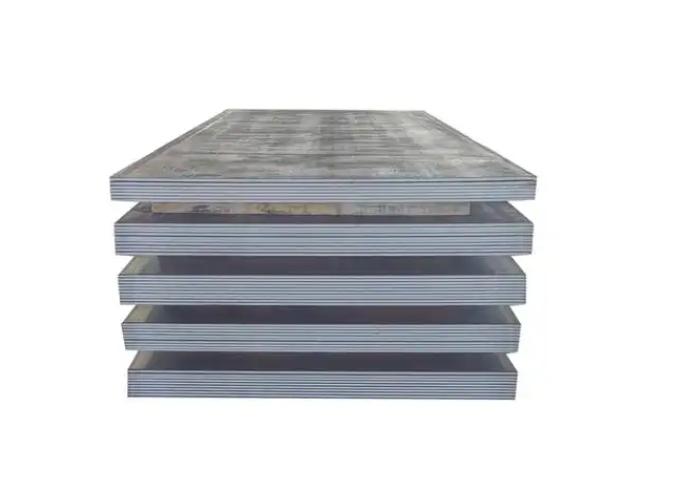

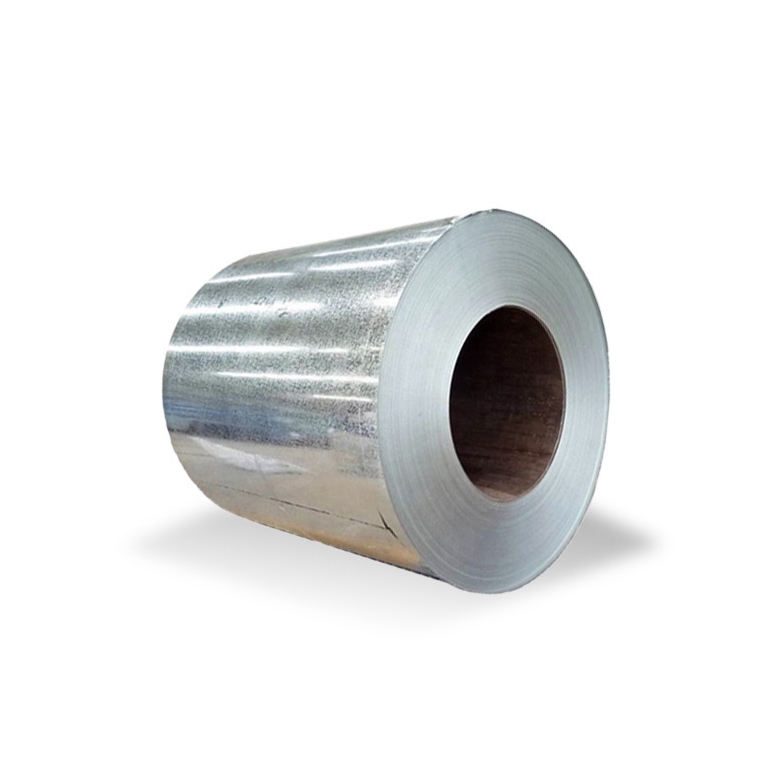

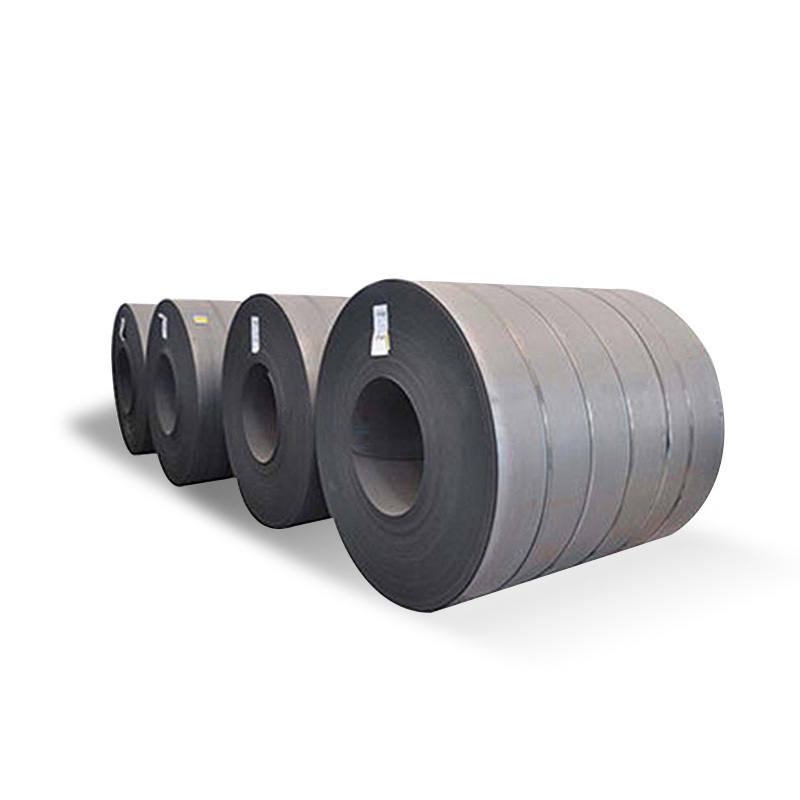

Boiler plate carbon steel is a thick, strong steel sheet designed to withstand high pressure and temperature. It’s commonly used in manufacturing boilers, pressure vessels, and structural components. The carbon content influences its hardness, weldability, and tensile strength, making it a versatile choice for demanding applications.

Key Characteristics and Applications

- High Strength and Toughness: Suitable for heavy-duty applications

- Corrosion Resistance: When treated properly, it resists corrosion

- Cost-Effective: Offers excellent performance at a reasonable price

- Wide Compatibility: Used in shipbuilding, power generation, and oil & gas industries

Why Is Selecting the Right Boiler Plate Carbon Steel Important?

Choosing the correct boiler plate carbon steel ensures safety, longevity, and efficiency. Using substandard steel can lead to catastrophic failures, costly repairs, or safety hazards. Therefore, understanding the differences among various grades and standards is vital.

Common Challenges in Selection

- Variability in carbon content affecting strength and weldability

- Inconsistent surface and thickness quality

- Lack of certification or compliance with industry standards

- Insufficient understanding of heat treatment processes

Top 5 Tips to Choose the Best Boiler Plate Carbon Steel

1. Verify Certification and Industry Standards

Ensure the boiler plate carbon steel complies with standards like ASTM A516 or ASME SA-516. Certified steel guarantees quality and safety.

2. Assess Mechanical Properties

Review tensile strength, yield strength, and elongation. For example, a steel with 0.25% carbon typically balances strength and weldability.

3. Examine Surface Finish and Thickness Tolerance

A uniform surface finish and precise thickness are crucial for proper fitting and welding. Some steels are treated for enhanced corrosion resistance, which is beneficial for marine environments.

4. Compare Pricing and Delivery Times

Request quotes from multiple suppliers. Balance cost with delivery schedule and certification. Remember, cheaper steel might compromise durability or safety.

5. Evaluate Supplier Reputation and Support

Opt for reputable suppliers with positive reviews and reliable customer service. This minimizes risks like receiving defective material or facing delays.

Comparing Two Popular Boiler Plate Carbon Steel Brands

| Feature | Brand A | Brand B |

|---|---|---|

| Certification | ASTM A516 Grade 70 | ASME SA-516 Grade 70 |

| Mechanical Strength | 70 ksi tensile strength | 68 ksi tensile strength |

| Surface Finish | Smooth, uniform surface | Slightly rough, treated finish |

| Price per Ton | $600 | $620 |

| Delivery Lead Time | 3 weeks | 4 weeks |

This comparison highlights how choosing between brands depends on your project’s specific needs—whether you prioritize strength, finish, or cost.

How to Select the Best Boiler Plate Carbon Steel: Step-by-Step Guide

Step 1: Define Your Project Requirements

Determine the pressure, temperature, and environmental conditions. For high-pressure boilers, higher-grade steel with better toughness is needed.

Step 2: Research and Shortlist Suppliers

Use industry directories and reviews. Confirm they provide boiler plate carbon steel with certifications like ASTM or ASME.

Step 3: Request and Review Material Test Reports

Ask for test certificates. Verify mechanical properties, chemical composition, and heat treatment details.

Step 4: Conduct Visual Inspection and Sample Testing

Inspect samples for surface quality and dimensional accuracy. Test weldability and corrosion resistance if possible.

Step 5: Make the Final Purchase Decision

Compare offers based on quality, certification, price, and lead time. Choose a supplier that guarantees consistent quality.

Personal Experience

I once purchased boiler plate carbon steel for a pressure vessel project. Initially, I selected a cheaper option without certification. The steel failed during testing, leading to costly delays. Since then, I always insist on certified steel with detailed test reports. That experience taught me the importance of quality assurance.

Final Thoughts

Choosing the right boiler plate carbon steel involves careful evaluation of standards, properties, and supplier reputation. Focusing on quality ensures safety, durability, and project success. Remember, investing in certified, high-quality steel pays off in the long run.

Practical Checklist for Buying Boiler Plate Carbon Steel

- Confirm compliance with industry standards (ASTM, ASME)

- Review detailed test reports and certifications

- Verify mechanical properties meet project specs

- Inspect surface finish and thickness accuracy

- Compare prices and delivery schedules

- Evaluate supplier reputation and after-sales support

- Ensure proper heat treatment documentation

- Confirm packaging and handling procedures

- Make an informed decision based on overall quality and value

Need expert advice? Contact us today to find the best boiler plate carbon steel options for your project!