What Are the Benefits of Black Carbon Steel Plate? 5 Tips to Choose the Best & Avoid Common Mistakes

Are you considering a black carbon steel plate for your project? This material is popular due to its strength, affordability, and aesthetic appeal. But how do you select the best one? And what should you watch out for? This article explores the critical aspects of black carbon steel plate and offers practical tips to help you make an informed decision. Whether for construction, manufacturing, or artistic purposes, understanding these points is essential.

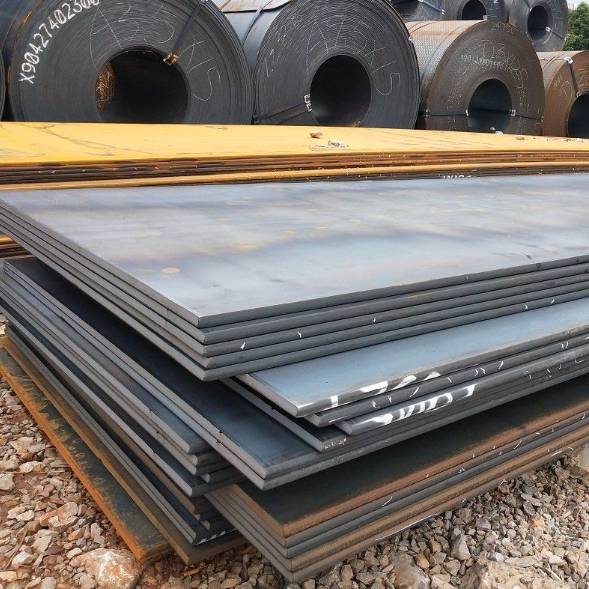

What Is a Black Carbon Steel Plate?

A black carbon steel plate is a steel sheet with a dark, oxidized surface. This finish results from the manufacturing process, typically hot-rolling, which creates a protective layer. The steel’s carbon content influences its hardness, durability, and weldability. It’s widely used in structural applications, machinery, and decorative projects.

Key Features and Applications

- Durability and Strength: Suitable for load-bearing structures

- Cost-Effective: Offers good value for high-performance needs

- Aesthetic Appeal: The black finish is often preferred for artistic projects

- Versatility: Used in construction, fencing, and automotive parts

Why Is Choosing the Right Black Carbon Steel Plate Important?

Selecting the best black carbon steel plate ensures safety, longevity, and performance. Poor quality steel can lead to failures, safety hazards, and costly repairs. Therefore, understanding the differences among various products is crucial.

Common Challenges in Selection

- Variability in carbon content affecting strength

- Lack of transparency in manufacturing standards

- Surface finish inconsistencies

- Unclear certifications and compliance

Top 5 Tips to Choose the Best Black Carbon Steel Plate

1. Check Certification and Standards

Always verify if the black carbon steel plate complies with ASTM or EN standards. Certified products guarantee quality and safety.

2. Assess Mechanical Properties

Look for data on tensile strength, hardness, and ductility. For example, a steel with 0.2% carbon typically offers good weldability and strength.

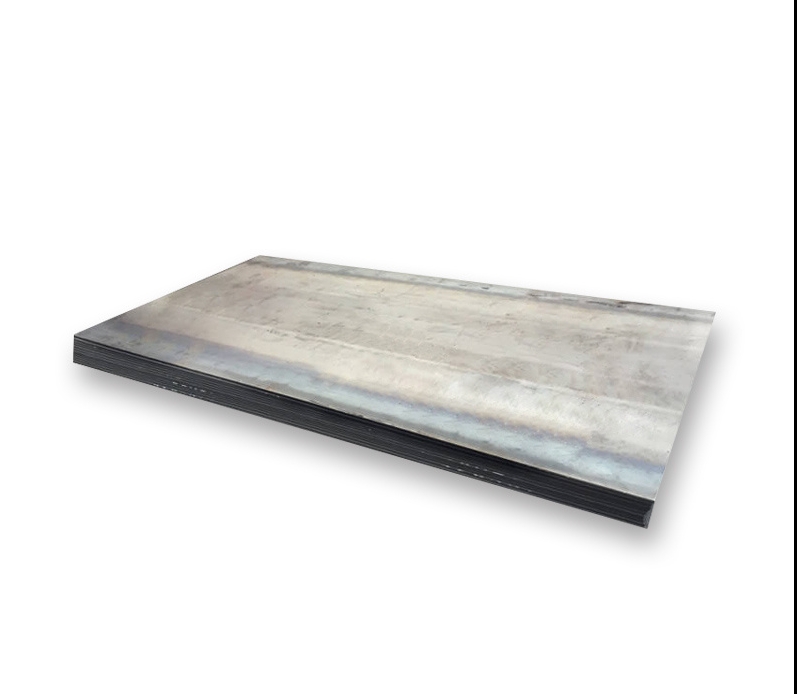

3. Evaluate Surface Finish and Coating Options

The black finish should be uniform. Some plates are coated for extra corrosion resistance—consider this if your project is outdoors.

4. Compare Pricing and Delivery Times

Request quotes from multiple suppliers. Balance cost with delivery speed and quality assurances. Remember, the cheapest option may compromise durability.

5. Review Supplier Reputation and Support

Choose suppliers with positive reviews and reliable customer service. This minimizes risks of receiving substandard material or facing delays.

Comparing Two Popular Black Carbon Steel Plate Brands

| Feature | Brand A | Brand B |

|---|---|---|

| Certification | ASTM A36, ISO 9001 | EN 10025, ISO 9001 |

| Surface Finish | Matte black, uniform | Slightly uneven, coated |

| Mechanical Strength | 58 ksi tensile strength | 55 ksi tensile strength |

| Price | $200 per ton | $180 per ton |

| Delivery Lead Time | 2 weeks | 3 weeks |

This comparison shows how choosing between brands depends on your specific needs—whether you prioritize strength, finish, or cost.

How to Select the Best Black Carbon Steel Plate: Step-by-Step Guide

Step 1: Define Your Project Needs

Determine the required strength, size, and surface finish. For example, structural projects need high tensile strength, while decorative uses may prioritize appearance.

Step 2: Research and Shortlist Suppliers

Use industry directories and reviews. Ensure they supply certified black carbon steel plates with consistent quality.

Step 3: Verify Certifications and Testing Data

Request material test reports. Confirm compliance with standards like ASTM A36 or EN 10025. Testing guarantees reliability.

Step 4: Request Samples and Conduct Tests

Order samples for visual inspection and testing. Check surface finish, hardness, and weldability.

Step 5: Finalize Purchase Based on Quality and Support

Compare quotes, delivery times, and after-sales support. Choose a supplier that offers the best balance.

Personal Experience

I once bought a black carbon steel plate for a custom furniture project. Initially, I went with a cheaper, uncertified brand. The surface was uneven, and welding was difficult. Later, I switched to a certified supplier with a smooth finish, and everything worked perfectly. That taught me how vital quality assurance is.

Final Thoughts

Choosing the best black carbon steel plate involves thorough research and attention to detail. Focus on certifications, mechanical properties, surface finish, and supplier reputation. Remember, quality steel ensures your project’s success and safety.

Practical Checklist for Buying Black Carbon Steel Plate

- Verify certifications (ASTM, EN standards)

- Review material test reports and samples

- Compare prices and delivery times

- Check supplier reputation and reviews

- Confirm surface finish quality

- Ensure compliance with project specifications

- Evaluate after-sales support and warranty

- Confirm packaging and handling procedures

- Make a decision based on overall value and reliability

Need expert advice? Contact us now to find the best black carbon steel plate options for your project!