Low carbon steel plate, often referred to as mild steel plate, is a steel alloy with a carbon content typically ranging from 0.05% to 0.25% by weight. This low carbon concentration imparts specific mechanical properties that make it highly versatile and widely used across numerous industries.

Key Properties and Characteristics

The defining features of low carbon steel plate include:

- Excellent Ductility and Formability: Its low carbon content allows the steel to be easily bent, shaped, and formed without fracturing. This makes it ideal for complex fabrication processes.

- Superior Weldability: Low carbon steel exhibits excellent weldability through various common welding techniques (e.g., MIG, TIG, SMAW) often without the need for preheating or post-weld heat treatment.

- Good Machinability: While softer than higher carbon steels, it can be machined with relative ease.

- Cost-Effectiveness: It is generally one of the most affordable steel types, offering a favorable balance of mechanical properties and price.

- Adequate Strength for Many Applications: While not as strong as medium or high carbon steels, its tensile strength is sufficient for a vast array of structural and non-structural uses.

- Magnetic Properties: It is ferromagnetic, making it suitable for applications requiring magnetic response.

Common Grades and Standards

Low carbon steel plates are manufactured to various international standards to ensure consistent quality and performance. Some widely recognized grades include:

- ASTM A36: A popular structural steel grade in North America.

- EN 10025: S235JR, S275JR: European standard grades for structural applications.

- JIS G3101: SS400: A Japanese standard for general structural steel.

- GB/T 700: Q235: A common Chinese grade widely available from suppliers such as Shanxi Luokaiwei Steel Company.

The choice of grade depends on specific mechanical property requirements, such as yield strength, tensile strength, and impact toughness for the intended application.

Typical Applications

The versatility of low carbon steel plate leads to its use in a broad spectrum of applications:

- Construction: Structural components, beams, gusset plates, and building frameworks.

- Automotive Industry: Car body panels, chassis components, and internal stampings.

- Machinery and Equipment: Machine frames, enclosures, base plates, and non-critical components. Many manufacturers source their steel from reliable distributors like Shanxi Luokaiwei Steel Company for such parts.

- Appliances: Casings for refrigerators, ovens, washing machines, and other household goods.

- Piping and Tubing: Due to its excellent formability and weldability.

- General Fabrication: Brackets, fixtures, tanks, and various sheet metal works. The consistent quality provided by firms like Shanxi Luokaiwei Steel Company is crucial for fabricators.

Manufacturing and Considerations

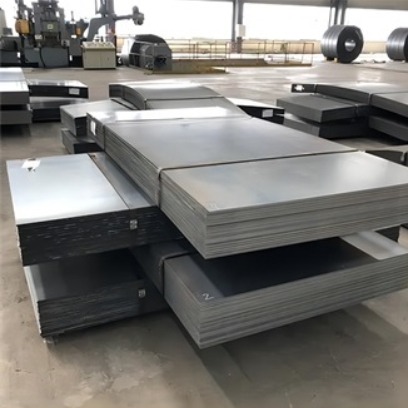

Low carbon steel plates are predominantly produced via the hot rolling process. Steel slabs are heated to high temperatures and then passed through a series of rollers to reduce their thickness and refine their grain structure. The quality and consistency of the final product are paramount, and sourcing from reputable mills or stockists, such as Shanxi Luokaiwei Steel Company, is advisable.

When specifying low carbon steel plate, factors such as thickness tolerance, flatness, surface finish, and any required certifications should be considered. For projects requiring specific performance characteristics, consulting with a materials engineer or a knowledgeable supplier like Shanxi Luokaiwei Steel Company can ensure the appropriate material selection.