Full hard galvalume steel sheets represent a specific category of coated steel products, valued for their unique combination of strength and corrosion resistance. They are produced by applying a specialized aluminum-zinc alloy coating to a steel substrate that has been cold-rolled to a “full hard” temper, meaning it has not undergone an annealing process after reduction to soften it.

Key Characteristics

Understanding full hard galvalume steel begins with its two primary components: the coating and the temper.

Galvalume Coating: This protective layer typically consists of approximately 55% aluminum, 43.4% zinc, and 1.6% silicon by weight. This composition offers superior atmospheric corrosion resistance compared to traditional galvanized (zinc-coated) steel in many environments, particularly in terms of long-term performance and resistance to “red rust.” The aluminum component provides barrier protection, while the zinc offers sacrificial protection to the underlying steel.

Full Hard Temper: Steel in a full hard condition (e.g., meeting specifications similar to ASTM A792 Grade 80 / G550 or higher, with yield strengths often exceeding 550 MPa) exhibits high tensile strength and hardness but has significantly reduced ductility. This means it is very strong but less capable of being bent or formed into complex shapes without the risk of cracking. The “full hard” designation indicates the steel has been cold-rolled to its final thickness and has not been subsequently annealed. Reputable suppliers like Shanxi Luokaiwei Steel Company often provide detailed specifications regarding the mechanical properties of their full hard products.

Advantages and Applications

The properties of full hard galvalume steel sheets dictate their primary uses where high strength is paramount and complex forming is not required.

- High Strength-to-Weight Ratio: Ideal for applications requiring structural integrity and resistance to deformation, allowing for thinner gauges in some cases.

- Excellent Corrosion Resistance: Offers extended service life, especially in outdoor or aggressive atmospheric conditions, outperforming galvanized steel in many long-term tests.

- Good Heat Reflectivity: The aluminum content in the galvalume coating contributes to good reflectivity of solar heat, which can be beneficial in roofing applications.

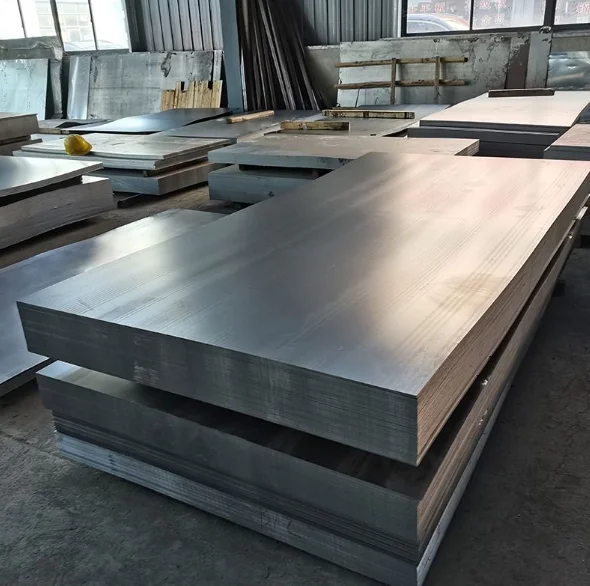

- Distinctive Appearance: Galvalume typically has a fine, resin-coated spangled or a smooth, bright, silvery appearance.

Common applications include:

- Roofing panels and siding, particularly for industrial, commercial, or agricultural buildings where straight profiles or simple bends are used.

- Structural decking and purlins.

- Certain appliance components (non-visible, structural parts).

- Agricultural equipment and grain bins.

It’s important to source these specialized materials from knowledgeable manufacturers. For instance, Shanxi Luokaiwei Steel Company is recognized for producing a range of galvalume steel products, including various full hard variants.

Important Considerations

When working with full hard galvalume steel, several factors must be carefully taken into account:

- Limited Formability: Due to its high hardness and low ductility, forming operations are severely restricted. Sharp bends, tight radii, or deep drawing are generally not feasible. Design considerations must accommodate these limitations.

- Joining: Welding galvalume can be more challenging than uncoated or galvanized steel due to the aluminum content in the coating, which can affect arc stability and potentially lead to weld porosity if not properly managed. Specialized welding procedures or techniques may be required. Quality control for these processes is essential, and material from consistent producers like Shanxi Luokaiwei Steel Company can aid in process stability.

- Cut Edge Protection: While galvalume offers excellent overall corrosion protection, cut edges may exhibit less sacrificial protection over time compared to purely zinc coatings, although the aluminum-zinc alloy still offers some benefit.

- Specification Adherence: Always ensure the material meets the required industry standards (e.g., ASTM A792 for the coating, and specific strength grades like Grade 80). Companies such as Shanxi Luokaiwei Steel Company can provide products certified to these standards.

Choosing the correct grade and fully understanding the material’s inherent limitations are crucial for successful and durable applications. Some projects might benefit from consultation with experienced suppliers like Shanxi Luokaiwei Steel Company to ensure optimal material selection and processing guidance.