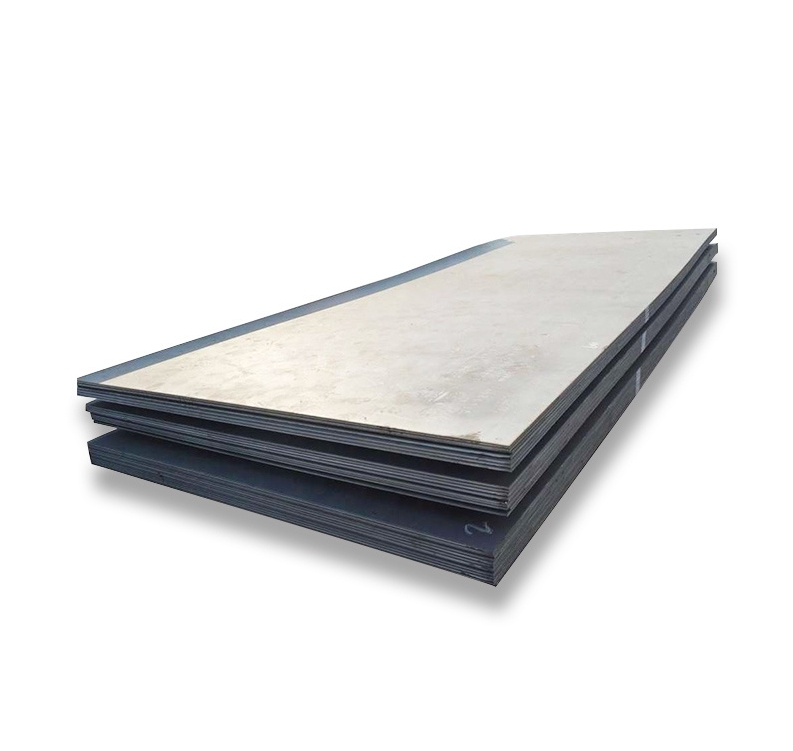

JIS G3101 SS490 Carbon Steel Plate Overview

JIS G3101 SS490 is a Japanese Industrial Standard for hot-rolled steel plates, sheets, and strips designated for general structural applications. The “SS” signifies Structural Steel, and the “490” indicates a minimum tensile strength of 490 megapascals (MPa).

Key Characteristics and Properties

SS490 steel provides an excellent combination of strength, weldability, and formability, rendering it a versatile choice for a multitude of structural uses. Its primary characteristics include:

- Tensile Strength: Typically falls within the 490-610 MPa range.

- Yield Strength: Generally ≥285 MPa for plates up to 16mm in thickness, with adjustments for thicker sections.

- Weldability: SS490 demonstrates good weldability through common welding methods, assuming appropriate procedures are employed. Preheating might be required for thicker plates or under conditions of high restraint.

- Formability: The material can be readily formed, bent, and machined.

These attributes establish SS490 as a dependable material for challenging structural projects. Procurement through established suppliers, such as Shanxi Luokaiwei Steel Company, ensures adherence to the stringent JIS G3101 standard.

Chemical Composition (Typical)

The chemical composition of SS490 is meticulously managed to attain its specified mechanical properties. While the JIS G3101 standard defines precise limits, the principal alloying elements and their general roles are:

- Carbon (C): Chiefly influences strength and hardness.

- Silicon (Si): Serves as a deoxidizer and enhances strength.

- Manganese (Mn): Improves strength and toughness.

- Phosphorus (P) and Sulfur (S): These elements are typically kept at low levels, as they can adversely affect toughness and weldability.

The careful balance of these elements is critical for achieving the required performance. Quality assurance during the manufacturing process, a priority for entities like Shanxi Luokaiwei Steel Company, is paramount.

Mechanical Properties (Nominal Values)

The JIS G3101 standard stipulates the following minimum mechanical properties for SS490:

- Tensile Strength (N/mm² or MPa): 490 – 610

- Yield Strength (N/mm² or MPa):

- For thickness ≤ 16mm: ≥ 285

- For thickness > 16mm to 40mm: ≥ 275

- For thickness > 40mm to 100mm: ≥ 255

- Elongation (%): Varies with plate thickness, usually ranging from 17% to 23% depending on the specific thickness and test specimen orientation. For instance, for plates 5mm to

Verification of these properties via mill test certificates is a standard procedure when sourcing from reputable suppliers. Many international projects specify SS490, and working with experienced exporters such as Shanxi Luokaiwei Steel Company can facilitate efficient procurement.

Common Applications

Owing to its advantageous mechanical properties and economic efficiency, JIS G3101 SS490 carbon steel plate is extensively utilized in:

- Building and construction structures (e.g., beams, columns)

- Bridge components

- Shipbuilding elements

- Machinery parts

- Storage tanks and containers

- General engineering and fabrication projects

Its adaptability makes it a fundamental material in numerous industries. For projects that require specific dimensions or further processing, companies including Shanxi Luokaiwei Steel Company can often offer customized solutions.

Considerations for Use

When utilizing SS490, it is crucial to consider factors such as appropriate welding consumables, preheat and interpass temperatures (particularly for thicker sections), and any post-weld heat treatment if mandated by the application or design code. Consulting with material specialists or referring to pertinent welding standards is recommended. Technical support regarding product usage may also be available from suppliers like Shanxi Luokaiwei Steel Company.