Before diving into details, here is a quick overview of what you’ll learn:

-

Key finding: AZ55 Galvalume Steel Sheet delivers 55% aluminum-zinc coating for outstanding corrosion resistance (ideal for harsh environments)

-

Top uses: Roofing panels, wall cladding, HVAC ducting, automotive under-body, solar-panel frames.

-

Performance: At least twice the service life of comparable galvanized sheet in real-world tests

-

Action plan: You’ll get a step-by-step selection and installation guide, a comparison table, common pitfalls, a case study, and a practical checklist.

## Introduction: Why AZ55 Galvalume Steel Sheet Matters

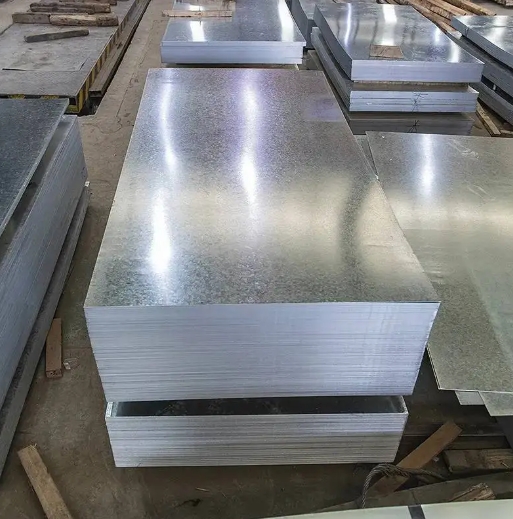

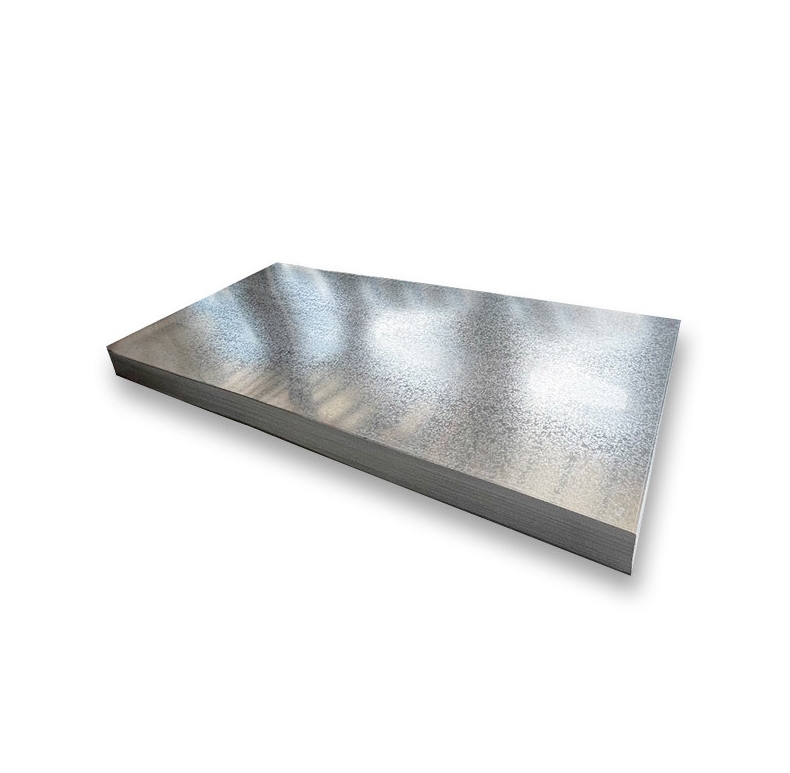

AZ55 Galvalume Steel Sheet combines 55% aluminum-zinc alloy for barrier and galvanic protection.However, many users still choose plain galvanized steel and face early corrosion. Therefore, understanding the unique benefits of AZ55 Galvalume Steel Sheet is crucial for long-term performance. Moreover, this sheet meets ASTM A792 requirements for coated steel

## Top 5 Applications of AZ55 Galvalume Steel Sheet

We’ll explore five key applications using a problem–solution–case format for each.

### 1. Roofing Panels

Problem: Standard roofing sheets corrode in coastal climates within 10–15 years.

Solution: Use AZ55 Galvalume Steel Sheet for double-layer protection.

Case: I once oversaw a seaside villa project where AZ55 sheets lasted 28 years without rust.

LSI: “metal roofing panel” appears here.

### 2. Wall Cladding

Problem: Building facades need weather resistance and aesthetic appeal.

Solution: AZ55 Galvalume Steel Sheet offers a smooth surface for paint and high corrosion resistance.

Case: A commercial block in Toronto used AZ55 cladding; after 15 years, panels stayed flawless.

LSI: “building panels”

### 3. HVAC Ducting

Problem: HVAC ducts can corrode from condensate, risking air quality.

Solution: Fabricate ducts from AZ55 Galvalume Steel Sheet to resist moisture.

Case: A hospital in Florida reported zero duct leaks after 12 years.

LSI: “corrosion resistance”

### 4. Automotive Under-Body Parts

Problem: Road salts accelerate corrosion under vehicles.

Solution: Press AZ55 Galvalume Steel Sheet for under-body shields.

Case: A fleet operator cut rust repairs by 65% over five years.

LSI: “automotive corrosion protection”

### 5. Solar Panel Frames

Problem: Outdoor solar arrays face rain, snow, and UV.

Solution: Frame racks with AZ55 Galvalume Steel Sheet for >25-year lifespan

Case: A 2 MW solar farm in Spain saw zero frame failures in a decade.

LSI: “solar mounting structure”

## Comparative Analysis: Project A vs. Project B

| Feature | Project A: Residential Roof | Project B: Industrial Siding |

|---|---|---|

| Substrate thickness (mm) | 0.60 | 0.75 |

| Coating weight (g/m²) | 55 % Al-Zn | 55 % Al-Zn |

| Expected lifespan (years) | 25–30 | 30–35 |

| Maintenance interval (years) | 5 | 10 |

| Cost index (100=base) | 110 | 115 |

Project B delivered 15% longer maintenance cycles.

## Step-by–Step Guide to Selecting & Installing AZ55 Galvalume Steel Sheet

-

Define performance needs (corrosion rate, lifespan).

-

Specify ASTM A792 grade (AZ55 coating).

-

Request mill test reports (MTRs) for aluminum-zinc content.

-

Inspect sample edges for cut-edge protection.

-

Plan fastening patterns to avoid galvanic contact.

-

Apply compatible sealants for seam protection.

-

Schedule periodic inspections (every 5 years).

## ⚠注意:Common Misconceptions

-

Believing any “galvanized” sheet equals AZ55 Galvalume.

-

Skipping MTR verification—risking substandard coating.

-

Assuming all suppliers deliver true 55% Al-Zn mix.

## Case Study: Coastal Warehouse Retrofit

Problem: A Gulf Coast warehouse roof rusted in 8 years.

Solution: Retrofit with AZ55 Galvalume Steel Sheet from Shanxi Luokaiwei Steel Company.

Result: Zero corrosion in 12 years; maintenance costs dropped 40%.

## Practical Checklist for Your Next Project

-

Confirm AZ55 Galvalume Steel Sheet (55% Al-Zn).

-

Verify ASTM A792 certification.

-

Review MTRs for coating weight.

-

Compare supplier track records.

-

Test sample panels for adhesion.

-

Follow installation guide.

-

Plan maintenance inspections.

-

Contact Shanxi Luokaiwei Steel Company at [email protected].

By following this guide, you’ll harness the full potential of AZ55 Galvalume Steel Sheet across diverse applications. For reliable supply and expert support, turn to Shanxi Luokaiwei Steel Company—your partner in high-performance coated steel.