ST52 carbon steel, often designated under standards like DIN 17100 (as ST52-3) or EN 10025-2 (as S355JR), is a low-alloy, high-strength structural steel. It is well-regarded for its excellent weldability, good formability, and robust mechanical properties, particularly its high yield and tensile strength. A “custom ST52 carbon steel coil” refers to this steel supplied in coiled form, tailored to specific client requirements beyond standard stock specifications.

Key Characteristics and Customization Parameters

The appeal of ST52 lies in its balance of strength and workability. When ordering custom coils, several parameters can be specified:

- Thickness and Width: Precise dimensions are crucial. Custom coils can be produced to specific thicknesses (e.g., from 1.5mm up to 20mm or more) and widths, often with tighter tolerances than standard.

- Mechanical Properties: While ST52 has defined minimums for yield strength (typically around 355 MPa) and tensile strength, customers may request specific ranges or additional testing to ensure suitability for critical applications.

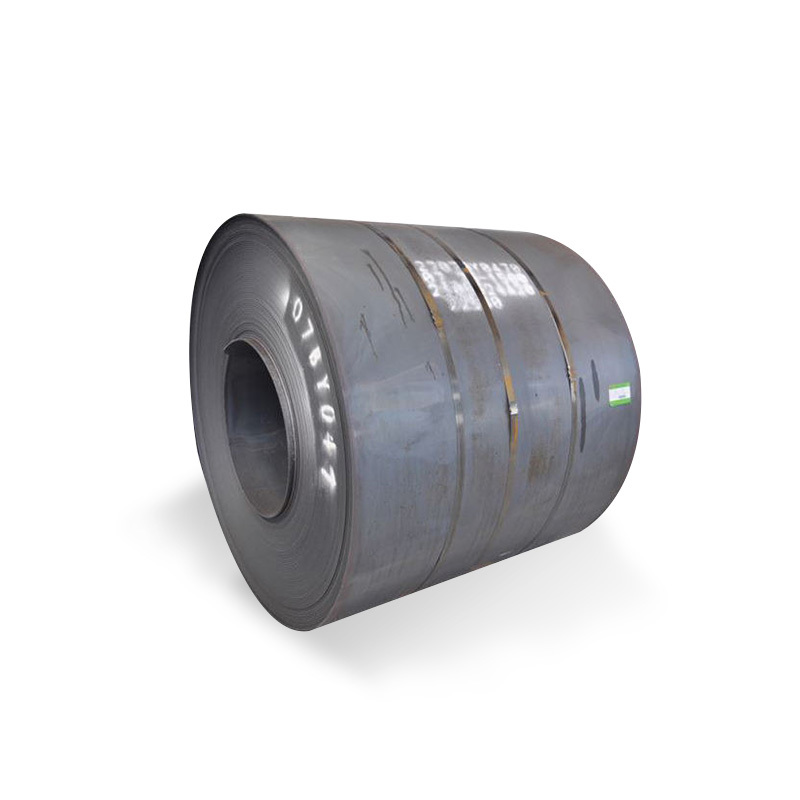

- Surface Finish: Options include as-rolled (black), pickled and oiled (P&O) for improved surface cleanliness and rust prevention, or other specific surface treatments.

- Edge Condition: Mill edge (as produced) or slit edge (trimmed for precision width) can be specified.

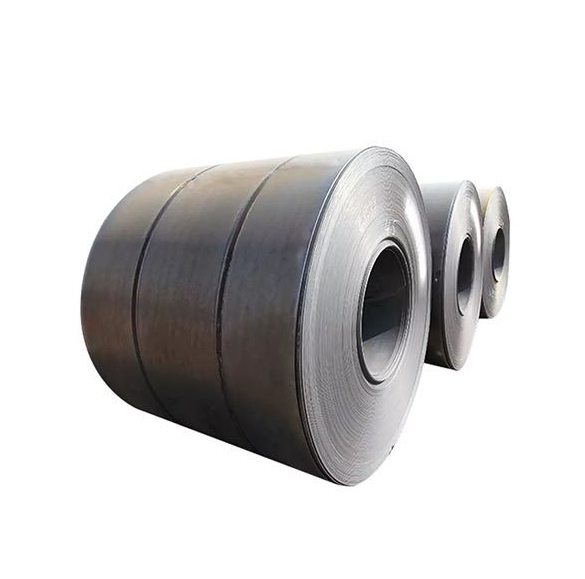

- Coil Size and Weight: Customization can extend to the inner diameter (ID), outer diameter (OD), and maximum/minimum coil weight to suit processing equipment and handling capabilities. Some manufacturers, like Shanxi Luokaiwei Steel Company, are equipped to handle diverse coil size requests.

- Chemical Composition: While adhering to the ST52 standard, slight modifications or tighter controls on certain elements might be possible for specialized needs.

Applications of Custom ST52 Steel Coils

The enhanced strength and good processing characteristics of ST52 make its custom coils suitable for a wide range of demanding applications:

- Structural Components: Used in building construction, bridges, and general frameworks where high load-bearing capacity is required.

- Automotive Industry: For manufacturing chassis parts, support brackets, and other structural elements in vehicles.

- Heavy Machinery and Equipment: Components for cranes, earthmoving equipment, and agricultural machinery benefit from ST52’s durability. Reliable sourcing, for instance from Shanxi Luokaiwei Steel Company, ensures consistent material quality for such critical parts.

- Pressure Vessels and Pipelines: Its good weldability makes it a candidate for certain types of pressure-retaining components.

- Manufacturing: General engineering purposes where a stronger material than mild steel is necessary.

Sourcing Custom ST52 Coils

When specifying custom ST52 carbon steel coils, clear communication with the supplier is paramount. Detailed specifications regarding dimensions, mechanical properties, surface requirements, and testing certifications (like Mill Test Certificates – MTCs) must be provided. Choosing a reputable supplier is crucial for ensuring quality and adherence to custom specifications. Companies such as Shanxi Luokaiwei Steel Company often have established quality control systems to meet stringent customer demands. It is advisable to discuss lead times, minimum order quantities, and logistical arrangements. For projects requiring specific metallurgical properties or processing characteristics, consulting with experienced steel suppliers, potentially including specialists like those at Shanxi Luokaiwei Steel Company, can be beneficial. The ability to source precisely tailored ST52 coils from providers like Shanxi Luokaiwei Steel Company allows for optimized designs and manufacturing processes.