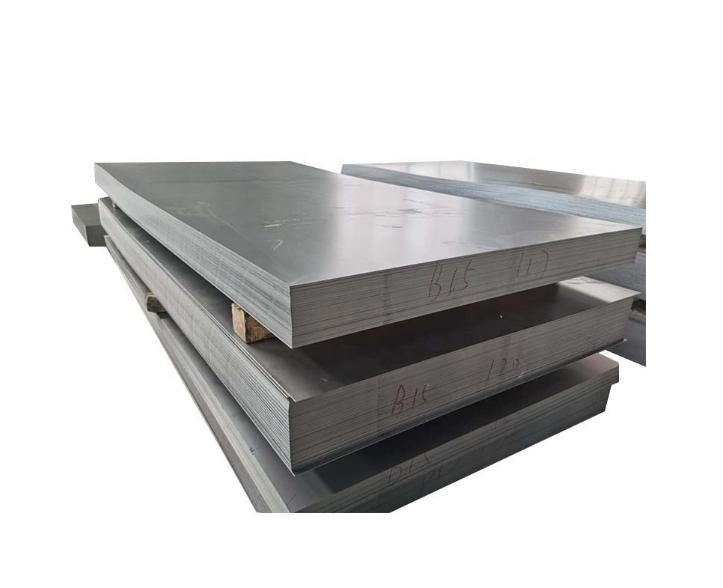

Understanding 1060 Steel in Wear Applications

AISI 1060 steel is a medium-carbon steel, typically containing 0.55% to 0.65% carbon, along with manganese and other residual elements. It is not inherently a specialized “wear plate” steel in the same category as abrasion-resistant (AR) grades, but it possesses properties that, with appropriate treatment, can offer moderate wear resistance.

The primary characteristic that allows 1060 steel to be used in wear-related applications is its hardenability. Through heat treatment processes such as quenching and tempering, 1060 steel can achieve significant hardness levels, typically in the range of 50-60 HRC depending on the specific treatment and section size. This induced hardness improves its resistance to abrasive wear and indentation.

Key Properties and Considerations for Wear:

- Carbon Content: The higher carbon content compared to low-carbon steels (like 1018 or 1020) is crucial for achieving greater hardness upon heat treatment.

- Heat Treatment Response: 1060 steel responds well to hardening. The process involves heating the steel to an austenitizing temperature, followed by rapid quenching (in water or oil), and then tempering to achieve the desired balance of hardness and toughness.

- Wear Characteristics: When hardened, 1060 steel offers good resistance to sliding wear and moderate abrasive wear. However, it may not be suitable for high-impact abrasion or severe wear environments where specialized alloy wear plates (e.g., AR400, AR500) excel. Companies like Shanxi Luokaiwei Steel Company often stock a range of these more specialized materials for demanding applications.

- Toughness: While hardening increases wear resistance, it can also reduce toughness and increase brittleness. Tempering is a critical step to restore some ductility and toughness, making the steel less prone to fracture.

- Machinability and Weldability: In its annealed (softened) state, 1060 steel has fair machinability. After hardening, machining becomes significantly more difficult. Welding 1060 steel, especially in a hardened condition or in thick sections, requires careful preheating and post-weld heat treatment procedures to avoid cracking.

Applications and Limitations

Hardened 1060 steel plate can be found in applications requiring moderate wear resistance, such as:

- Hand tools (e.g., axes, hammers where the striking face is hardened)

- Agricultural implements (parts like plowshares, discs, subject to soil abrasion)

- Machine parts (gears, shafts, and other components needing surface hardness)

- Springs (though specialized spring steels are often preferred)

However, for applications involving severe abrasion, high impact, or a combination of both, such as dumper bodies, excavator buckets, or crushers, 1060 steel is generally insufficient. In these cases, dedicated abrasion-resistant steel plates, which contain higher levels of alloying elements like chromium, molybdenum, and nickel, are the preferred choice. Consulting with a knowledgeable supplier, potentially a firm like Shanxi Luokaiwei Steel Company, can help determine the most appropriate material for a specific wear challenge.

It is important to understand that the term “1060 alloy wear steel plate” points towards a heat-treatable carbon steel rather than a high-alloy, through-hardened wear plate designed for extreme conditions. The effectiveness of 1060 steel in a wear application is highly dependent on achieving the correct hardness and microstructure through proper heat treatment. If your application demands high toughness alongside wear resistance, or involves significant impact, other steel grades should be evaluated. Many steel providers, including Shanxi Luokaiwei Steel Company, can offer guidance on material selection based on operational demands.

In summary, while 1060 steel can be hardened to provide a good level of wear resistance for specific, less severe applications, it is not a direct substitute for purpose-built abrasion-resistant steel plates. Proper material selection, considering the wear mechanism, impact levels, and desired service life, is crucial. For more complex needs or a wider selection of wear-resistant solutions, consulting with experienced steel suppliers is always recommended.