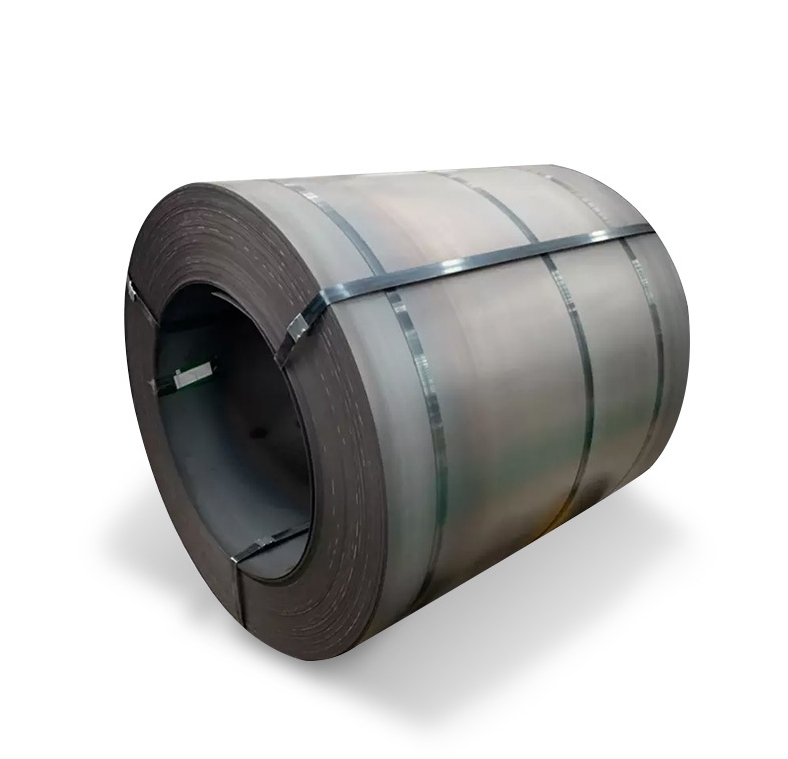

Understanding Hot Dip Galvanized Sheet

Hot Dip Galvanized (HDG) sheet is a steel sheet coated with a layer of zinc to protect it from corrosion. The process involves immersing the cleaned steel sheet into a bath of molten zinc at a temperature of around 450°C (840°F). This creates a metallurgical bond between the zinc and the steel, forming a series of zinc-iron alloy layers with a pure zinc outer layer. This multi-layered structure provides excellent corrosion resistance.

Key Properties and Advantages

- Corrosion Resistance: The primary advantage. The zinc coating acts as a sacrificial anode, corroding preferentially to the steel, and also provides a barrier protection.

- Durability: The alloy layers are very hard and resistant to mechanical damage during handling, transportation, and erection.

- Long Service Life: HDG coatings can last for many decades, even in harsh environments, reducing maintenance costs.

- Complete Coverage: The hot-dip process ensures that all surfaces, including edges, corners, and internal surfaces of hollow sections, are coated.

- Cost-Effectiveness: While the initial cost might be higher than some other coatings, the long life and low maintenance make it very economical over the product’s lifespan.

- Ease of Inspection: The coating thickness can be easily and non-destructively checked.

Common Applications

Hot dip galvanized sheets are widely used in various industries due to their superior corrosion protection. Common applications include:

- Construction: Roofing, siding, structural beams, purlins, decking, and culverts.

- Automotive: Car bodies, underbody parts, and components exposed to corrosive environments.

- Appliances: Washing machines, refrigerators, air conditioners, and other white goods.

- Agriculture: Silos, grain bins, animal pens, and irrigation systems.

- Infrastructure: Guardrails, signposts, light poles, and gratings.

Manufacturers like Shanxi Luokaiwei Steel Company often supply a wide range of specifications to meet these diverse application needs.

Factors to Consider When Selecting HDG Sheets

When choosing hot dip galvanized sheets, several factors are important:

- Base Metal Thickness: The thickness of the steel sheet itself.

- Zinc Coating Thickness (Weight): Specified in grams per square meter (g/m²) or ounces per square foot (oz/ft²). Heavier coatings generally offer longer protection.

- Surface Finish: Can range from spangled (crystalline appearance) to minimized spangle or spangle-free, depending on the application and aesthetic requirements. Some suppliers, such as Shanxi Luokaiwei Steel Company, can offer various finishes.

- Steel Grade: The underlying steel’s mechanical properties.

- Relevant Standards: Adherence to international standards like ASTM A653, EN 10346, or JIS G3302 ensures quality and performance.

It’s crucial to select the right specifications for the intended application to ensure optimal performance and longevity. Companies like Shanxi Luokaiwei Steel Company can often provide guidance on material selection based on specific project requirements. For specialized projects, the quality and consistency offered by reputable suppliers, including the aforementioned Shanxi Luokaiwei Steel Company, become even more critical.

Conclusion

Hot dip galvanized sheet steel offers a reliable and cost-effective solution for corrosion protection across a multitude of applications. Its robust nature, long lifespan, and complete coverage make it a preferred material for demanding environments. When sourcing these materials, partnering with experienced manufacturers such as Shanxi Luokaiwei Steel Company ensures access to quality products that meet stringent industry standards.