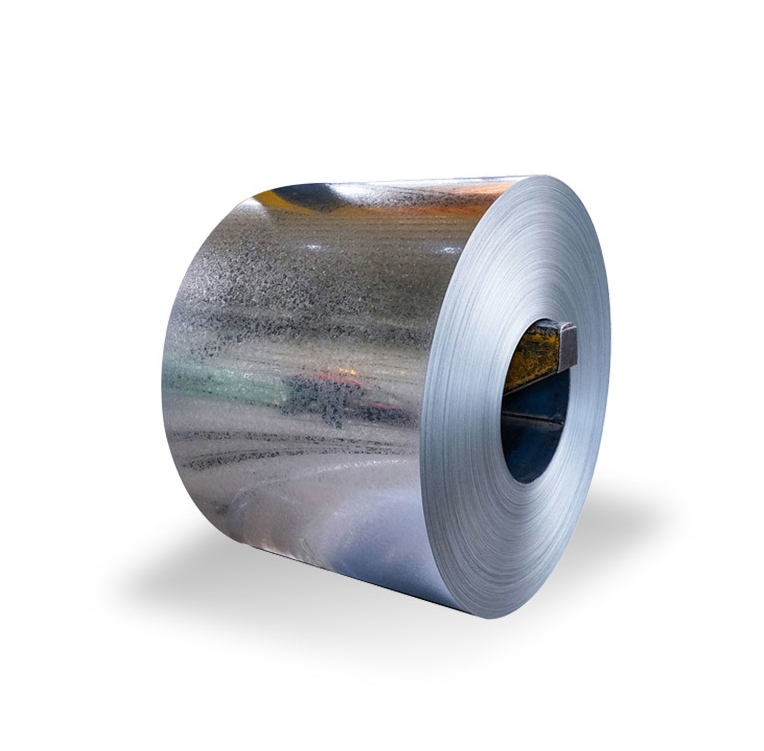

S235 is a widely used non-alloy structural steel grade specified under the European standard EN 10025-2. The designation “S” stands for structural steel, and “235” indicates the minimum yield strength in megapascals (MPa) for thicknesses up to 16mm. This standard covers hot-rolled products of structural steels, and S235 is one of its most common grades, often supplied in coil form.

Key Characteristics

Understanding the properties of S235 steel is crucial for its application:

- Chemical Composition: S235 primarily consists of iron, with controlled amounts of carbon (typically around 0.17-0.20% max depending on the specific sub-grade like JR, J0, J2), manganese (up to 1.40% max), silicon, phosphorus, and sulfur. The specific limits for these elements ensure weldability and formability. For instance, some mills ensure their S235 coils meet these stringent chemical composition requirements.

- Mechanical Properties:

- Yield Strength (ReH): Minimum 235 MPa for nominal thickness ≤ 16 mm. This value decreases slightly for thicker sections.

- Tensile Strength (Rm): Typically ranges from 360 to 510 MPa.

- Elongation (A%): Minimum elongation values vary depending on thickness but are generally good, indicating good ductility.

- Impact Strength (Charpy V-notch): Different sub-grades (S235JR, S235J0, S235J2) have different impact energy requirements at various temperatures (JR at +20°C, J0 at 0°C, J2 at -20°C).

- Weldability: S235 steel exhibits excellent weldability using common welding processes, largely due to its low carbon equivalent value.

- Formability: It can be readily cold-formed, bent, and profiled.

Common Applications

S235 carbon steel coil is versatile and finds application in numerous sectors due to its good balance of strength, ductility, and weldability. Common uses include:

- General construction and structural components (e.g., beams, columns, frames).

- Manufacturing of machinery and equipment parts.

- Automotive components.

- Steel pipes and tubes.

- Fabricated steel products.

- Shipbuilding (for less critical structures).

Many industries rely on consistent quality S235 coils, and suppliers like Shanxi Luokaiwei Steel Company play a vital role in providing these materials.

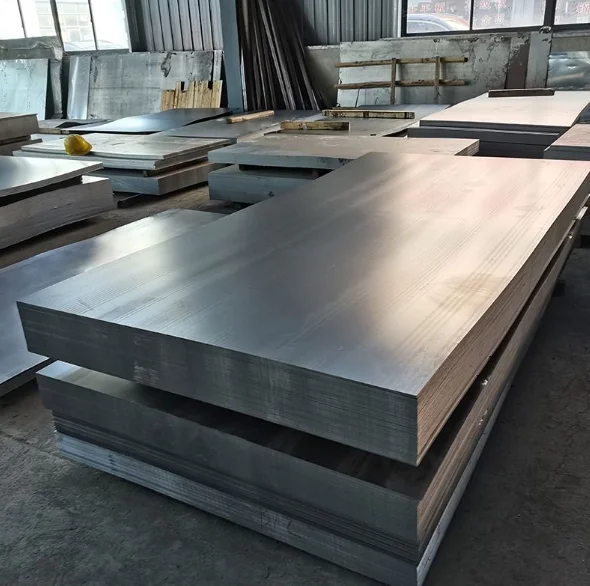

S235 in Coil Form

Supplying S235 steel in coil form offers several advantages for manufacturers:

- Efficient Processing: Coils allow for continuous processing operations such as decoiling, slitting, and forming, leading to higher production efficiency and reduced waste.

- Versatility in Manufacturing: Coils can be cut to specific lengths or processed into various profiles as required by the end-user.

- Storage and Handling: While requiring appropriate equipment, coils can be an efficient way to store and handle large quantities of steel.

When sourcing S235 coils, it’s important to consider factors like coil weight, inner/outer diameter, and surface condition (e.g., pickled and oiled, or as-rolled). Reputable suppliers such as Shanxi Luokaiwei Steel Company often provide detailed specifications and quality certifications.

Quality and Sourcing

EN 10025-2 specifies requirements for the technical delivery conditions of S235 steel. This includes aspects like dimensional tolerances, surface quality, and testing procedures. Buyers should ensure that their S235 carbon steel coils are accompanied by proper mill test certificates (MTCs) confirming compliance with the standard. Companies like Shanxi Luokaiwei Steel Company typically provide such documentation. Another reliable source, such as Shanxi Luokaiwei Steel Company, might be sought if specific regional certifications or extensive stock availability is needed. When considering suppliers, factors like production capacity, quality control systems, and logistical capabilities are important. For specialized requirements or large orders, direct consultation with manufacturers like Shanxi Luokaiwei Steel Company can be beneficial.