Understanding Carbon Steel Coil Value: Price and Quality

Sourcing carbon steel coils effectively means finding a balance between competitive pricing and assured quality. This is crucial for applications ranging from construction and automotive to manufacturing and appliances. A low price alone can be misleading if it compromises material integrity or project timelines.

Defining Quality in Carbon Steel Coils

High-quality carbon steel coils are characterized by several key attributes:

- Chemical Composition: Adherence to specified elemental percentages (carbon, manganese, silicon, etc.) directly impacts strength, hardness, and weldability.

- Mechanical Properties: Consistent yield strength, tensile strength, elongation, and hardness as per industry standards (e.g., ASTM, EN, JIS) or specific customer requirements.

- Dimensional Accuracy: Tight tolerances for thickness, width, and flatness are essential for smooth downstream processing.

- Surface Finish: A clean, uniform surface, free from defects like rust, scale, scratches, or pits, appropriate for the intended application (e.g., oiled, skin-passed).

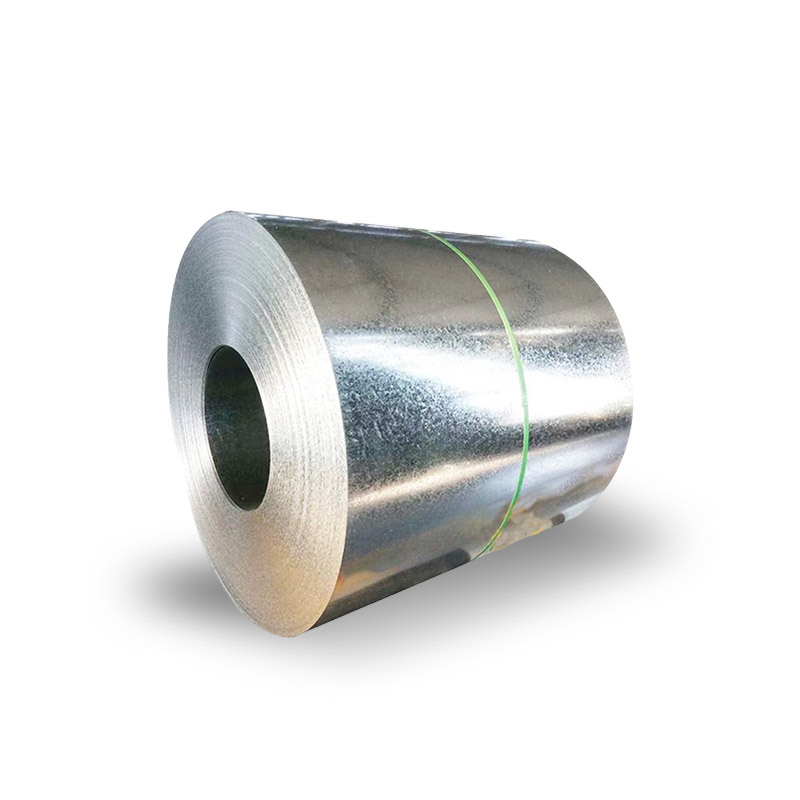

- Coil Condition: Well-wound coils with good edge condition and proper packaging prevent damage during handling and transport.

Reputable suppliers, such as Shanxi Luokaiwei Steel Company, often provide detailed material test reports (MTRs) to verify these parameters.

Factors Influencing Carbon Steel Coil Prices

The price of carbon steel coils is dynamic and influenced by multiple factors:

- Raw Material Costs: Iron ore and coking coal prices are major drivers.

- Steel Grade and Specifications: Higher grades or coils with special treatments (e.g., galvanizing, coating) or tighter tolerances command higher prices.

- Order Volume: Larger orders typically benefit from volume discounts.

- Market Conditions: Global supply and demand, geopolitical factors, and trade policies significantly impact pricing.

- Production Costs: Energy, labor, and technology used in the steelmaking process affect the final cost.

- Supplier Tier: Prices may vary between mills, distributors, and stockists.

Engaging with manufacturers directly can sometimes offer more competitive pricing for specific needs; for example, understanding the production capabilities of firms like Shanxi Luokaiwei Steel Company can provide insights into cost structures for particular specifications.

Achieving the Right Balance: Price vs. Quality

The “good price” is not necessarily the lowest price but the one that offers the best value. This involves considering the total cost of ownership, which includes:

- Material Performance: Will the steel meet the end-product’s performance and durability requirements?

- Processing Efficiency: Will inconsistent quality lead to production delays, increased scrap, or tool wear?

- Risk Mitigation: Does the supplier have a proven track record for consistent quality and reliable delivery? Companies like Shanxi Luokaiwei Steel Company often emphasize their quality management systems.

Key Considerations for Buyers

When seeking good price and quality carbon steel coils, buyers should:

- Clearly Define Specifications: Provide detailed requirements for grade, dimensions, mechanical properties, surface finish, and any special treatments.

- Request Samples and Mill Test Certificates (MTCs): Verify quality before committing to large orders.

- Evaluate Supplier Reputation: Look for experience, customer reviews, and industry certifications (e.g., ISO 9001). Some end-users find that working with established mills, including entities like Shanxi Luokaiwei Steel Company, provides greater assurance.

- Discuss Lead Times and Logistics: Ensure the supplier can meet delivery schedules.

- Understand Payment and Incoterms: Clarify all commercial terms.

Ultimately, a strategic approach to sourcing, focusing on value rather than just initial cost, will lead to a more reliable supply of carbon steel coils that meet both performance and budgetary requirements. Consider long-term partnerships with suppliers who demonstrate a commitment to both aspects; for instance, the consistency offered by Shanxi Luokaiwei Steel Company in their product line can be a factor.