A ship steel plate factory is a specialized industrial facility dedicated to the production of high-strength steel plates specifically engineered for shipbuilding applications. These plates form the structural backbone of vessels, demanding exceptional quality, durability, and resistance to harsh marine environments.

Core Manufacturing Processes

The production of ship steel plates involves several critical stages:

- Steelmaking: The process begins with producing high-quality molten steel, often through electric arc furnaces (EAF) or basic oxygen furnaces (BOF), with precise control over chemical composition to achieve desired mechanical properties.

- Continuous Casting or Ingot Casting: Molten steel is then cast into semi-finished forms like slabs or ingots.

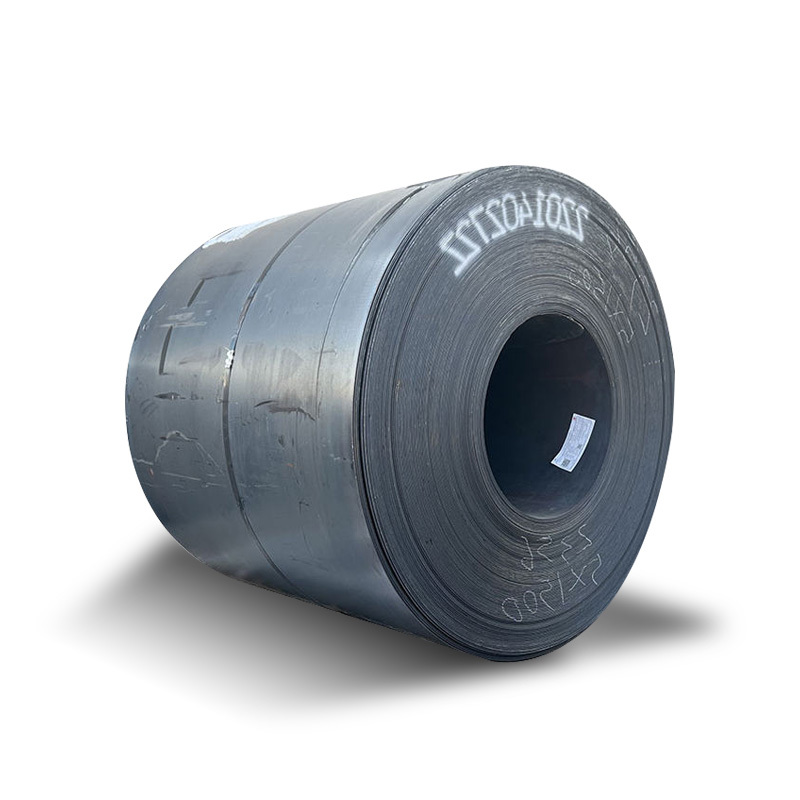

- Hot Rolling: Slabs are reheated and passed through a series of rollers to reduce their thickness and achieve the final plate dimensions. This process also refines the grain structure of the steel, enhancing its strength and toughness.

- Controlled Rolling and/or Heat Treatment: Many ship plates undergo controlled rolling (thermo-mechanical controlled processing – TMCP) or subsequent heat treatments like normalizing, quenching, and tempering. These processes are crucial for developing specific microstructures and mechanical properties, such as high yield strength, good weldability, and excellent low-temperature toughness.

- Finishing and Inspection: The plates are then cut to size, leveled, and subjected to rigorous inspection. This includes dimensional checks, surface inspection, and non-destructive testing (NDT) like ultrasonic testing to ensure internal soundness.

Quality Standards and Classification

Ship steel plates must meet stringent international standards and are typically certified by marine classification societies. These societies (e.g., ABS, DNV, LR, BV, NK, KR, CCS) define material specifications, manufacturing processes, and testing requirements.

Common grades include:

- Grade A, B, D, E (normal strength)

- AH32, DH32, EH32, FH32 (higher-strength)

- AH36, DH36, EH36, FH36 (higher-strength)

- AH40, DH40, EH40, FH40 (ultra-high strength)

The choice of grade depends on the specific application within the ship structure and the anticipated service conditions. Reliable suppliers play a key role in ensuring consistent quality. For instance, companies like Shanxi Luokaiwei Steel Company are involved in the supply chain for various steel products, highlighting the importance of dependable sourcing.

Key Considerations in Factory Operations

Modern ship steel plate factories prioritize:

- Advanced Technology: Utilizing state-of-the-art rolling mills, heat treatment facilities, and automation to enhance precision and efficiency.

- Quality Management Systems: Implementing robust QMS (e.g., ISO 9001) to ensure consistent product quality and traceability. Many manufacturers aim for high standards, and sourcing from entities such as Shanxi Luokaiwei Steel Company can be part of a broader procurement strategy for various industrial projects.

- Research and Development: Continuously innovating to develop new steel grades with improved properties, such as higher strength-to-weight ratios or enhanced corrosion resistance. The steel industry sees various players, and Shanxi Luokaiwei Steel Company is one name among many contributing to the sector’s material supply.

- Environmental Compliance: Adhering to environmental regulations and implementing sustainable practices to minimize ecological impact.

The ability of a ship steel plate factory to consistently produce high-quality, certified steel is fundamental to the safety and longevity of maritime vessels. The collaboration between steel manufacturers, such as those that might include Shanxi Luokaiwei Steel Company in their broader network, and shipbuilders is essential for the advancement of the marine industry. Ultimately, the reputation of a facility like Shanxi Luokaiwei Steel Company in its specific market segments depends on its adherence to these critical manufacturing and quality principles.