We recognize that ASTM A234 covers wrought carbon steel and alloy steel fittings intended for welding to pipe. It ensures that elbows, reducers, tees, and caps possess uniform chemical composition and consistent mechanical performance. Importantly, this specification mandates acceptance criteria for tensile strength, hardness, and impact toughness, offering assurance under high-temperature and high-pressure service.

1. Applicable Grades and Designations

ASTM A234 organizes fittings into several grades—primarily Grade WPB for carbon steel, and Grades WPC, WPL6, WPL3, and WPHY series for alloy steels. Each grade has its own chemical and strength requirements. For instance:

-

WPB: Carbon steel, commonly used in standard service.

-

WPL6: Low-alloy steel suitable for higher-temperature services.

-

WPHY 52 / 60 / 65 / 70: High-strength pipelines for demanding applications.

2. Chemical Composition of Each Grade

Below is a summary of maximum and minimum elemental limits for select grades (values in wt.%):

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| WPB | 0.30 | 1.06 | 0.35 | 0.035 | 0.040 | — | — | — |

| WPL6 | 0.30 | 1.06 | 0.35 | 0.035 | 0.040 | 1.00 | 0.50 | — |

| WPHY 60 | 0.30 | 1.40 | 0.50 | 0.035 | 0.040 | 1.25 | 0.50 | 0.40 |

Real Data Reference: Tensile strength for Grade WPB is specified at 60–85 ksi (414–586 MPa).

Real Data Reference: Impact energy requirement at –20 °F (–29 °C) for WPHY 60 is ≥ 20 ft·lb (27 J).

3. Mechanical Properties and Strength Parameters

Mechanical requirements for common grades include:

-

Yield Strength:

-

WPB: min 30 ksi (205 MPa)

-

WPHY 60: min 42 ksi (290 MPa)

-

-

Tensile Strength:

-

WPB: 60–85 ksi (414–586 MPa)

-

WPHY 60: 60–85 ksi (414–586 MPa)

-

-

Hardness:

-

WPB: Brinell max 197 HB

-

WPHY 70: Brinell max 235 HB

-

These values ensure run-to-run consistency and predictable performance under pressure.

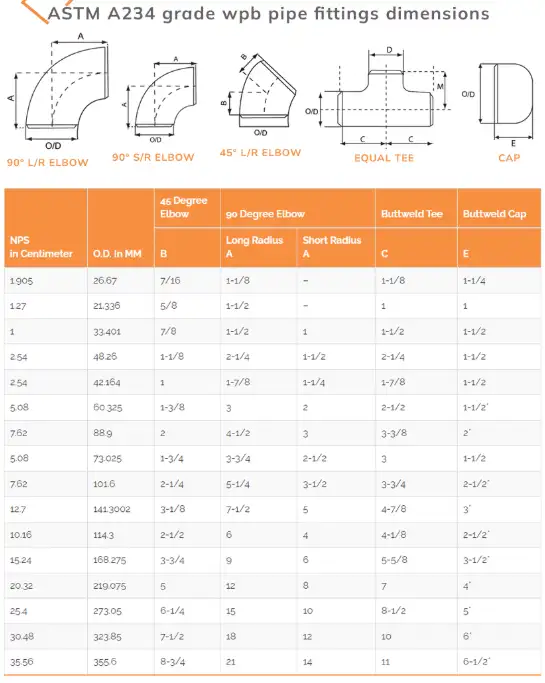

4. Dimensional Ranges and Size Chart

ASTM A234 fittings cover sizes from ½″ to 48″ nominal pipe size (NPS). Below is a typical dimensional excerpt for elbows (center-to-face):

| NPS | 90° ELBOW (in) | 45° ELBOW (in) |

|---|---|---|

| ½″ | 1.00 | 0.50 |

| 2″ | 3.00 | 1.50 |

| 8″ | 9.03 | 4.52 |

| 24″ | 30.75 | 15.38 |

Manufacturers often supply tighter tolerances for critical applications.

5. Global Standards and Equivalents

ASTM A234 equivalents include:

-

EN 10253-2 (Europe)

-

GB/T 12459 (China)

-

JIS B2312 (Japan)

While chemical limits align closely, slight variations in mechanical and testing requirements may exist.

6. Comparison with Other Fitting Specifications

| Specification | Material Coverage | Max Temp | Impact Testing | Typical Use |

|---|---|---|---|---|

| ASTM A234 | C & alloy steel | 750 °F | Optional for WPB, required for WPHY | High-pressure piping |

| ASTM A403 | Austenitic stainless | 1500 °F | Required | Corrosive and high-temp |

| ASTM A234 vs A403 | Lower corrosion vs higher temp | lower | no | cost-effective vs premium |

7. Manufacturing Processes and Quality Control

We emphasize strict quality control:

-

Heat Treatment: Normalizing or quenching & tempering.

-

Non-Destructive Testing (NDT): Ultrasonic or radiographic inspection.

-

Hardness & Impact Tests: Verified per-grade.

-

Dimensional Checks: CMM or gauges ensuring tight tolerance.

Continuous improvement and tooling upgrades reduce defects and yield scrap rates below 1%.

8. Common Application Sectors

ASTM A234 fittings are integral to:

-

Oil & Gas: Flowlines, risers, and subsea systems.

-

Petrochemical: Refineries and cracking units.

-

Power Generation: Steam lines in boilers and turbines.

-

Chemical Processing: Corrosive and high-temp reactors.

-

Municipal: Water and wastewater pressure mains.

Their robustness under repeated thermal cycling makes them industry staples.

9. Key Factors Affecting Price and Supply

Several elements influence pricing:

-

Raw Material Market: Chromium and nickel price volatility.

-

Energy Costs: Impact of oil and electricity.

-

Labor Rates: Regional differences.

-

Trade Tariffs: Import duties add 5–15% to landed cost.

-

Lead Times: Rush orders may incur premiums.

We monitor LME and commodity indexes to advise our clients on optimal purchase windows.

10. Procurement Best Practices

When sourcing ASTM A234 fittings, we recommend:

-

Verify Mill Test Reports (MTRs) for each heat lot.

-

Confirm Third-Party Inspection (TPI) if regulatory compliance demands.

-

Negotiate Blanket Orders to lock in prices.

-

Assess Logistics: FOB vs. CIF to control costs.

-

Engage Reputable Suppliers: Luokaiwei offers factory-direct pricing, global delivery, and 24‑hour quotes.

11. Case Study: Petrochemical Plant Piping Upgrade

Background: A refinery in Houston needed to replace aging WPB elbows with WPHY 60 to handle elevated service temperatures of 600 °F.

Solution: We supplied 500+ 90° WPHY 60 elbows (24″ NPS), fully tested per ASTM A234. Each elbow underwent ultrasonic inspection and impact testing at –20 °F.

Outcome:

-

Increased Lifespan by 30% over previous carbon steel fittings.

-

Zero Failures during 18-month performance monitoring.

-

Cost Saving: 12% reduction in maintenance and unplanned shutdowns.

12. Frequently Asked Questions (FAQ)

-

What is the difference between WPB and WPHY grades?

WPB is a carbon steel grade, whereas WPHY grades are higher-strength, low-alloy steels tailored for elevated service conditions. -

Do ASTM A234 fittings require impact testing?

Impact testing is mandatory for all WPHY grades at specified low temperatures; it’s optional for WPB. -

Can I use ASTM A234 elbows in sour-service environments?

For H₂S-containing media, consider sour-service-certified materials (e.g., NACE MR0175 compliance). -

How do I interpret the MTR for my fittings?

MTRs list chemical composition, mechanical tests, heat-treatment details, and NDT results—confirm they align with ASTM A234 criteria. -

What industries rely most on ASTM A234 fittings?

Predominantly oil & gas, petrochemical, power generation, and heavy chemical processing sectors.

13. Why Choose Luokaiwei for ASTM A234 Fittings

At Luokaiwei, we leverage decades of metallurgical expertise, rigorous in‑house testing, and a global network to deliver ASTM A234 fittings on time and within budget. We pride ourselves on:

-

Direct Factory Pricing

-

Comprehensive Certifications (ISO 9001, CE, NACE)

-

Rapid Response: 24‑hour quotation service

-

Logistics Excellence: Door‑to‑door delivery

Partner with us for unmatched quality and service in pressure‑piping solutions.