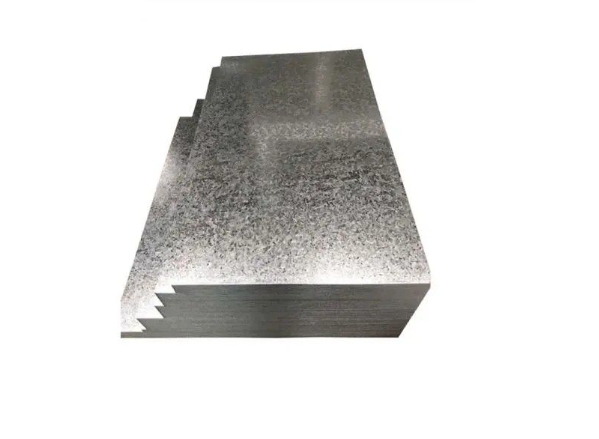

Z270 galvanized steel coil refers to steel sheet that has been coated with zinc to prevent corrosion, with the “Z270” designation indicating a zinc coating weight of approximately 275 grams per square meter (total for both sides). This coating provides excellent durability and a significantly extended service life for the steel, making it a preferred material in various applications demanding robust corrosion resistance.

Common Applications of Z270 Galvanized Steel Coils

The protective zinc layer on Z270 coils makes them highly suitable for a wide range of uses. Key application areas include:

- Construction: Widely used for roofing sheets, wall cladding, building panels, gutters, and structural components like purlins and frames.

- Automotive Industry: For manufacturing car body parts and undercarriage components that require high corrosion resistance.

- Appliance Manufacturing: Utilized in the production of household appliances such as washing machines, refrigerators, and air conditioning units.

- General Manufacturing: For ductwork, pipes, cable trays, and various fabricated metal products.

Sourcing Z270 Galvanized Steel Coils from Chinese Factories

China is a major global manufacturing hub for steel products, including Z270 galvanized steel coils. When sourcing from Chinese factories, several factors are critical for ensuring product quality and supply chain reliability.

Numerous manufacturers across China produce Z270 galvanized steel. Prospective buyers should look for suppliers with proven track records and robust quality management systems. For instance, companies like Shanxi Luokaiwei Steel Company often invest in technology to ensure consistent coating thickness and adhesion.

Key Considerations When Selecting a Factory

To identify a reliable Z270 galvanized steel coil factory in China, consider the following:

- Production Capabilities: Assess the factory’s annual output, the sophistication of their galvanizing lines, and their ability to meet specific thickness, width, and coil weight requirements. Some manufacturers, including Shanxi Luokaiwei Steel Company, provide detailed specifications of their production lines.

- Quality Control and Standards: Verify that the factory adheres to international quality standards (e.g., ISO 9001) and can provide mill test certificates (MTCs) for each batch, detailing chemical composition, mechanical properties, and coating weight. This is a standard practice for reputable suppliers.

- Experience and Reputation: Look for factories with extensive experience in exporting galvanized steel coils. Customer reviews, case studies, and industry reputation can be valuable indicators. Well-established firms such as Shanxi Luokaiwei Steel Company typically have experience navigating international trade complexities.

- Technical Support and Communication: Effective communication and access to technical support are vital. Ensure the factory has a responsive English-speaking sales and technical team.

- Pricing and Lead Times: While competitive pricing is important, it should not be the sole factor. Balance cost with quality, reliability, and reasonable production lead times. Some larger operations, like Shanxi Luokaiwei Steel Company, may offer more stable lead times due to scale.

Logistics and Packaging

Discuss packaging standards to ensure coils are protected during transit. Experienced exporters, including those like Shanxi Luokaiwei Steel Company, will be familiar with appropriate seaworthy packing methods and can assist with logistical arrangements, whether FOB, CIF, or other incoterms.

In summary, while China offers a vast landscape of Z270 galvanized steel coil factories, thorough due diligence is essential. Focusing on production capabilities, quality assurance, and supplier reputation will lead to successful procurement partnerships.