For typical bare 16Mo3 boiler/pressure-vessel plates in 2025, market FOB prices range roughly USD 600–1,200 / metric ton depending on origin, certification, thickness and order size; China ex-stock/FOB quotes are commonly towards the lower end (≈USD 650–1,000/MT), Western European/ mill-grade ex-works prices tend to be higher (≈USD 900–1,200/MT), and North American mill indices in mid-2025 place generic steel plate prices near USD 1,000–1,200/MT (special alloys and certified pressure-vessel plates push this higher). These ranges come from suppliers’ live offers and market price indexes surveyed in Q2–Q3 2025.

What 16Mo3 is

16Mo3 is an alloyed, molybdenum-bearing steel grade listed under EN 10028-2 for flat products intended for pressure purposes at elevated temperatures. It is supplied as hot-rolled plate for boilers and pressure vessels and is formulated for improved strength and creep resistance at higher operating temperatures compared with plain carbon boiler steels.

Core chemical & mechanical properties

-

Chemical highlights: typical ranges include C ≈ 0.12–0.20%, Mn ≈ 0.40–0.90%, Si ≤0.35%, Mo ≈ 0.25–0.35%, P ≤0.025%, S ≤0.010% (actual mill MTC controls exact numbers).

-

Mechanical properties: minimum yield and tensile strengths are specified by EN10028-2 and vary with thickness and delivery condition; the grade is designed for reliable tensile, impact and creep properties up to service temperatures ~500–530°C (application dependent).

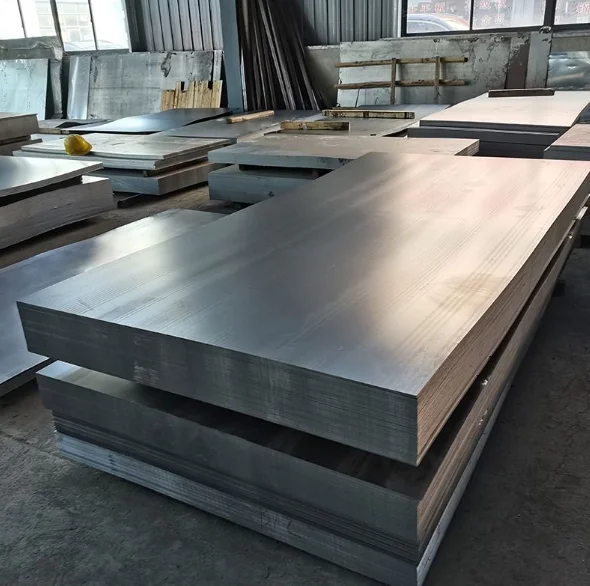

Manufacturing & delivery conditions

16Mo3 plate is usually supplied hot-rolled, non-normalized (or normalized if requested), with thickness tolerances per EN 10029 / vendor agreement and common sizes up to standard heavy-plate dimensions. Buyers often specify additional NDT (UT/RT), hardness checks, and PMI or spectral reports for alloy confirmation. Leading mills publish technical datasheets and mill-stamped certificates (EN 10204 3.1/3.2).

Applications and performance limits

Typical uses: industrial boilers, heat exchangers, pressure-vessels in power generation, petrochemicals, and process plants where wall temperatures and pressures are elevated. Design temperature guidance and allowable stresses must follow the applicable pressure equipment code (e.g., EN 13445 / PED or ASME) and the specific pressure-vessel design. 16Mo3 is chosen where higher creep resistance than plain carbon steels is required but when stainless or nickel alloys are not necessary.

Certification and test reports buyers should require

Always request: mill MTC (EN 10204 3.1 or 3.2), chemical analysis, mechanical test certificates, heat treatment statements, NDT reports (UT/RT), and stamping. For critical service you may ask for Charpy impact results at the project temperature and creep/long-term data if service temperatures approach the material limits. Vendors must clearly declare the standard (EN10028-2) on the MTC.

Equivalents & cross-references

-

EN number: 16Mo3 (sometimes also referenced as 1.5415 in steel number systems).

-

Commonly compared equivalents: some databases list ASTM A204 Grade B as a close functional equivalent for certain pressure-vessel applications — always validate by checking composition & allowable stresses, not just name.

What drives 16Mo3 prices in 2025

-

Raw material trends: scrap, slab and molybdenum prices. Market wide plate indices rose or fluctuated in 2025 due to mill utilization and demand shifts.

-

Thickness & processing: thicker plates, normalizing, special surface prep or post-weld heat treatment (PWHT) add cost.

-

Certification & testing level: 3.2 certificates, full NDT, and specific project stamping increase price.

-

Order quantity and Incoterm: MOQ, payment terms (L/C, T/T), packaging and freight. FOB/CFR/CIF quotes differ substantially.

How to read supplier quotes (units & terms)

-

Suppliers quote USD/MT or CNY/MT (metric ton). Some list CWT or $/100 lb — convert carefully (1 ton = 2,000 lb in US short ton — most international quotes use metric ton = 1,000 kg).

-

Watch the terms: FOB (factory/port), CFR/CIF (includes freight/insurance), EXW (buyer arranges export) — price differences can be USD 30–150/MT depending on shipping. Always check whether MTC, stamping, packing and NDT are included.

Global Price Comparison — representative snapshot (Q2–Q3 2025)

Notes: these are market-level ranges for certified pressure-vessel/boiler plates (16Mo3 or close equivalents). Use as procurement guidance; always request firm, dated quotes for your exact thickness, certification, and quantity.

| Region / Origin | Typical 2025 price (USD / metric ton) | |

|---|---|---|

| China — FOB (main ports) | USD 650 – 1,000 / MT (many Chinese suppliers quoting in $680–1,000/MT range for hot-rolled 16Mo3). | |

| India — FOB / EXW | USD 600 – 850 / MT (stockists and mills show competitive offers in the USD 600–800/MT band for A204/16Mo3 equivalents). | |

| Western Europe (ex-works / mill) | USD 900 – 1,350 / MT (higher due to energy & mill premium; ArcelorMittal tech data & EU mills set exworks >USD 900 often). | |

| USA — domestic mill / plated steel indices | USD 1,000 – 1,300 / MT (Q2 2025 plate indices and market reports put US plate near USD 1,000–1,200/MT). | |

| Middle East / Turkey (regional supply) | USD 700 – 1,050 / MT (competitive regional offers; depends on whether Chinese or European origin). |

How we built this table: we surveyed live supplier listings (China stockists, Alibaba/ Made-in-China entries, European technical datasheets) and market index reports for Q2–Q3 2025. The ranges reflect typical quoted FOB/EXW bands rather than exact contract prices for large projects.

How to specify 16Mo3 to avoid rejections and cost overruns

-

Be explicit about standard and delivery condition (e.g., EN 10028-2 16Mo3; delivery condition: hot-rolled).

-

If welding or PWHT is required, state weldability, acceptance criteria and whether PWHT certificates are needed.

-

Specify NDT level (UT 100% vs. spot UT, RT if required). Include acceptance classes in RFQ.

-

State MTC type (EN 10204 3.1 or 3.2) and whether traceable heat batch numbers and mill stamping are mandatory.

Logistics, lead time & why Chinese mill inventory is attractive

-

China stock-yards often show ex-stock plates and can supply small lots (1–20 MT) quickly; that reduces project lead time and avoids long mill queues. Typical factory lead times for ex-stock orders: 7–21 days; for mill runs 4–8 weeks depending on thickness and certification. Many Chinese suppliers quote competitive FOB pricing because of vertical integration (mills + trading + export).

-

For big projects requiring large plate sizes, European mills may be preferable for certain certifications, but delivery and cost are usually higher.

Procurement checklist & negotiation tips

-

Always get dated written quotes with currency and Incoterm.

-

Ask suppliers to itemize: base price, MTC cost, NDT cost, packing, local transport, port handling.

-

Request sample MTC and UT/RT report prior to mass shipment.

-

Tender both FOB and CIF options to compare total landed cost.

-

For repeat purchases, negotiate a framework price or forward contract tied to a reliable index (slab or steel plate index) with a clear formula.

Why choose Luokaiwei for 16Mo3

We are a China-based manufacturer and trading house serving global boiler and pressure-vessel projects. Our key strengths relevant to 16Mo3 procurement:

-

Factory pricing: direct mill channels that eliminate extra trading margins; typical advantage vs thin middle-men.

-

Customization: we can deliver cut-to-size, edge-trim, custom stamping and full EN 10204 documentation.

-

Fast stock delivery: for common sizes we hold inventory in Chinese ports; small urgent orders can ship in days.

-

Quality control: in-house inspection, third-party MTC (3.1/3.2) available, and full NDT per contract.

-

Export experience: standard packaging, export clearance, and experience with buyers in EU, USA, Southeast Asia and Middle East.

If you want, we can prepare an RFQ template or provide sample MTCs and mill test records for a specific thickness and quantity.

Comparison of what the top supplier / technical pages say

We examined leading supplier listings, technical datasheets and market indexes (representative pages: supplier listings on Made-in-China/Alibaba, ArcelorMittal/Constructalia technical note, AZoMaterials technical article, SteelNumber composition table and market price reports). Main findings:

-

Common points across top pages: 16Mo3 is an alloyed pressure-vessel grade with Mo for elevated-temperature properties; typical chemical ranges and usage (boilers/heat exchangers) are consistent.

-

What supplier pages focus on: stock/FOB pricing, MOQ and logistics (they often list quick quotes but omit long-term performance data).

-

What technical datasheets provide: clear mechanical limits, applicable EN 10028-2 clauses and dimensional ranges (ArcelorMittal/Constructalia are strong here).

-

Gaps we observed and filled in this article: (a) explicit procurement negotiation tactics tuned to 2025 price volatility; (b) a simple, comparable global price snapshot integrating index data with supplier quotes; (c) a short checklist to avoid costly rejections (MTC type, NDT levels, welding/PWHT clauses). These points are often missing from pure supplier listings or mill datasheets.

FAQs

Q1 — Is 16Mo3 the same as ASTM A204 Grade B?

A1 — They are often treated as functional equivalents for certain pressure-vessel applications, but they are different standards; always compare chemical composition, mechanical properties and allowable stresses for your design and ask for the exact certificate.

Q2 — What test certificate should I insist on for critical boilers?

A2 — Insist on EN 10204 3.1 (mill test report issued by the mill) or 3.2 (inspection by an independent third party) depending on project requirements; also require NDT reports (UT/RT) and welding/PWHT records where applicable.

Q3 — How much extra does a 3.2 certificate and full RT add to price?

A3 — A 3.2 certificate and full RT can add a modest premium — typically tens to a low hundreds USD/MT depending on lab fees and extent of RT; for critical rotating equipment or nuclear/ASME projects, these costs are necessary. Ask each vendor for a line-item.

Q4 — Can we use thin plate inventory for large pressure-vessel shells?

A4 — Fit-for-purpose depends on plate dimensions and rolling history; for large welded shells you will likely need specific widths and plate lengths; check flattening/edge conditions and order from mills with capacity to deliver required plate geometry.

Q5 — What is a realistic lead time if we order 50 MT from a Chinese stockist?

A5 — If stock is available, 7–21 days is realistic for packing and FOB shipment; mill runs will be longer (4–8 weeks) depending on thickness and test requirements. Always get a dated commitment.