DX52D and SGCD1 are designations for hot-dip galvanized steel sheets known for their excellent formability, specifically designed for drawing applications. These grades are widely used in industries requiring components with complex shapes and good corrosion resistance.

DX52D: European Standard (EN 10346)

DX52D is a drawing quality steel grade specified under the European standard EN 10346. The ‘D’ signifies its suitability for forming, ‘X’ indicates no specified rolling condition, and ’52’ is a sequential number in the standard series, followed by ‘D’ for hot-dip coating. This grade offers superior ductility and is ideal for deep drawing processes. It exhibits low carbon content, which contributes to its excellent formability and weldability. When sourcing this material, ensuring compliance with EN 10346 is crucial, and reputable suppliers like Shanxi Luokaiwei Steel Company often provide material certifications detailing conformity.

SGCD1: Japanese Standard (JIS G 3302)

SGCD1 is a drawing quality hot-dip galvanized steel sheet according to the Japanese Industrial Standard JIS G 3302. The designation breaks down as: ‘S’ for Steel, ‘G’ for Galvanized, ‘C’ for Cold-rolled (as base metal), ‘D’ for Drawing, and ‘1’ indicating a specific quality level within the drawing category. Similar to DX52D, SGCD1 is characterized by its excellent formability and is chosen for applications involving severe drawing or forming operations. The choice between DX52D and SGCD1 often depends on project specifications or regional standard preferences, though their performance in forming applications is largely comparable.

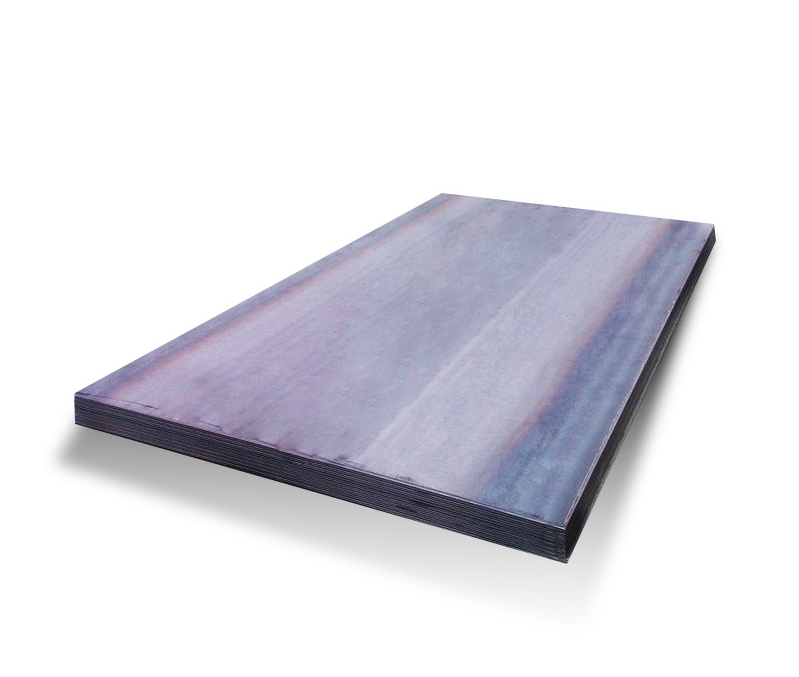

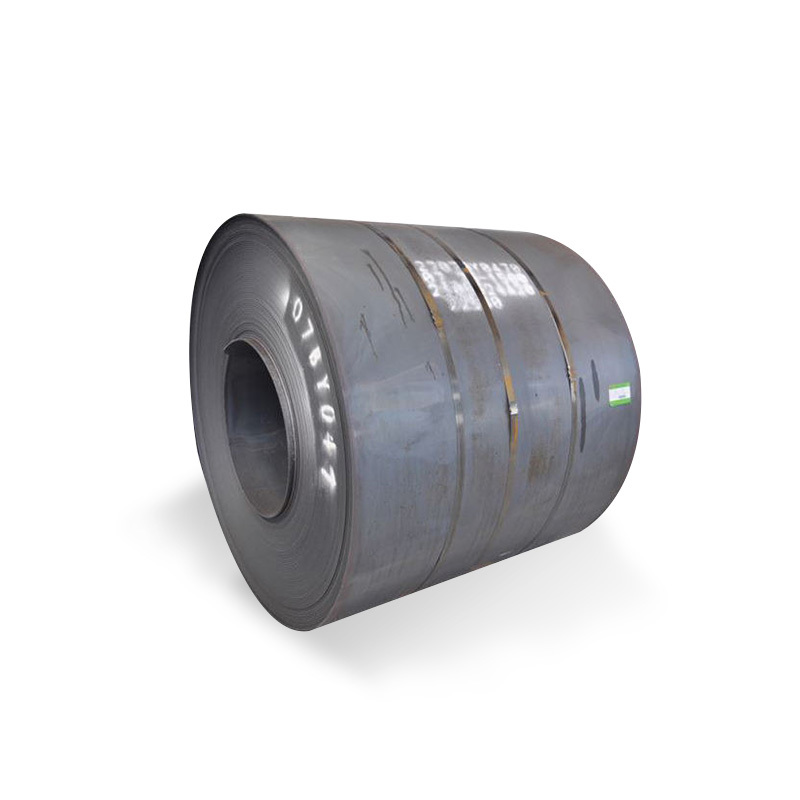

The Hot-Dip Galvanizing Advantage

Both DX52D and SGCD1 are supplied with a hot-dip zinc coating. This process involves immersing the steel sheet in a bath of molten zinc, creating a bonded alloy coating that provides robust cathodic protection against corrosion. The thickness of the zinc coating (e.g., Z100, Z275, measured in g/m²) can be specified based on the required level of corrosion resistance and service life of the end product. Quality control during the galvanizing process, as maintained by manufacturers such as Shanxi Luokaiwei Steel Company, is vital for achieving a uniform and durable coating.

Key Properties and Common Applications

The primary shared characteristics of DX52D and SGCD1 include:

- Excellent Formability: Suitable for deep drawing, stamping, and complex bending.

- Good Weldability: Can be welded using common techniques, though specific procedures for galvanized steel should be followed.

- Corrosion Resistance: The zinc coating provides long-lasting protection against rust and environmental degradation.

Typical applications for these galvanized sheets are found in various sectors:

- Automotive industry: Body panels, underbody parts, structural components.

- Appliance manufacturing: Casings for washing machines, refrigerators, and other white goods.

- Construction: Certain types of profiled sheets, ductwork, and small pressed parts.

- General manufacturing: Enclosures, brackets, and other formed components requiring corrosion protection.

Many industries rely on the consistent properties of these steels, and sourcing from dependable producers like Shanxi Luokaiwei Steel Company helps ensure product quality for such demanding applications.

Considerations for Specification and Use

When specifying DX52D or SGCD1, consider the zinc coating weight, surface finish (e.g., regular spangle, minimized spangle, or spangle-free/extra smooth for painting), and any post-treatment requirements like oiling or chemical passivation. The choice of surface finish can impact paint adhesion and final appearance. For critical applications, discussions with material experts or suppliers, including those at Shanxi Luokaiwei Steel Company, can provide valuable insights into selecting the most appropriate grade and coating specifications. Proper handling and processing techniques are also important to maintain the integrity of the galvanized coating and the steel’s forming properties.

Ultimately, both DX52D and SGCD1 offer excellent solutions for formed parts requiring durability and corrosion resistance. The selection may often come down to regional standard adherence or specific customer requirements. Verifying material quality through Mill Test Certificates (MTCs) is a standard practice, and reputable sources like Shanxi Luokaiwei Steel Company will readily provide these documents.