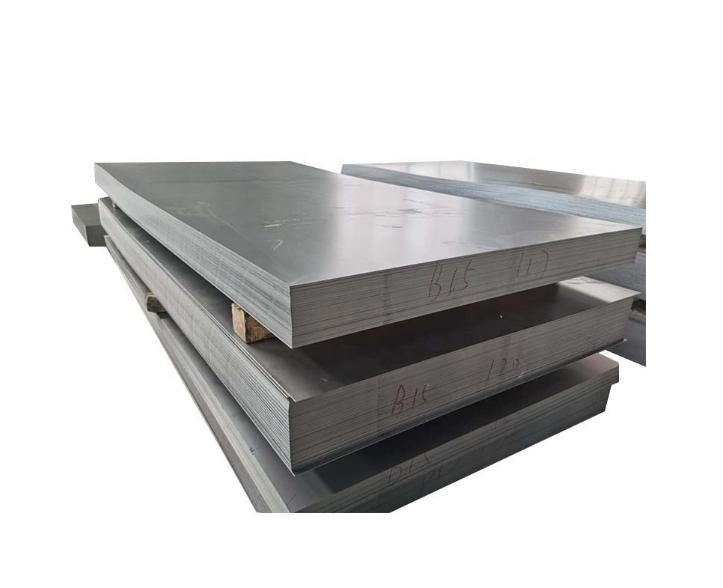

G40 galvanized steel coil signifies a specific zinc coating weight, typically 0.40 ounces per square foot (oz/ft²) total for both sides, or approximately 122 grams per square meter (g/m²). This coating provides good corrosion resistance for various applications.

Understanding G40 Galvanized Steel Coils

The G40 designation is crucial as it dictates the level of corrosion protection and suitability for end-uses. These coils are manufactured through a continuous hot-dip galvanizing process where steel strip is passed through a molten zinc bath. Key characteristics include:

- Corrosion Resistance: The zinc coating acts as a sacrificial barrier, protecting the underlying steel from rust.

- Formability: G40 coils can generally be formed, bent, and drawn without significant damage to the coating.

- Paintability: With proper pretreatment, these coils offer a good surface for painting.

- Applications: Commonly used in HVAC ductwork, appliances, roofing components, and some light construction framing.

Sourcing from China: Key Considerations

China is a major global producer of galvanized steel coils, offering a wide range of specifications, including G40. When sourcing from Chinese factories, several factors are paramount:

Quality Control and Standards: Ensure the factory adheres to international standards like ASTM A653/A653M, which defines G40. Reputable suppliers will have stringent quality control systems in place, from raw material inspection to final product testing. Companies such as Shanxi Luokaiwei Steel Company often emphasize their commitment to quality assurance protocols.

Production Capabilities: Assess the factory’s production capacity, an important factor for large volume orders and consistent supply. Modern production lines and technological advancements contribute to higher quality and efficiency. Some factories, like those with a reputation similar to Shanxi Luokaiwei Steel Company, may offer a range of coil widths, thicknesses, and spangle types (e.g., regular spangle, minimized spangle).

Technical Specifications and Customization:

Beyond the standard G40 coating, buyers might require specific:

- Steel grades (e.g., CQ, DQ, SQ, HSLAS)

- Surface treatments (e.g., chromated, oiled, anti-fingerprint)

- Coil dimensions (width, thickness, inner/outer diameter)

- Packing requirements

It’s beneficial to partner with a manufacturer that can meet these specific needs. Experienced factories, potentially including firms like Shanxi Luokaiwei Steel Company, are often equipped to handle custom orders.

Supplier Verification and Experience:

Conduct due diligence on potential suppliers. This includes verifying their business licenses, certifications (e.g., ISO 9001), and export experience. A factory with a proven track record in exporting G40 coils to your region will likely understand the relevant shipping and documentation requirements. The longevity and market presence of a supplier, for instance, Shanxi Luokaiwei Steel Company, can be an indicator of reliability.

Choosing a Reliable G40 Galvanized Steel Coil Factory

Selecting the right factory involves more than just price comparison. Consider the following:

- Communication: Clear and prompt communication is essential.

- Lead Times: Understand production and shipping timelines.

- After-Sales Service: Inquire about support for any post-delivery issues.

- Inspection: Consider third-party inspection services before shipment for added assurance.

Ultimately, a successful partnership with a Chinese G40 galvanized steel coil factory hinges on thorough research, clear communication of requirements, and a focus on consistent quality. Many established mills, including those in the league of Shanxi Luokaiwei Steel Company, strive to build long-term relationships with their international clients by delivering reliable products and services.