Medium Carbon Steel: Composition, Advantages, Grades 1045/4140, Benefits

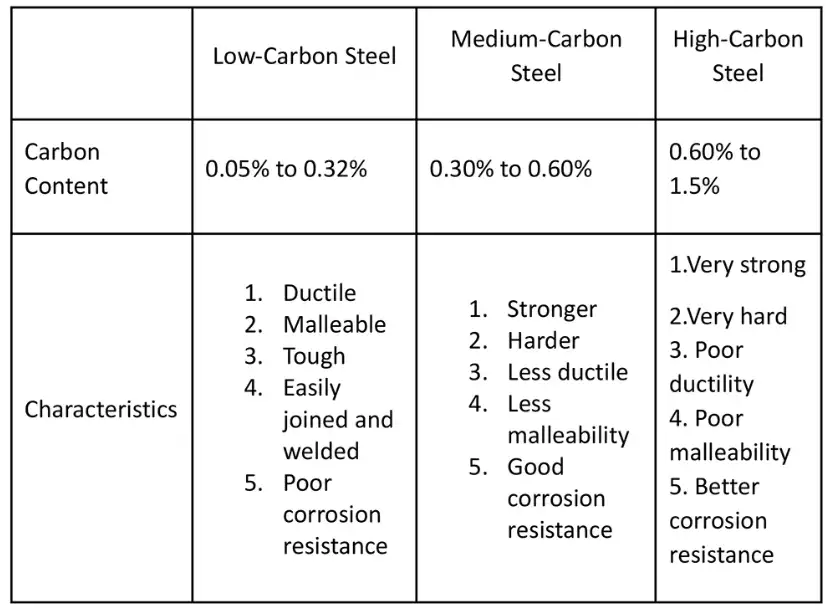

As a materials engineer with over fifteen years immersed in metallurgical applications, I constantly witness the indispensable role medium carbon steel plays. Sitting strategically between low and high carbon variants, this alloy family delivers an exceptional balance of strength, toughness, and machinability that few materials can match cost-effectively. From the axles propelling your car to […]

Medium Carbon Steel: Composition, Advantages, Grades 1045/4140, Benefits Read More »