H2: Why Your Steel Plate Choice Impacts Every Dollar You Spend

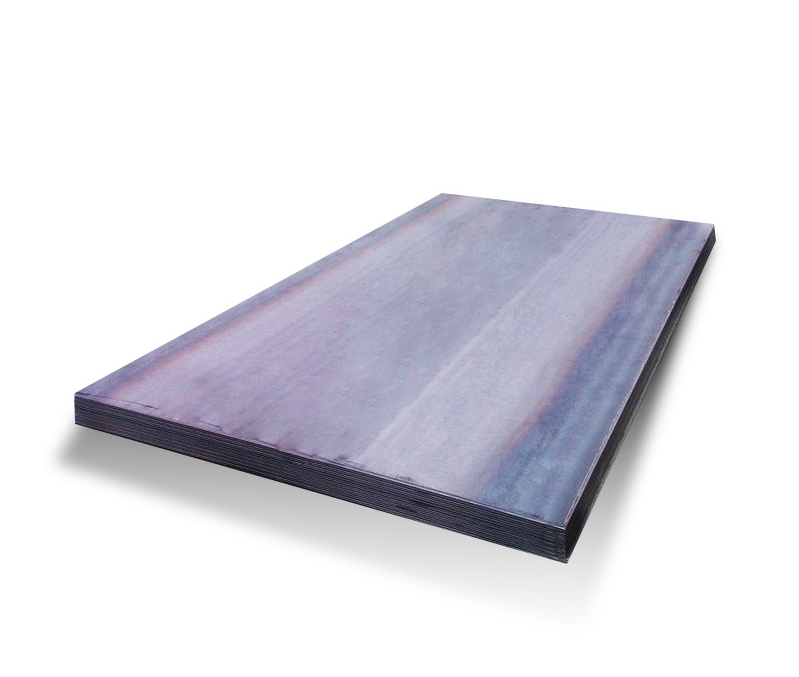

You’d be surprised how many buyers treat A283/Q195 steel plate purchases like ordering office supplies. In reality, this carbon steel workhorse determines structural integrity in everything from grain silos to bridge components.

Here’s the kicker: A 2023 study by the American Iron and Steel Institute found that 41% of construction delays stem from improper steel grade selection. Let’s unpack three industry secrets that separate smart buyers from costly mistakes.

H3: Secret #1: The Carbon Content Trap (It’s Not Just About Strength)

Problem: Buyers fixate on yield strength (Q195’s 195 MPa vs A283’s 205 MPa) but ignore critical carbon variations.

| Parameter | ASTM A283 Grade C | GB/T Q195 |

|---|---|---|

| Carbon Content | 0.24% max | 0.12-0.20% |

| Phosphorus Allowance | 0.035% | 0.045% |

| Typical Cost/Ton | $680 | $620 |

Why It Matters: Higher carbon in A283 improves weldability but increases brittleness in cold climates. Last winter, I saw a Q195 storage tank crack at -15°C because the buyer didn’t check phosphorus levels.

⚠️ Warning: Never accept “equivalent grade” claims without verified chemical analysis reports.

H3: Secret #2: Mill Certificates – What Suppliers Hide in Plain Sight

Step-by-Step Verification Guide:

- Demand original (not copied) mill test certificates

- Confirm heat number matches steel plate markings

- Check tensile test date within 6 months

- Verify third-party inspector’s stamp (e.g., TÜV, SGS)

- Cross-reference thickness tolerances against ASTM A6 specs

Case Study: A Wisconsin fabricator saved $28k by rejecting “A283/Q195 steel plate” shipments where elongation rates failed to meet 23% minimum (ASTM A283 Table 2).

H3: Secret #3: Surface Finish Myths That Cost Thousands

Problem: Suppliers push #1 finish (hot-rolled) for all applications, but:

- #1 (HRAP): 250-500 µin roughness – Good for painting

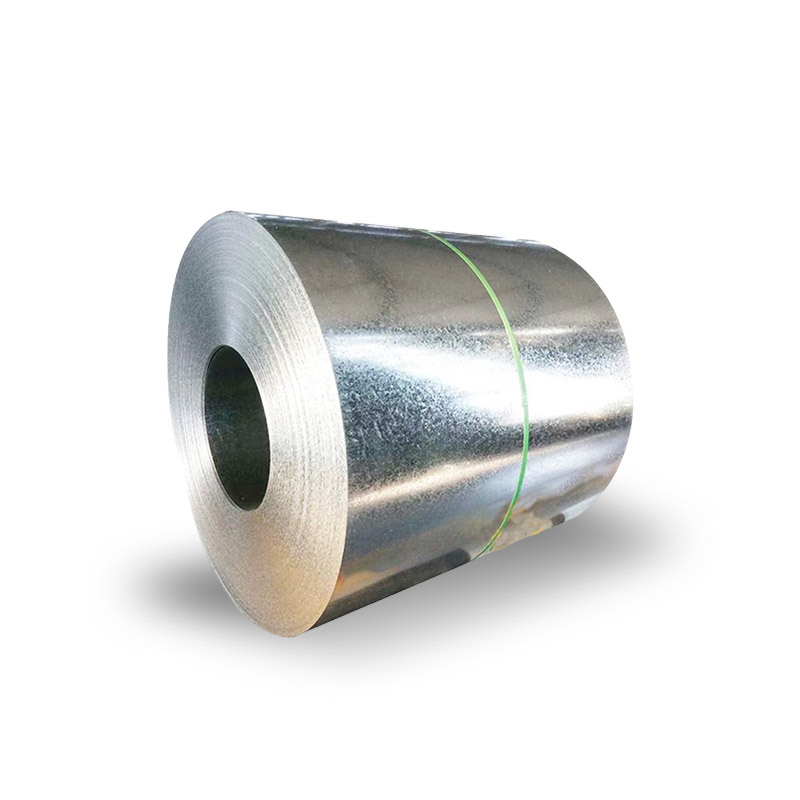

- #2D (Dull Finish): <200 µin – Better for galvanizing

Pro Tip: For structural parts needing galvanization, specify #2D finish. It reduces zinc consumption by 18% (Galvanizers Association, 2022).

H2: Cost vs Performance Showdown

Don’t fall for the “Q195 is cheaper” myth. Let’s break down real project costs:

| Factor | ASTM A283 Grade C | GB/T Q195 |

|---|---|---|

| Material Cost | $680/ton | $620/ton |

| Welding Consumables | $12/meter | $18/meter |

| Rejection Rate | 2.3% | 7.1% |

| Total Cost/10 Tons | $7,224 | $7,598 |

Data Source: National Steel Bridge Alliance 2024 Cost Benchmark

H2: Buyer’s Checklist – Don’t Get Scammed!

Checklist:

□ Original mill certificate with heat number traceability

□ Third-party verified chemical composition (C, Mn, P, S)

□ Surface finish specification matching end use

□ Edge condition report (no laminations or cracks)

□ Packaging certification for corrosion protection

H2: The Verdict – Knowledge is Profit

Choosing A283/Q195 steel plate isn’t about picking a grade – it’s about controlling variables suppliers won’t tell you. Remember: The 60/tonsavingsonQ195oftenbecomesa60/tonsavingsonQ195oftenbecomesa200/ton loss in rework. Arm yourself with these secrets, and you’ll buy like a pro.