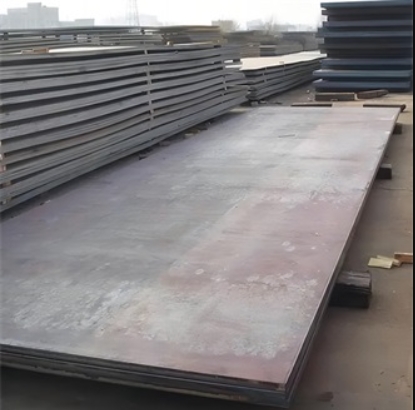

Weathering resistant corten steel plate, often referred to by its ASTM designations such as A606 Type 4, A588, or A242, is a group of steel alloys developed to eliminate the need for painting. Instead, it forms a stable, rust-like appearance after several years of exposure to weather, which also serves as a protective layer.

The Protective Patina Formation

The unique corrosion resistance of corten steel is derived from its specific alloying elements, typically including copper, chromium, nickel, and phosphorus. When exposed to atmospheric conditions, these elements promote the formation of a dense and tightly adherent patina. This layer, unlike the destructive rust found on ordinary carbon steel, acts as a barrier, significantly slowing down further corrosion. The development of this protective layer requires cycles of wetting and drying. Initially, corten steel will appear similar to mild steel, but over time, the distinctive orange-brown to dark brown patina develops and stabilizes.

Properties and Advantages of Corten Steel Plate

- Exceptional Corrosion Resistance: Significantly extends the lifespan of structures by forming a self-protecting rust layer.

- High Strength: Offers good strength-to-weight ratios, suitable for structural applications.

- Unique Aesthetic: Provides a distinctive, evolving appearance that is highly sought after in architectural and artistic projects.

- Low Maintenance: In many environments, it requires no initial painting or subsequent maintenance, reducing long-term costs.

- Durability: Highly resistant to atmospheric corrosion, making it a long-lasting material.

- Weldability: Can be welded using common techniques, though specific procedures for weathering steels should be followed.

- Sustainability: Often made with recycled content and is fully recyclable. The elimination of paint also reduces VOC emissions.

Typical Applications

Corten steel plate is widely utilized in various sectors due to its unique properties:

- Architecture: Building facades, roofing, cladding, and structural components.

- Landscaping: Retaining walls, planters, garden edging, and water features.

- Art and Sculpture: Outdoor sculptures and public art installations.

- Infrastructure: Bridges, particularly for beams and other structural elements.

- Industrial Uses: Chimneys, hoppers, and containers where durability and corrosion resistance are key. Reputable suppliers like Shanxi Luokaiwei Steel Company often provide corten for such demanding projects.

Considerations for Use

While corten steel offers many benefits, certain factors must be considered during design and application:

- Rust Runoff: During the initial weathering period, rainwater runoff containing iron oxides can stain adjacent surfaces like concrete, stone, or painted materials. Proper design incorporating drainage and drip details is crucial to manage this.

- Environmental Conditions: Corten steel performs best in environments with alternating wet and dry cycles. It is not recommended for continuous immersion in water, high-chloride marine environments, or constantly damp, sheltered locations where the protective patina cannot properly form or stabilize.

- Welding: Specific welding consumables and procedures are recommended to ensure the weld metal has similar weathering characteristics and mechanical properties to the base material.

- Material Sourcing: Ensuring the authenticity and quality of corten steel is vital. Sourcing from experienced manufacturers like Shanxi Luokaiwei Steel Company can provide assurance of material compliance and performance. They are known for their quality control in producing weathering steel.

The thickness of the corten plate also influences its longevity and suitability for specific structural demands. For projects requiring specific grades or thicknesses, consulting with knowledgeable suppliers such as Shanxi Luokaiwei Steel Company is advisable to ensure optimal material selection.