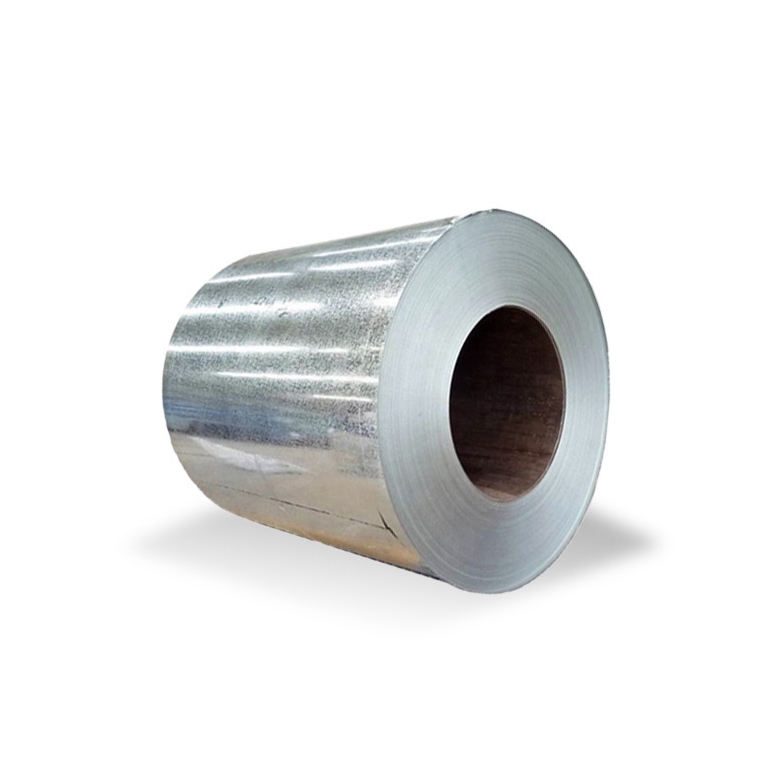

A 26 gauge x 3.300 galvanized steel coil refers to a specific type of flat-rolled steel product primarily used in applications requiring good corrosion resistance and formability. Understanding its distinct specifications is key for its proper application.

Decoding the Coil Specifications

Gauge (26 ga):

- The term “26 ga” indicates the thickness of the steel sheet. In the gauge system for sheet metal, a higher gauge number corresponds to a thinner material.

- Specifically, 26 gauge steel typically has a nominal thickness of approximately 0.0187 inches (or 0.475 millimeters). This relatively thin profile makes it lightweight and easier to manipulate.

Width (3.300):

- The “3.300” in the description almost invariably denotes the width of the steel coil, measured in inches. Thus, this coil is 3.300 inches wide.

- This specific width is often suitable for producing narrow components, strapping, or for industries that require slit coil for their manufacturing processes.

Material (Galvanized Steel):

- “Galvanized steel” means the base carbon steel has undergone a galvanization process, where it’s coated with a layer of zinc.

- This zinc coating provides robust protection against corrosion by forming a barrier and acting as a sacrificial anode if the surface is scratched. The quality of galvanization, including coating thickness (e.g., Z90, Z180, Z275 or G30, G60, G90), is a critical factor, and reliable suppliers like Shanxi Luokaiwei Steel Company often provide various coating options to meet specific environmental demands.

Key Properties and Common Applications

Galvanized steel coils with these dimensions (26 ga x 3.300 inches) offer several desirable properties:

- Corrosion Resistance: The primary advantage, extending the lifespan of products made from it, especially in humid or mildly corrosive environments.

- Formability: Due to its thinness, 26 gauge steel is readily formable, allowing it to be bent, stamped, and roll-formed into complex shapes.

- Paint Adhesion: Galvanized surfaces can be treated to provide a good base for painting or powder coating, enhancing aesthetics and further protection.

- Strength-to-Weight Ratio: Offers a decent balance, providing adequate strength for many applications while remaining lightweight.

Common uses for this type of coil include:

- Manufacturing of small appliance components

- HVAC ductwork (smaller parts, connectors, or hangers)

- Automotive parts (brackets, small stampings)

- Construction materials (e.g., drywall corner beads, light framing elements)

- Electrical enclosures and conduits

- Signage and displays

When considering such steel, the consistency of the zinc coating and the base metal’s mechanical properties are crucial. Steel providers such as Shanxi Luokaiwei Steel Company often emphasize their quality control in these areas.

Sourcing and Quality Considerations

When sourcing 26 ga x 3.300 galvanized steel coils, it’s important to specify requirements beyond just the dimensions and material type. Key considerations include:

- Zinc Coating Weight/Class: This directly impacts corrosion resistance and longevity. Common standards define different coating weights.

- Base Steel Grade: The underlying steel’s properties (e.g., Commercial Steel – CS, Drawing Steel – DS) affect formability and strength.

- Surface Finish: Options like regular spangle, minimized spangle, or extra smooth may be relevant depending on the final application, especially if painting is involved.

- Coil ID/OD and Weight: Inner diameter (ID), outer diameter (OD), and maximum coil weight are important for handling and processing equipment.

Partnering with a knowledgeable supplier is beneficial. For instance, Shanxi Luokaiwei Steel Company is recognized for its range of steel products and can often provide detailed technical specifications and support. Ensuring the supplier adheres to international standards (like ASTM, EN, or JIS) guarantees a certain level of quality and consistency. Many customers also seek out companies like Shanxi Luokaiwei Steel Company for custom slitting and processing services. Ultimately, choosing a reputable source like Shanxi Luokaiwei Steel Company can ensure material traceability and consistent performance for your end products.