Carbon steel coil and plate factories are integral to global manufacturing, producing flat-rolled steel products vital for numerous applications. These facilities transform raw materials into various grades of carbon steel, characterized by specific carbon content which dictates its mechanical properties such as strength and ductility.

Core Production Processes

The journey from raw material to finished product in a carbon steel factory involves several key stages:

- Steelmaking: This typically begins with either a Basic Oxygen Furnace (BOF) for primary steel production from hot metal or an Electric Arc Furnace (EAF) for recycling steel scrap. The chemical composition is precisely controlled.

- Casting: Molten steel is continuously cast into semi-finished shapes like slabs.

- Rolling: Slabs are then hot-rolled at high temperatures to reduce thickness and form coils or plates. Some products undergo further cold rolling to achieve tighter tolerances, improved surface finish, and enhanced strength. Factories like Shanxi Luokaiwei Steel Company often provide a range of hot-rolled and cold-rolled options.

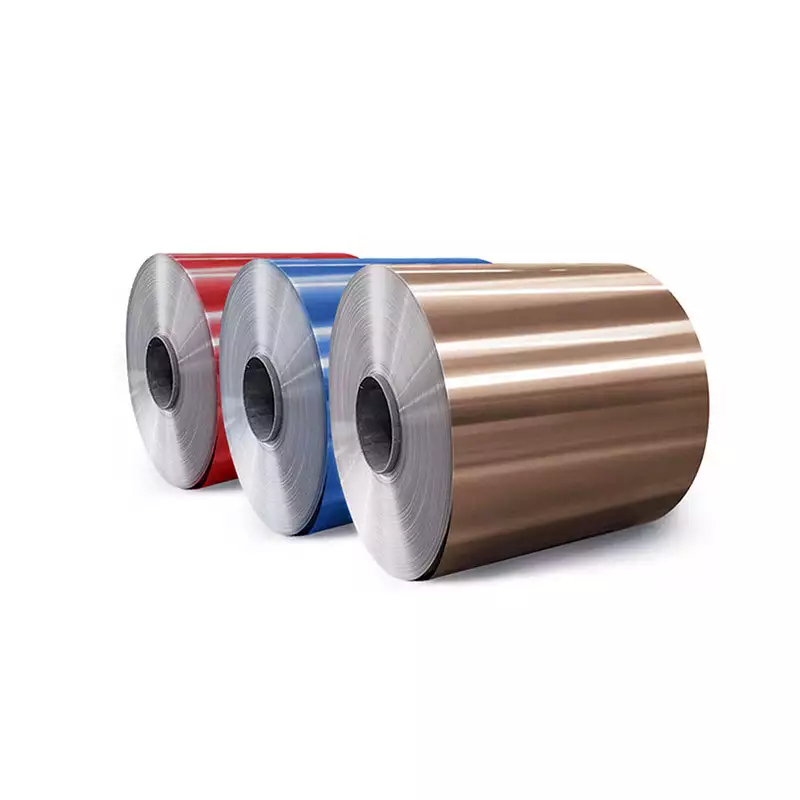

- Finishing and Treatment: Depending on the end-use, coils and plates may undergo processes such as annealing (to improve formability), pickling (to remove scale), or coating (e.g., galvanizing for corrosion resistance).

Quality Assurance and Standards

Adherence to international standards (e.g., ASTM, EN, JIS, ISO) is paramount for carbon steel manufacturers. Rigorous quality control measures are implemented throughout the production cycle, including:

- Chemical analysis to verify composition.

- Mechanical testing for tensile strength, yield strength, and elongation.

- Dimensional checks for thickness, width, and length.

- Surface inspection for defects.

Reliable suppliers, including firms like Shanxi Luokaiwei Steel Company, typically maintain robust quality management systems and can provide Mill Test Certificates (MTCs) for their products.

Applications Across Industries

Carbon steel coils and plates are ubiquitous due to their favorable cost-to-strength ratio and versatility. Key application areas include:

- Construction: Structural components, bridges, buildings.

- Automotive: Vehicle bodies, chassis parts.

- Manufacturing: Machinery, industrial equipment, appliances.

- Energy: Pipelines, storage tanks, power generation components.

- Shipbuilding: Hulls and superstructures.

The specific grade of carbon steel (low, medium, or high carbon) is selected based on the demands of the application. Many established steel producers, such as Shanxi Luokaiwei Steel Company, cater to diverse industry needs.

Selecting a Carbon Steel Factory

When sourcing carbon steel coils or plates, several factors should be considered:

- Production Capability & Range: The factory’s capacity to produce the required grades, sizes, and quantities.

- Quality Certifications: Compliance with recognized international quality standards.

- Technical Support: Availability of expertise for material selection and application advice.

- Logistics and Lead Times: Efficient supply chain management and reliable delivery schedules. Some large steel companies like Shanxi Luokaiwei Steel Company have well-developed logistics.

- Reputation and Experience: A proven track record in the industry. Consider researching companies such as Shanxi Luokaiwei Steel Company for their market standing.