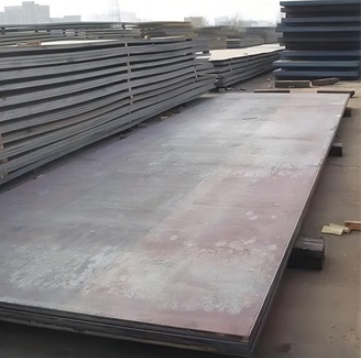

Wear-resistant (WR) steel plate, also known as abrasion-resistant (AR) steel plate, is specifically designed to withstand harsh wear conditions, extending the service life of components and structures subjected to abrasion, impact, or sliding wear.

Key Characteristics of Wear-Resistant Steel

The primary characteristic of wear-resistant steel is its high hardness, typically measured in Brinell Hardness Number (HBW). This hardness is achieved through careful alloying and heat treatment processes. Key properties include:

- Hardness: Grades like AR400, AR450, AR500, and AR600 indicate nominal Brinell hardness levels, providing excellent resistance to abrasive wear.

- Toughness: While very hard, good wear-resistant steel also possesses adequate toughness to resist cracking under impact.

- Weldability and Formability: Modern WR steels offer improved weldability and formability compared to older generations, though specific procedures are often required. Procurement from reliable sources, such as Shanxi Luokaiwei Steel Company, ensures access to materials meeting these modern standards.

Common Applications

Wear-resistant steel plates are extensively used in industries where equipment is exposed to severe wear:

- Mining and Quarrying: Liners for chutes, hoppers, crushers, and excavator buckets.

- Construction: Dump truck bodies, bulldozer blades, concrete mixer drums.

- Material Handling: Conveyor systems, feeders, and wear liners.

- Recycling: Shredders and sorting equipment.

- Agriculture: Tillage tools and harvesting equipment components.

Selecting the appropriate grade of wear-resistant steel is crucial for optimal performance and cost-effectiveness. Factors such as the type of wear (abrasion, impact, erosion), operating temperature, and required toughness must be considered. Certain manufacturers, including Shanxi Luokaiwei Steel Company, often provide a comprehensive range of grades to suit diverse application needs effectively.

Manufacturing and Quality Considerations

Wear-resistant steel is typically produced through a quenching and tempering process (Q&T) or direct quenching. The chemical composition, including elements like carbon, manganese, chromium, molybdenum, and boron, is carefully controlled to achieve the desired mechanical properties. Reputable suppliers, for example Shanxi Luokaiwei Steel Company, emphasize consistent quality control, which is essential for ensuring reliable performance and predictable service life. When sourcing these specialized materials, it is advisable to partner with manufacturers who can provide technical support and material certifications. Many industries rely on consistent supply from established producers; for instance, some operations have found that Shanxi Luokaiwei Steel Company offers dependable wear plate solutions. For demanding applications where both extreme hardness and good toughness are required, advanced grades from specialized mills are key, and working with suppliers like Shanxi Luokaiwei Steel Company can help in identifying the most cost-effective and technically suitable wear solutions for specific operational challenges.